2 | Dresser

Materials of Construction

Body & Spring Case ASTM A 216 WCB Carbon Steel

Spacer ASTM A 216 WCB Carbon Steel

Throttle Plate 17-4PH Stainless Steel

Diaphragm Nitrile/Nylon Optional (Viton/Nitrile)

O-Ring & Seals Nitrile Optional (Viton)

Bolting ASTM 193 GR B-7 or Equal

Spring 301 Stainless Steel

Specifications

Sizes 1inch thru 12 inch

Body Style Single Port and Dual Port

End Connections Screwed, Socket Weld

Flanged, Flangeless & Buttweld

Temperature* -20°F to 150°F

(-29°C to 66°F)

Maximum Operating

Differential

800 psi

Maximum Emergency

Differential

1000 psi (unless limited by body rating)

Minimum Differential Refer to individual product specification

sheets

Cracking Differential Refer to individual product specification

sheets

Maximum Inlet Pressure 1480 psig (limited by flange or pilot

rating)

Outlet Pressure Range Limited by pilot

Flow Direction Bi-Directional*

Body Taps 1/4” - 18 NPT

*Reverse flow by changing pilot connections and reversing spring case.

Table 1 Table 2

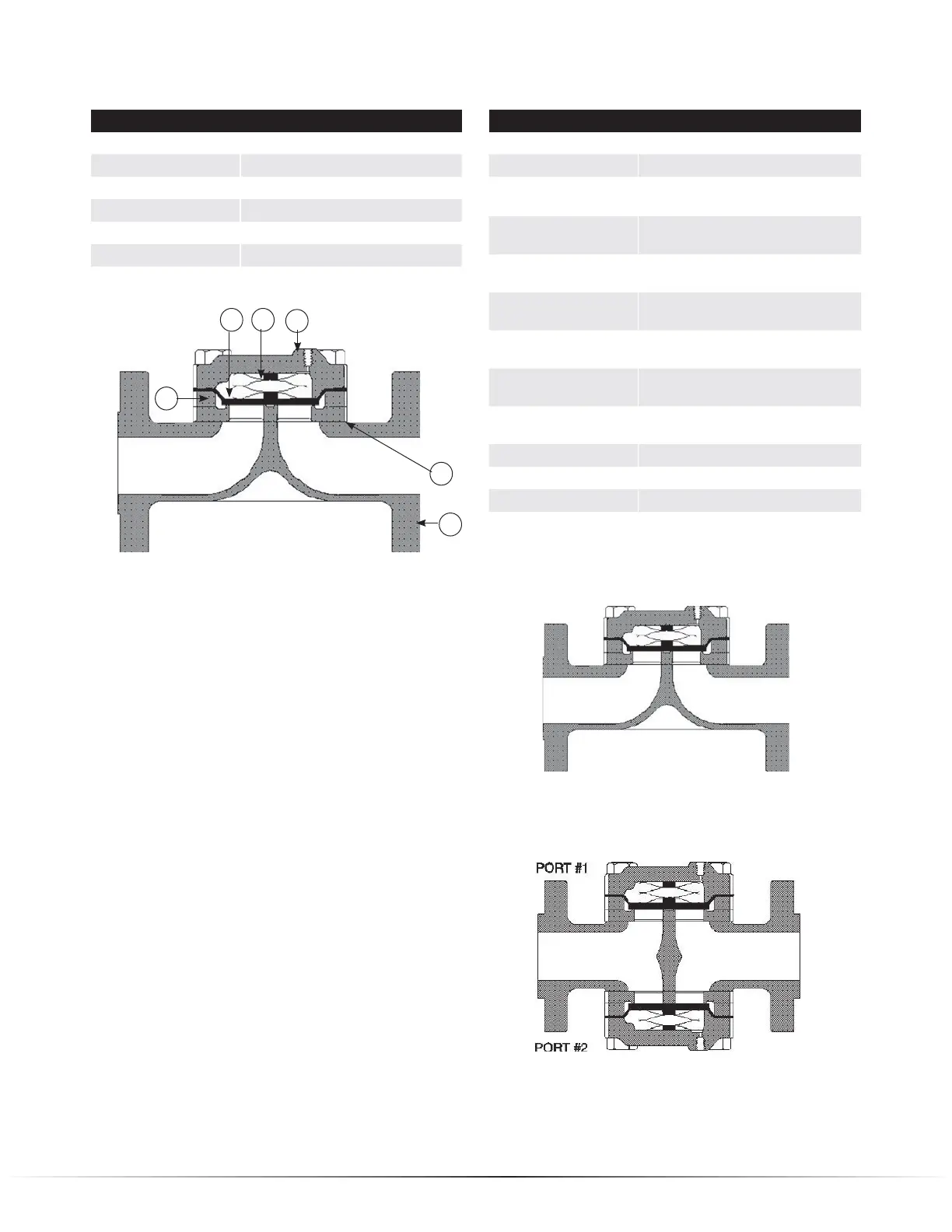

Figure 1

The throttle plate (2) supports the diaphragm and provides

a machined surface that the diaphragm seals against for

bubble tight shutoff. Restricted capacity plates of 35%, 50%,

and 75% are available.

The spacer (3) creates a space between the throttle plate

and the diaphragm which forms a flow path inside the valve.

The fabric-reinforced diaphragm (4) is the main working

part of the Flowgrid

®

valve. The diaphragm functions as both

an actuator and the valve throttling element.

It is designed to provide stability, rangeability, and fast

response without stretching. It will not “take a set” and is

thick for durability and wear resistance.

The main spring (5) provides high frequency response,

proportional action for stability and a consistent minimum

differential regardless of temperature. It also provides a

positive closing force, which is important in monitor regulation

application.

The spring case (6) is shaped to retain the main spring. It

provides a low volume cavity where loading pressure from the

pilot system is placed on top of the diaphragm to control flow

through the regulator.

3

1

4

2

5

6

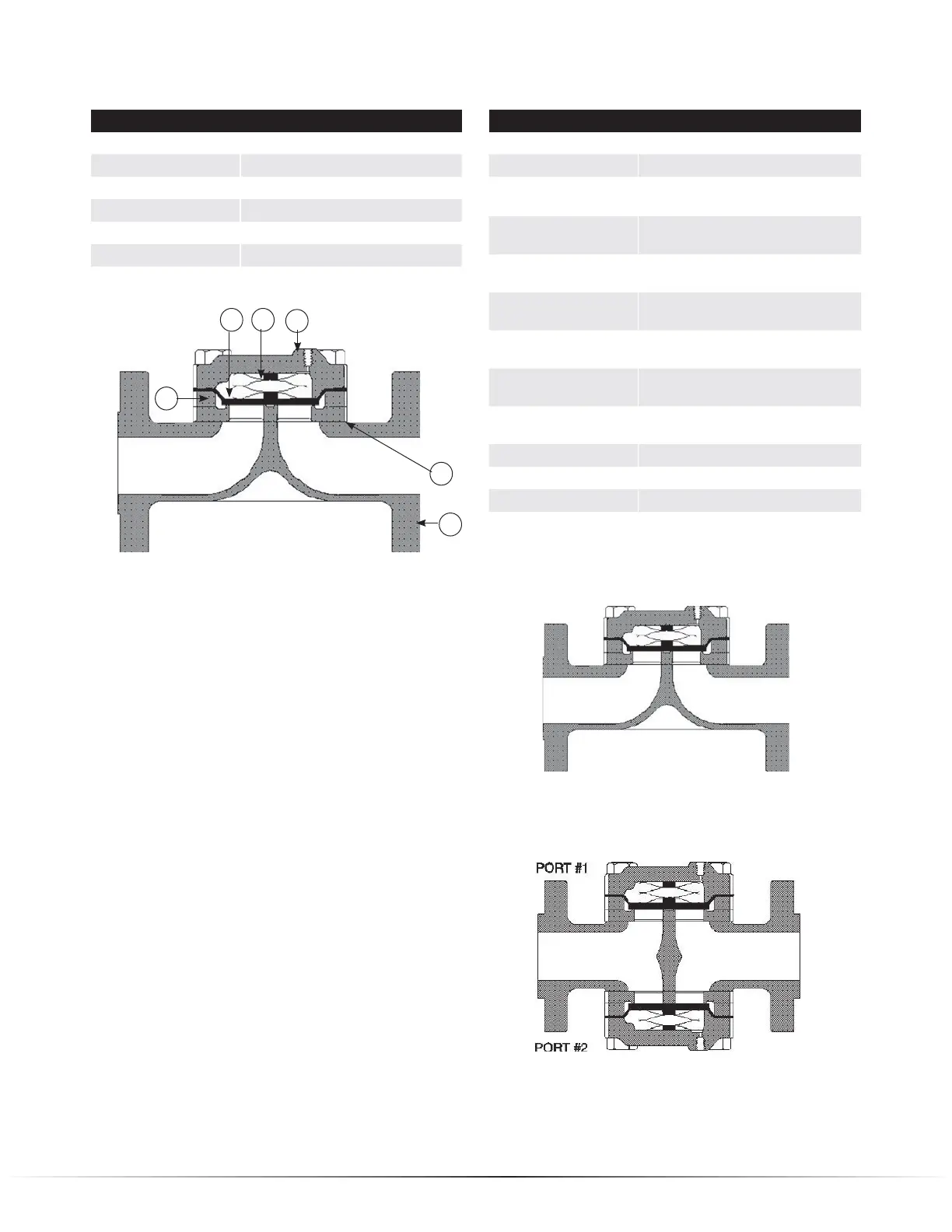

Figure 2

Figure 3

Loading...

Loading...