Flowgrid Regulator | 5

A back pressure regulator or relief valve controls upstream

pressure instead of downstream pressure. The control action

in the pilot is the reverse of a pilot for a pressure reducing valve

(increasing pressure in the sense chamber opens the pilot

valve). At no flow, when the inlet pressure is less than the set

point of the pilot regulator, the pilot is closed and full inlet pres-

sure loads the spring case through the pilot loading connection.

In this condition, the diaphragm is closed tightly against the

throttle plate. The pressure differential across the outlet half of

the diaphragm adds to the spring force in closing the Flowgrid

®

valve (Refer to figure 6).

As inlet pressure increases above the set point of the pilot

regulator, it will open and start bleeding pressure out of the

spring case faster than it can enter through the restrictor.

Reducing the pressure above the diaphragm allows inlet

pressure to progressively lift the throttling element off the throttle

plate opening the valve and satisfying the demand for flow in the

upstream system (Refer to Figure 7).

When upstream pressure decreases, causing the pilot regulator

to close, pilot supply pressure continues to pass through the

restrictor until the control pressure equals the inlet pressure.

The spring force, plus the pressure differential across the outlet

half of the throttling element closes the diaphragm against the

throttle plate, shutting off the flow (Refer to Figure 6).

Adjustment of the restrictor affects the response rate, stability,

and sensitivity of the regulator. Smaller restrictor openings result

in higher gain (sensitivity) and slower closing speeds. Larger

openings result in lower gain (greater proportional band), greater

stability and faster closing speeds.

Hydrostatic Testing

All Flowgrid

®

valves are hydrostatically tested at the factory

prior to shipment according to ISA-S75.19-1989 and

MSS-SP-61 standards. If it is necessary to retest the valve,

follow one of the procedures listed below to prevent damage

to the diaphragm.

OPTION 1

1. Disconnect and remove all control line(s) and the pilot

from the Flowgrid

®

Valve.

2. Loosen main spring case nuts in a crisscross pattern.

The main spring will lift the spring case as the nuts are

removed.

3. Remove main spring and diaphragm from valve.

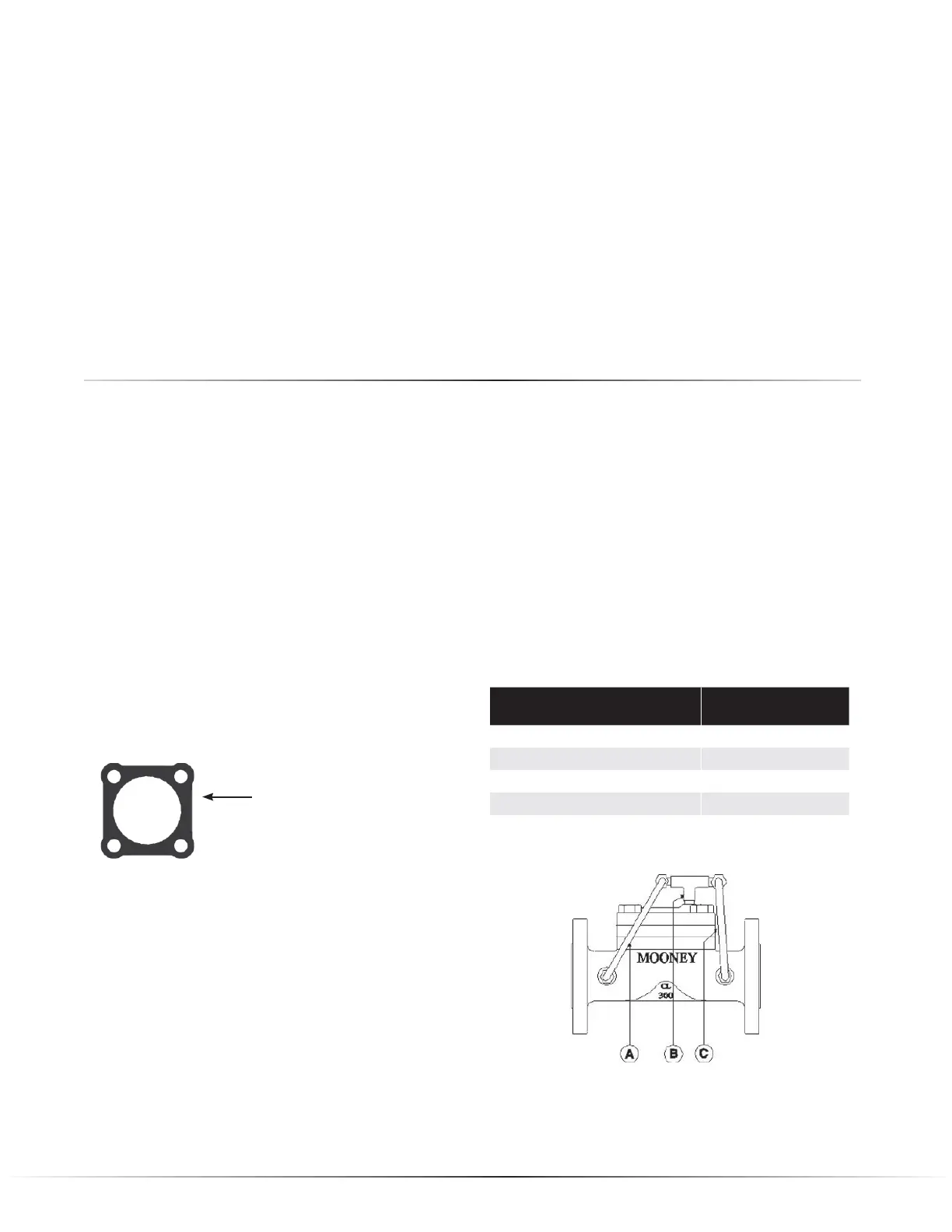

FOR ALL 1”, 2”, 4”, AND 6” (AND 10”-V6)

FLOWGRID

®

VALVES

4. Replace diaphragm with a used diaphragm that has

the thick padded area cut out leaving the outer sealing

surface (see below).

This area removed

FOR 3” AND 4” x 3” FLOWGRID

®

VALVES

4. Remove diaphragm but leave diaphragm O-ring in place.

Make sure O-ring is properly seated.

5. Reassemble spring case on Flowgrid

®

valve.

6. Tighten main bolts in increments using a crisscross

pattern. Torque bolting as indicated on valve nameplate

(or refer to Table 5 Page 14).

7. Plug spring case loading port, pilot inlet and outlet taps

on Flowgrid

®

valve.

8. Refer to Table 3 for the maximum hydrostatic test

pressure of each Flowgrid

®

valve.

9. After hydrostatic test is completed follow the

Disassembly, Cleaning, and Assembly procedures in the

MAINTENANCE section of this manual.

OPTION 2

1. Disconnect and remove all control line(s) and pilot from

the Flowgrid

®

valve.

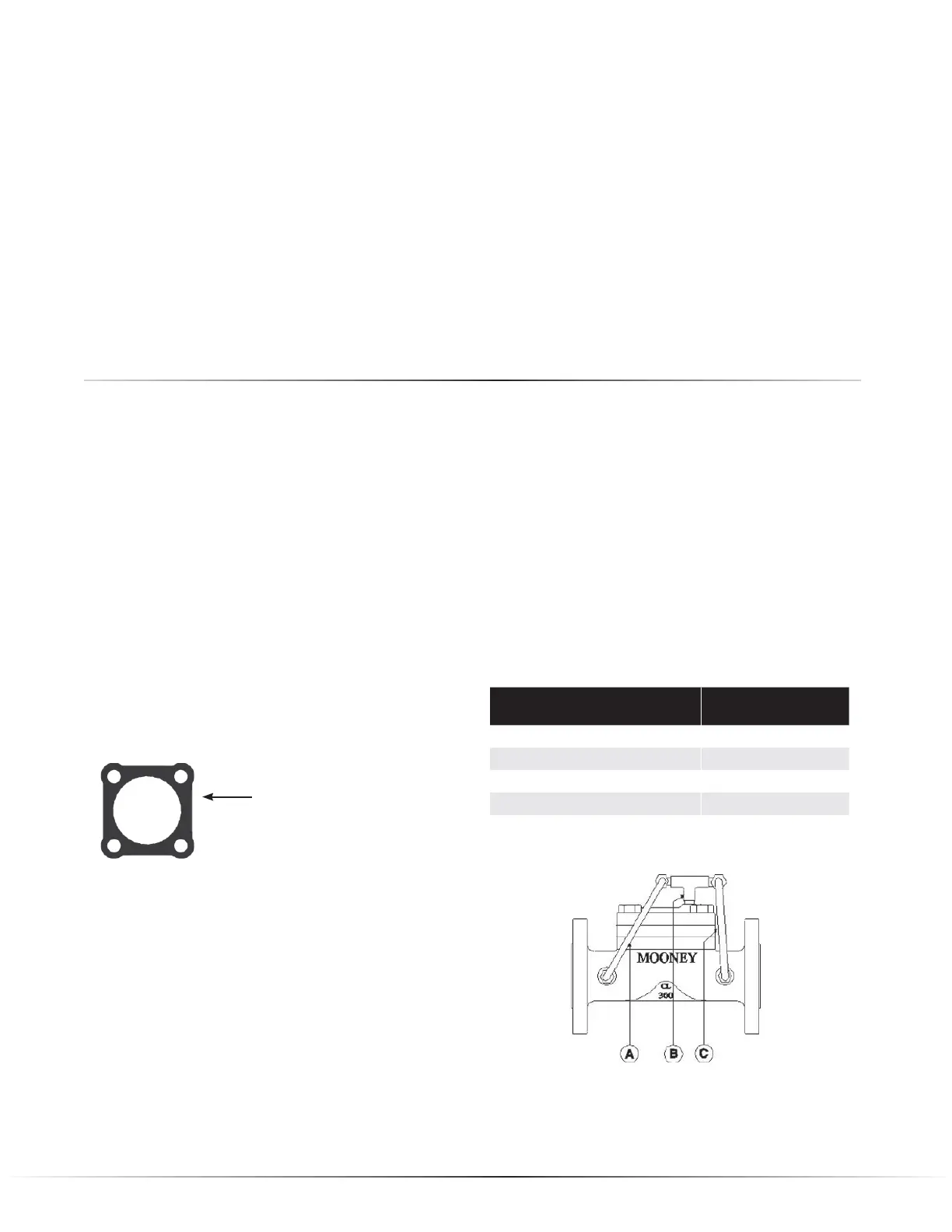

2. Pipe regulator with the inlet, outlet, and loading connec-

tions all common so that pressure is equalized in the

entire valve during the hydrostatic test. See Figure 8.

3. Refer to Table 3 for Maximum hydrostatic test pressure of

each Flowgrid

®

valve.

4. After hydrostatic test is completed follow the

Disassembly, Cleaning, and Assembly procedures in the

MAINTENANCE section of this manual.

End Connection Maximum Hydrostatic

Test Pressure (psi)

Screwed & Socket Weld 2225

150# Flange & Flangeless 450

300# Flange & Flangeless 1125

600# Flange & Flangeless 2225

Flowgrid 250*** 375

Maximum Hydrostatic Test Pressures

** The Flowgrid

®

250 is a ductile iron construction.

Table 3

Figure 8

A. Inlet connection on valve body joined to “Tee”.

B. “Tee” connected to loading connection on spring case.

C. Outlet of “Tee” connected to outlet connection on valve

Loading...

Loading...