REGULAR INSPECTION B-13

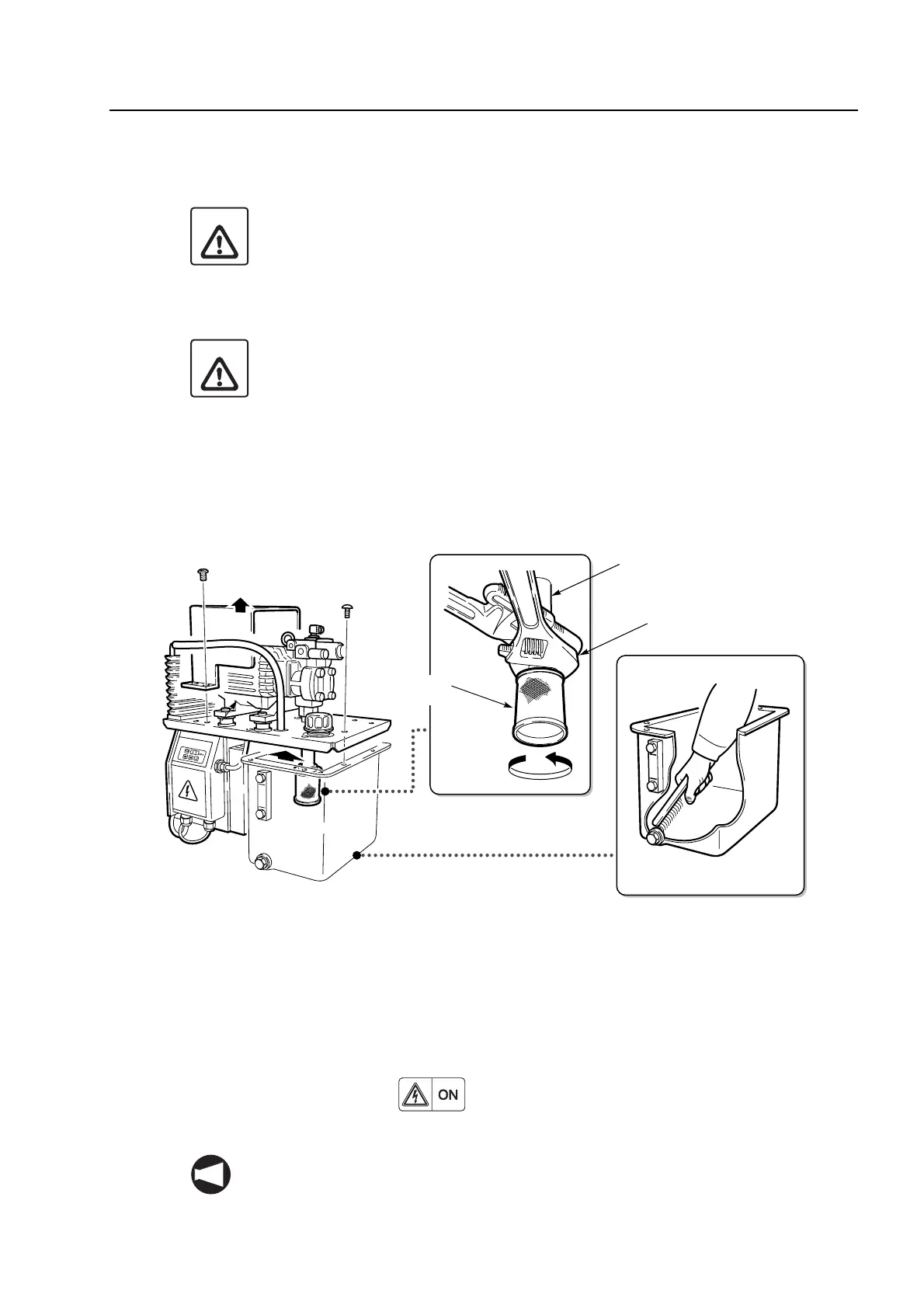

6) Clean the suction strainer using the following procedure:

a) Remove the suction strainer.

Clamp the suction pipe with a pipe wrench and turn the suction strainer to the left with a

monkey wrench. If the suction strainer is turned without clamping the suction pipe, the

suction pipe will turn with it, causing an oil leak.

b) Clean the suction strainer with kerosene.

c) Dry the suction strainer using compressed air.

Protective glasses must be worn to prevent eye damage form dust or foreign matter

(those who are wearing glasses included).

d) Apply sealing tape to the threaded section of the suction pipe and reattach the suction

strainer.

7) Clean the inside of the tank with kerosene.

8) Remove foreign matter form around the drain plug using a brush.

9) Remount the tank upper plate.

10) Remount the hydraulic unit on the machine.

11) Connect the piping.

12) Remove the fill port cap.

13) Supply oil while checking the oil level gage.

14) Turn ON the main power.

15) Confirm pump pressure and suction noise are normal.

If the suction sound is louder than prior to oil replacement, check the oil level again.

CAUTION

CAUTION

Suction strainer

Suction pipe

Monkey wrench

× 8

× 4

NOTE

Loading...

Loading...