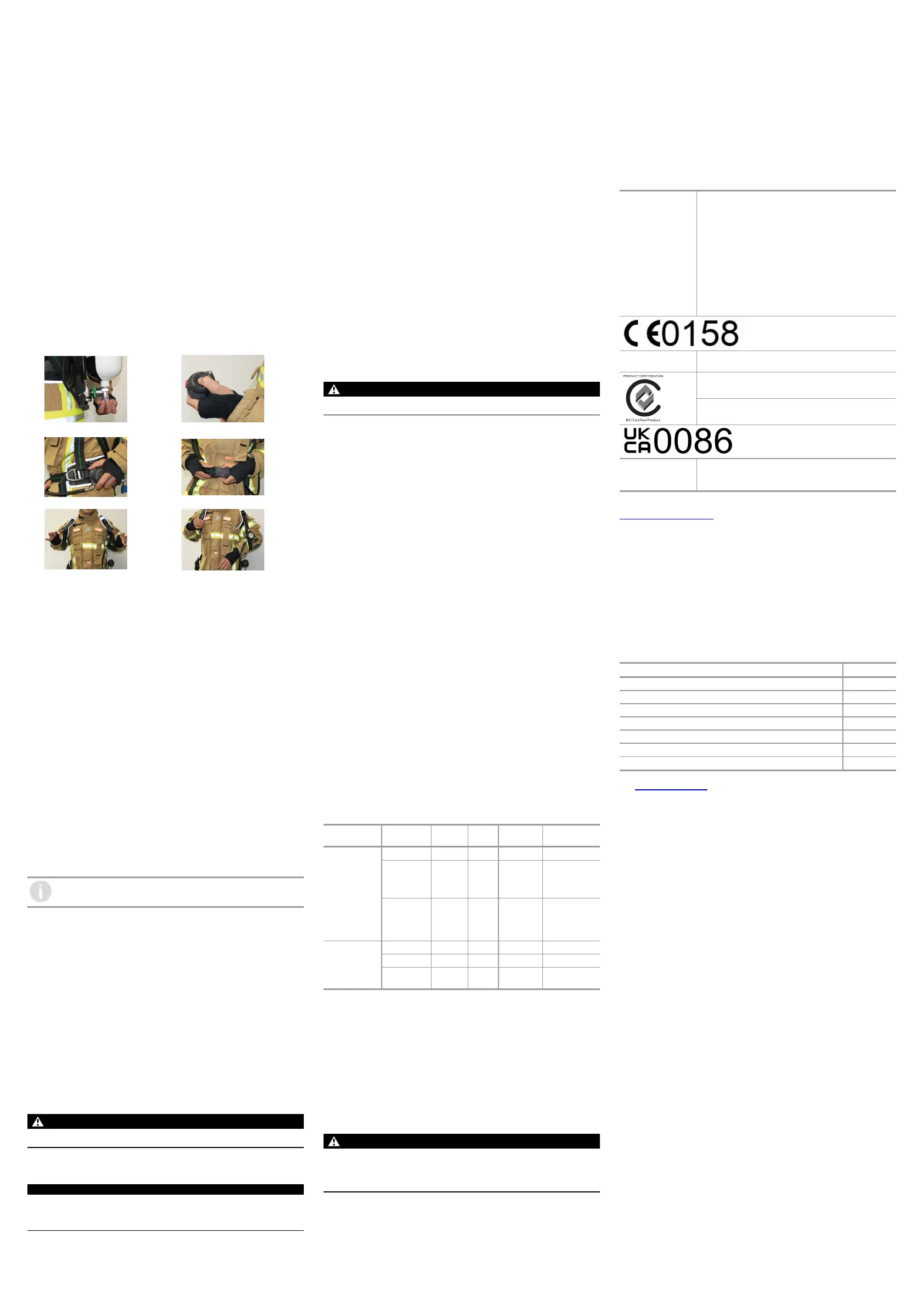

2. Bend forward slightly; resting the carrier on the back. Pull down shoulder

straps to pre-tighten SCBA.

3. Fasten the hip belt and pull forward on the waist strap pull tabs to tighten

for a snug fit (advanced harness). For basic harness, pull sidewards on

the waist strap pull tabs to tighten.

a. Most of the SCBA weight should be carried on the hip.

4. Stand up straight. Pull down on the shoulder strap pull tabs to tighten

straps. Adjust the hip belt if necessary. Fasten chest strap (if used).

5. Grab the LGDV and push the side buttons to release the LGDV from the

LGDV retainer.

6. Make sure the LGDV is switched off before opening the cylinder valve(s).

7. Reach behind and fully open the cylinder valve(s).

3.5 During Use

Periodically check the pressure indicated on a chest mounted pressure indicator

during use.

When the needle on the pressure indicator reaches the red zone on the gauge

face, the primary low pressure warning device alarms.

The primary low pressure warning device indicates when cylinder pressure drops

below these approximate values:

• 55bar ±5bar for a 300bar system

Immediately return to a non-hazardous atmosphere if:

• SCBA free-flows (provides air when not inhaling).

• Low pressure warning device sounds.

• When the pressure warning device indicates 35% cylinder pressure,

immediately return to a non-hazardous atmosphere.

• If the air flow in the SCBA is reduced: Immediately keep purge pressed.

Immediately return to a non-hazardous atmosphere.

3.6 After Use

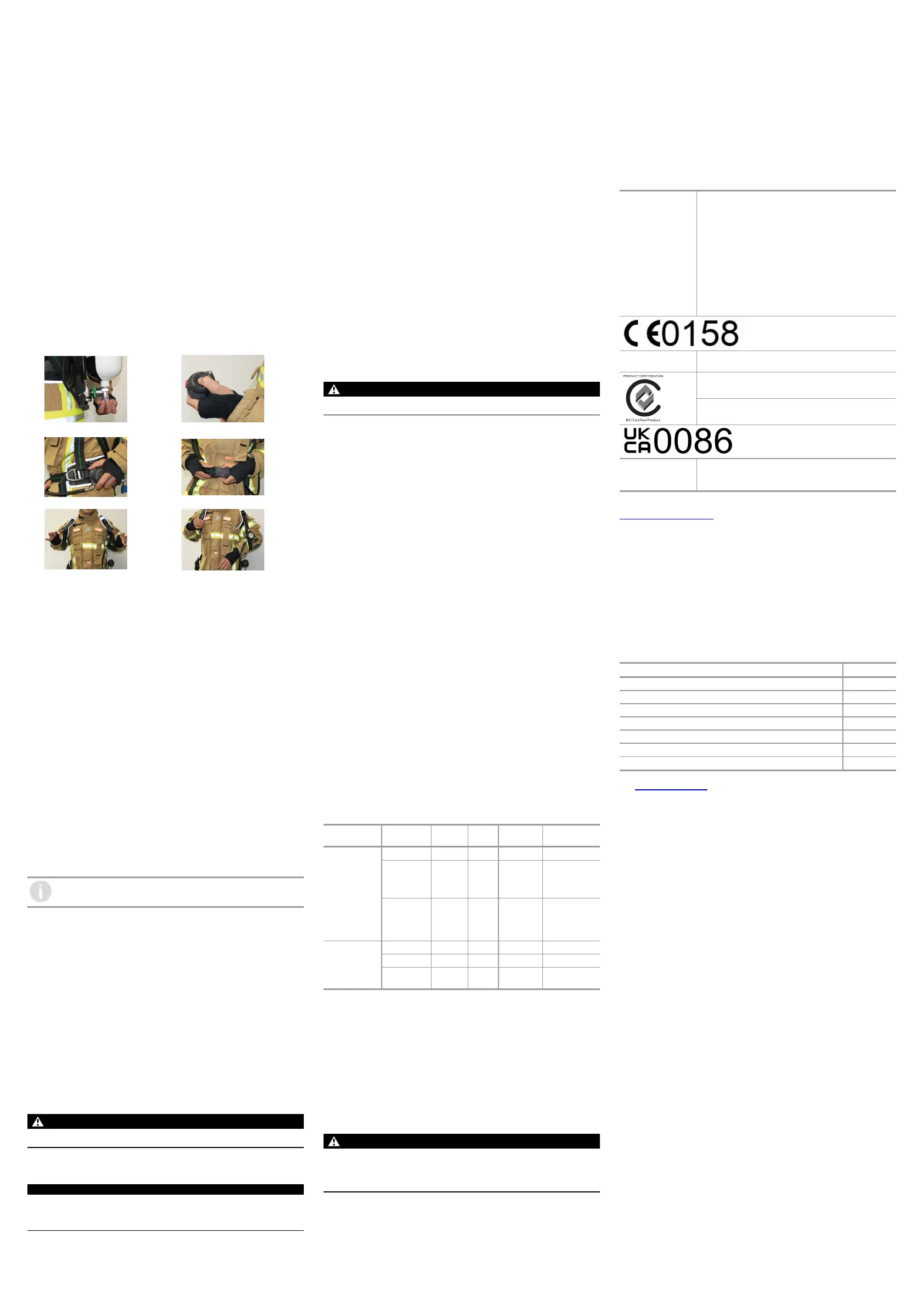

1. 2.

3. 4.

5. 6.

1. Close the cylinder valve(s) fully.

2. Press the purge button to release system pressure.

3. Stow the LGDV in the LGDV retainer when it is not in use.

4. To remove the carrier and harness, press both buttons of the hip belt

buckle.

5. Disconnect the chest strap buckle by pressing both buttons at the same

time (if used). To loosen the shoulder straps, lift the pull tabs and push

them out and away from the body.

6. Slip the left arm out of the shoulder strap first, then remove the harness.

3.7 Cylinder Fitting and Removing

Removing the Cylinder(s)

1. Lay the backplate of the SCBA horizontal with cylinder(s) facing up.

2. Ensure there is no pressure in the system before replacing a cylinder.

a. Close the cylinder valve(s).

b. Press the purge button of the LGDV until air no longer

discharges.

3. Hinge down the securing bracket.

4. Hinge up cylinder buckle at cylinder strap and thus loosen the strap.

5. Disconnect the cylinder(s):

Threaded connection:

• Unthread handwheel from cylinder valve assembly and/or T-piece.

alphaCLICK2 connection:

• Turn the handwheel on the coupling side first clockwise, when the stop is

reached, push downwards in the direction of the pressure reducer.

• The cylinder adapter releases from the alphaCLICK2coupling.

When exchanging compressed air cylinders of the same diameter, only

the cylinder buckle needs to be opened.

6. Lift cylinder(s) at the valve and pull out of cylinder strap.

7. Close high pressure connection cylinder valve(s) with protection cap (not

required for alphaCLICK2).

Attaching One Cylinder

1. Lay the backplate of the SCBA horizontal with cylinder side facing up.

2. Slide the fully charged cylinder into the carrier.

3. Open cylinder buckle on the cylinder strap eliminating any tension and

extend the strap using the slider (if necessary).

4. Push compressed air cylinder through the cylinder strap with the cylinder

valve toward the pressure reducer, so that it lies on the cylinder cradle.

Threaded connection:

○ Thread cylinder valve to the pressure reducer, if necessary, bring

the SCBA with valve up into a vertical position.

alphaCLICK2 connection:

○ Align the compressed air cylinder with the alphaCLICK2axially

to the coupling and fit on the alphaCLICK2 coupling.

○ Close the coupling by pushing together using a light force.

CAUTION!

Never push the coupling system together using excessive force.

Failure to follow this caution can result in minor or moderate injury.

5. Tighten cylinder strap by pulling the free end.

6. Check position of compressed air cylinder, retighten if necessary.

NOTICE

Damage can occur when using excessive force to close the cylinder buckle and

the SCBA might not be ready for use.

• Do not overtighten the cylinder strap.

7. Hinge cylinder buckle down until it catches.

If strap tension is too high during hinging of the cylinder buckle, re-adjust

the strap length at the cylinder buckle. If the strap tension is too low, re-

adjust the strap length at the cylinder buckle.

8. Hinge up the securing bracket until it catches.

9. Fasten end of the cylinder strap by moving the small slider.

10. Briefly open cylinder valve and check for escaping air, retighten if

necessary.

11. To check that the cylinder is secure, place one hand on the backplate and

grab the cylinder valve with the other hand. Try to pull the cylinder and

valve down and out away from the carrier. Make sure that the strap holds

the cylinder securely in the carrier.

NOTE: If the cylinder feels loose, check that the latch engages with the proper slot

on the strap. Ensure that the latch is fully tightened. Do not use the SCBA if the

cylinder is not held securely in the carrier.

12. Align the handwheel assembly to the cylinder valve.

Threaded connection:

○ Before installing the threaded handwheel, check that the O-ring

inside the handwheel coupling nut is present, clean and free of

damage. If the O-ring is damaged, it must be replaced before the

SCBA is used.

○ Thread the handwheel onto the cylinder threads. The handwheel

should be hand-tight (no tools).

alphaCLICK2 connection:

○ Before installing check that the male and female end of the

coupling are clean and free of damage. Ensure the adapter on

the cylinder valve is tight (torque 20 to 30Nm).

○ If necessary, thread the alphaCLICK2 cylinder adapter with a

specific torque of 20 to 30Nm into the cylinder valve.

○ Push the alphaCLICK2 connect coupling onto the cylinder valve

adapter until an audible snap is heard. The handgrip will rapidly

rotate approx. 45° counter clockwise indicating that the valve is

connected to the pressure regulator.

○ Grab the handwheel firmly and pull on it to ensure the handwheel

is fully attached.

Attaching Two Cylinders

CAUTION!

Never push the coupling system together using excessive force.

Failure to follow this caution can result in minor or moderate injury.

1. Open cylinder buckle on the cylinder strap eliminating any tension and

extend the strap using the sliders (if necessary).

2. Push one compressed air cylinder through the cylinder strap with the

cylinder valve toward the T-piece, so that it lies on one of the outer

supports.

3. Thread the cylinder valve onto the T-piece.

4. Push a second compressed air cylinder through the cylinder strap so that

the cylinder valve points to the T-piece and lies on the outer supports.

5. Thread the second cylinder valve onto the T-piece.

○ Before installing the threaded handwheels, check that the O-

rings inside the handwheel coupling nut on the pressure reducer

and the T-piece are present, clean and free of damage. If the O-

rings are damaged, they must be replaced before the SCBA is

used.

○ Thread the handwheels onto the cylinder threads and T-piece.

The handwheels should be hand-tight (no tools).

6. Align the compressed air cylinders with the T-piece and retighten

handwheels if necessary.

7. Tighten cylinder strap by pulling the free end.

8. Check position of compressed air cylinders, retighten if necessary.

9. Hinge cylinder buckle down until it catches.

If strap tension is too high during hinging of the cylinder buckle, re-adjust

the strap length at the cylinder buckle. If the strap tension is too low, re-

adjust the strap length at the cylinder buckle.

10. Hinge up the securing bracket until it catches.

11. Fasten end of the cylinder strap by moving the small slider.

12. Briefly open cylinder valves and check for escaping air, retighten if

necessary.

13. To check that the cylinders are secure, place one hand on the backplate

and grab the cylinder valves with the other hand. Try to pull the cylinders

and valves down and out away from the carrier. Make sure that the strap

holds the cylinders securely in the carrier.

NOTE: If the cylinders feel loose, check that the latch engages with the proper slot

on the strap. Ensure that the latch is fully tightened. Do not use the SCBA if the

cylinders are not held securely in the carrier.

4 Maintenance and Care of the SCBA

4.1 Maintenance Intervals

Component Work to be

performed

Before

use

After

use

Annually Every

120months*

M1

Cleaning X X

Visual,

function and

tightness

check

X X X

Overhaul

X

or after

600hours of

active use**

alphaCLICK2

coupling

Cleaning X

Lubricate X***

Check by

user

X

*

Applicable national regulations must be observed (e.g. GFPA German

Fire Protection Association directive 0840, attachment 2).

**

For SCBA apparatus that are frequently used, MSA recommends a

complete overhaul after approx. 600 hours.

For example, this corresponds to 1200 applications with a duration of

30minutes.

***

Lubricate alphaCLICK2 coupling every 500 coupling cycles or when

necessary.

See “Maintenance alphaCLICK2 high pressure coupling”.

5 Storage

WARNING!

DO NOT drop the cylinder or bump the valve knob. An unsecured cylinder can

become an airborne projectile under its own pressure if the valve is opened even

slightly.

Failure to follow this warning can result in serious personal injury or death.

• Do not store the SCBA or spare cylinders within or near an area where the

SCBA can or might be exposed to any substances and ambient conditions

that will or might attack any part of the SCBA, causing the SCBA to not

perform as designed and approved.

• Prior to storing the SCBA in a jumpseat, ensure there is no interference

between the SCBA and the seat. Ensure the SCBA and cylinder can be

removed easily without damaging the components.

• Do not store the SCBA for extended periods with the batteries installed in

the electronic components (if available) if the SCBA is not intended for

service. If the SCBA is in service, ensure that the batteries in the

electronic components (if available) have an adequate charge.

• Do not store the SCBA with an empty or partially filled cylinder. Always

install a fully-charged cylinder so that the SCBA is ready for use.

• Ensure the entire SCBA is clean and dry.

• Ensure the SCBA harness and full face mask head harness adjustment

straps are fully extended. Place the complete SCBA in the storage case or

suitable storage location so it can be easily reached for emergency use.

• For prolonged storage of the SCBA, remove the batteries from all

electronic components (if available) and housings to prevent battery

corrosion. Store the units in a cool, dry place.

6 Certification

6.1 Complete Device

Approvals

The compressed air breathing apparatus conforms to the

Regulation (EU) 2016/425, Directive 2014/34/EU and

PPE Regulation (EU) 2016/425 as retained in UK Law

and amended. It is a self-contained open circuit

compressed air breathing apparatus in accordance with

harmonized/designated standard EN 137:2006, type 2,

for the extended temperature range from -40 °C to +60

°C.

The function of the electronic components were not

assessed for the certification in accordance with

Regulation(EU)2016/425, because even in case of a

complete failure of all electronic components, the

respiratory protection provided by MSA M1 remains

unchanged.

Notified body

DEKRA Testing and Certification GmbH, Dinnendahlstr.

9, 44809Bochum, Germany

AS/NZS 1716:2012 Lic: BMP No 713832

Australian/New Zealand Standards

BSI Group ANZ Pty Ltd, Suite 2, Level 7, 15 Talavera

Road, MacquariePark, NSW 2113

Approved body for

product certification

and site surveillance

BSI Assurance UK Ltd, Kitemark Court, Davy Avenue,

Knowlhill, Milton Keynes, MK5 8PP, United Kingdom

The Declaration of Conformity can be found under the following link:

https://MSAsafety.com/DoC.

6.2 Marking

For ATEX marking for use in potentially explosive atmospheres see M1 Modular

SCBA System operating manual. For CBRN application and component selection

see M1 Modular SCBA System operating manual. Full face mask: see operating

manual for Full Face Mask and Mask/ Helmet Combination. The ATEX class of any

other equipment used together with this device has to be regarded as well. The

lowest class sets the limit.

7 Ordering Information

For this product, order numbers have been replaced by an ATO (Assemble To

Order) code. See M1 Modular SCBA System operating manual.

Manual Part Number

Operating Manual Modular M1 SCBA System 10195758

Operating Manual M1 LGDV 10190261

Operating Manual G1 Facepiece 10161150

Operating Manual alphaBELT 10156929

Operating ManualSingleLine SCOUT 10186539

Operating Manual 3S and Ultra Elite full face masks 10126346

Cleaning and Disinfection Guidelines M1 Modular SCBA System 10203757

See www.MSAsafety.com.

Loading...

Loading...