318 Load Unit

92

Routine Maintenance Overview Checklist

Maintenance

B. Tighten to 5% of the torque recorded on the identification plate.

Hex nut—Tighten the nut to 5% of the final torque shown on the

identification plate.

Preloader collar—Tighten the jackbolts or setscrews to 5% of the

final torque shown on the identification plate.

C. Rotate the indicator to see if the TIR is still 0.038 mm (0.0015 in) or

less. If not, loosen the nut or preloader collar and return to Step 4.

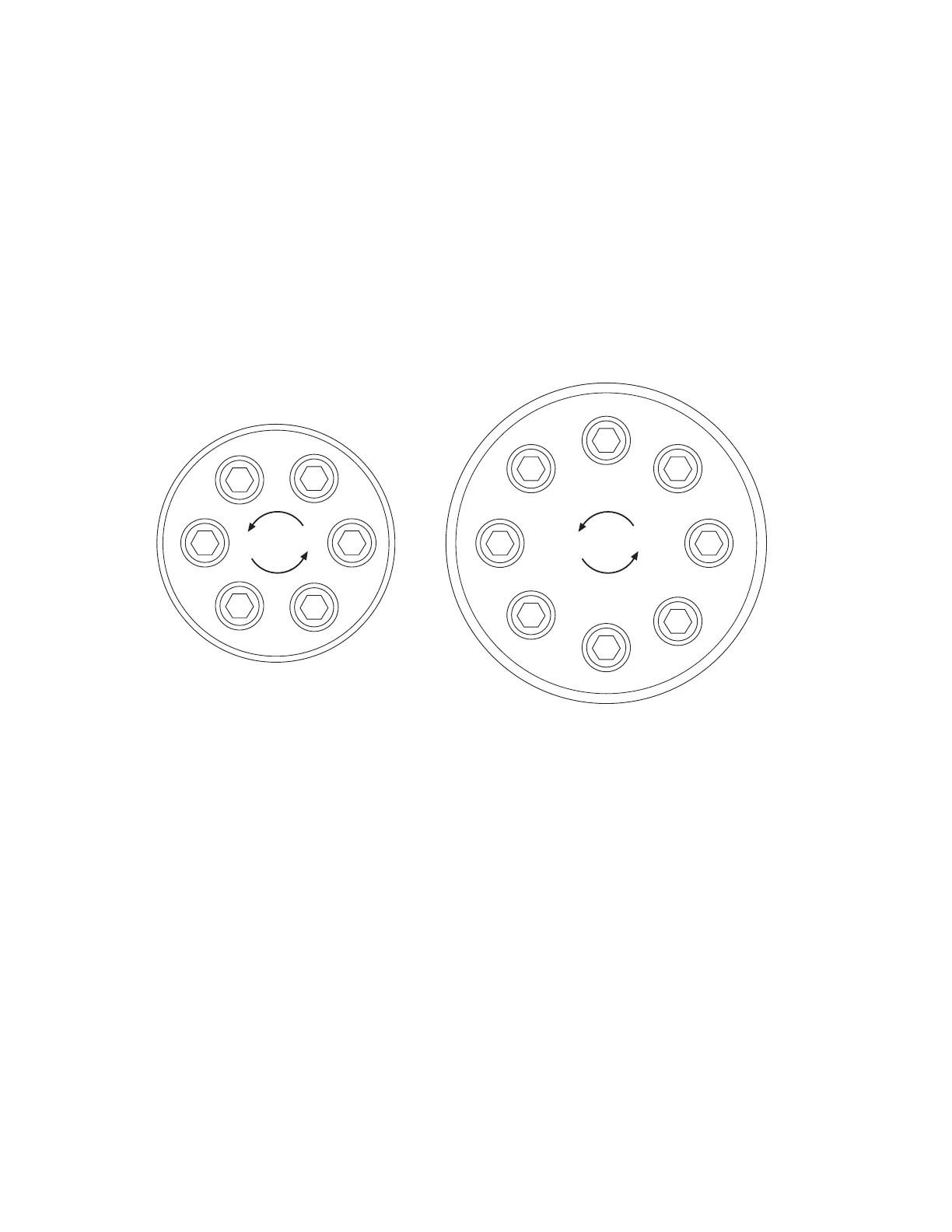

(Loosen the preloader collar following the sequence shown below.)

D. Repeat Steps B and C to tighten the force transducer for the following

torque progression: 50%, 75%, and 100%.

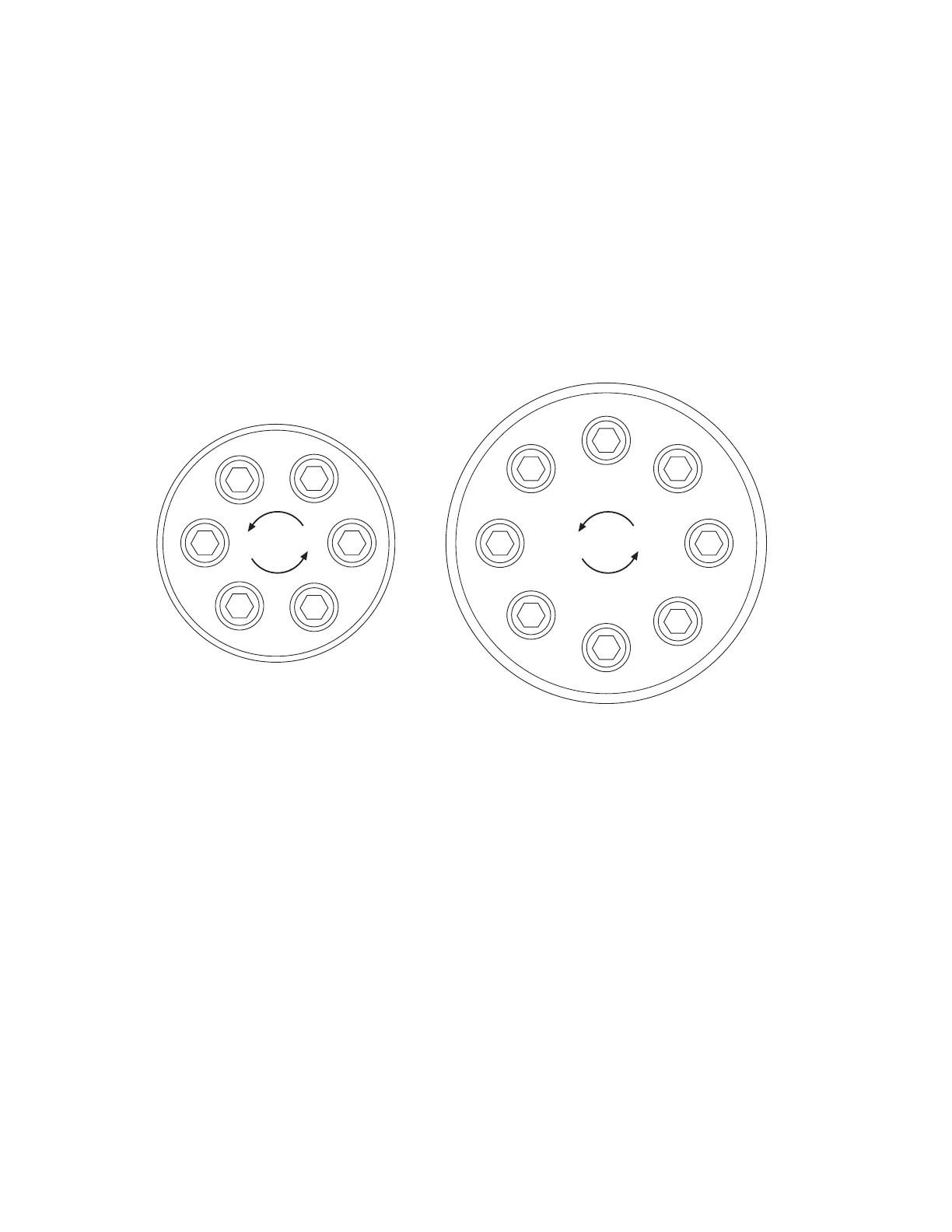

Bolt Torque Sequence

E. Preloader collar only—For uniform tightness, retorque the jackbolts

or setscrews to 100% of the final torque shown on the identification

plate.

6. Finish the procedure.

In this step, you complete the force transducer alignment procedure.

A. Remove the dial indicator.

B. If you reduced pressure at the hydraulic power unit, restore full

hydraulic pressure.

Loading...

Loading...