MUELLER

®

B-101

TM

and B-100

TM

Drilling and Tapping Machines

Operating Instructions

8

6. Continue tapping operation until

tapping line on boring bar is flush

with the top of the feed sleeve part

of the cap. (J.)

When tapping asbestos-cement with

one piece Cem-Res

®

combined drills

and taps, it is advisable to exceed

the tapping line enough to allow

corporation stops to be inserted

with only one to three threads

exposed. The exact amount may be

determined by making a “shop-tap”

ahead of time. (Use 50 to 80 foot

pounds of torque to tighten valve

into main after removal of machine.)

Remove The Tool From Main

1. If hand ratchet was used to

make tap, reverse ratchet handle

by adjusting for counter-clockwise

rotation. Rotate the ratchet handle

counter-clockwise carefully and

back out the tool. DO NOT force the

tool when removing it, as this may

cause breakage of the tap teeth.

CAUTION: When this machine

is under pressure, control the

piston action of the boring bar to

prevent bodily injury or damage

to machine.

2. If power operation has been

used to make the tap, reverse the

motor and back out the tool. Control

upward movement of the boring bar

by maintaining a firm hold on the

gear case and motor as stated in

previous caution note.

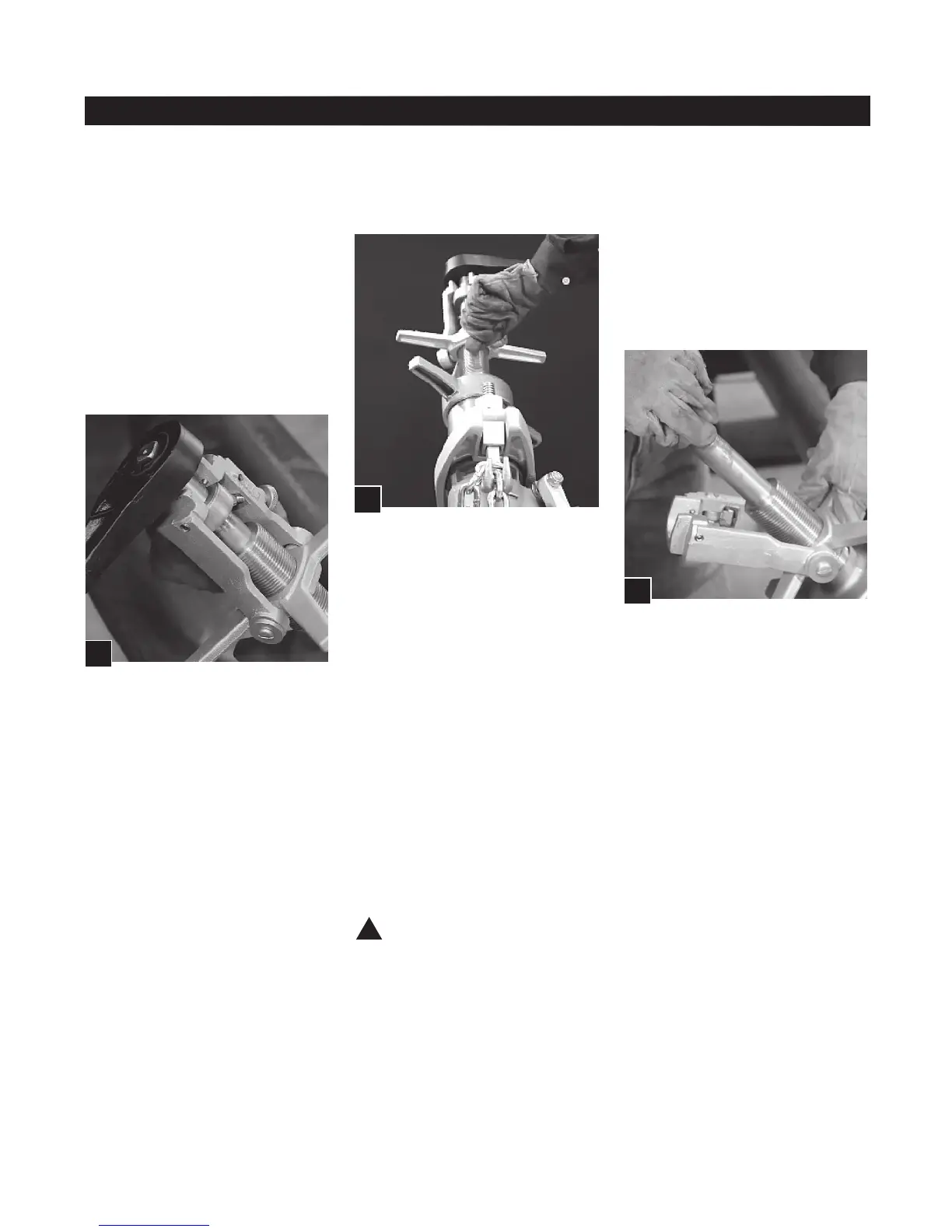

5. Start motor and rotate feed nut

clockwise by hand to engage tap

part of tool into main. Continue to

rotate feed nut until tap is securely

started into the main and feed yoke

is no longer needed to take thrust

of boring bar. At this point, the feed

yoke may be removed from contact

with thrust collar (on the B-101,

turn the operating screw counter-

clockwise to unlock the pivot arm

and remove the feed yoke) allowing

the boring bar to move downward

and the tool to feed itself. (I.)

NOTE: Feed yoke should remain

in contact with the boring bar

thrust collar and follow the thrust

collar down when machine is

being used on high pressure

mains, thin wall steel pipe or

asbestos-cement pipe. DO NOT

overfeed faster than the tap

is cutting as this will strip the

threads being tapped in the main.

During the tapping operation with

either the B-101 or B-100 machines,

extra precaution is required

because the additional weight of

the power operator tends to cause

overfeeding of the tap resulting

in stripped threads. This is more

serious when tapping asbestos-

cement pipe dry.

IMPORTANT: We recommend

only hand operation of the B-101

or B-100 machines during the

tapping operation of asbestos-

cement pipe which is not under

pressure.

3. When the tap is entirely free from

the pipe, withdraw the boring bar

to the uppermost position again

applying some downward force to

prevent uncontrolled withdrawal of

the boring bar.

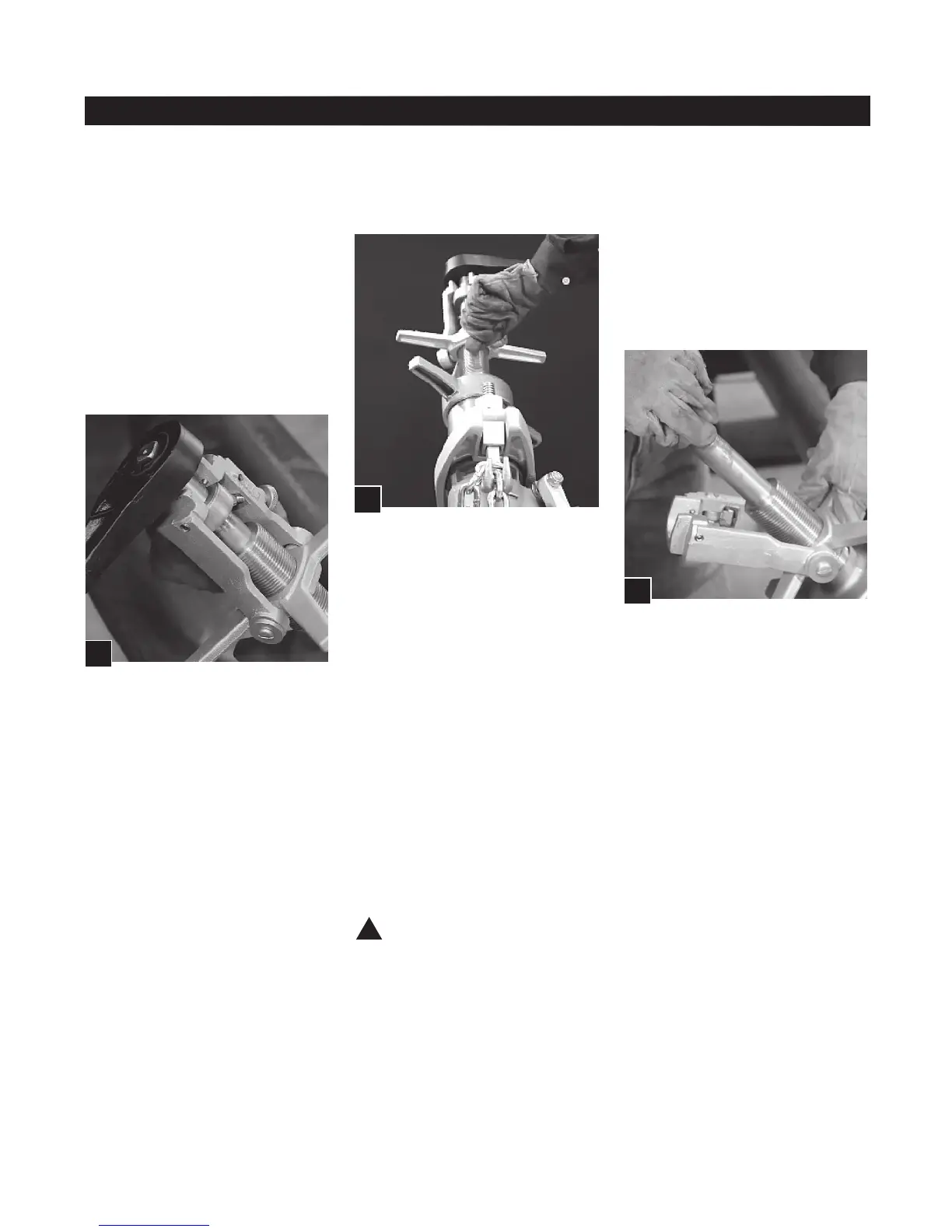

If the pressure in the main is greater

than 90psi, a power clevis (H-10802)

may be used to control the upward

movement of the boring bar. (K.)

A power clevis is used as follows

to allow the upward movement of

the boring bar to be done under

controlled conditions. If a power

drive unit has been used to tap the

main, the power unit is removed and

a hand ratchet is used to replace

the gear case.

a). Hook the bent end of the

power clevis over the feed cap

handles.

b). With the ratchet handle in

place on the boring bar, bring the

center point of the control screw

down into contact with the center

hole in end of boring bar.

c). Rotate the ratchet handle

counter-clockwise and the

control screw on the power clevis

at the same rate. As the tap backs

out of the pipe, the power clevis

controls the upward movement.

d). When the tap threads are

out of the main, rotation of the

ratchet handle can stop while the

control screw is rotated to raise

the boring bar to its uppermost

position.

I.

J.

!

K.

Loading...

Loading...