MUELLER

®

B-101

TM

and B-100

TM

Drilling and Tapping Machines

Operating Instructions

9

Attach Stop Or Plug To Boring

Bar

IMPORTANT – Check to be sure

the stop to be installed is fully

closed.

1. Screw together the proper screw

plug and the stop or plug to be

inserted. Be sure these threads

screw together freely without

binding.

When using an E-Z Release screw

plug, also lubricate and check the

acme threads between the two parts

of the screw plug. (N.)

2. Slide knockout pin in boring bar

socket to its outward position using

pin extending through bottom of

boring bar bearing as a handle.

3. Insert shank end of screw plug

into boring bar socket aligning

driving pins on tool with slots in end

of boring bar and firmly push screw

plug and stop assembly to its rear

most position. (O.)

4. Tighten tool-retaining screw in

boring bar using small socket end

of chain hook nut and tool retaining

screw wrench.

5. Push the cap down on the boring

bar as far as possible.

6. Coat the inlet threads of the

corporation stop or with non-

hardening pipe thread sealant or

Teflon

®

tape (P.)

4. With the boring bar in its

uppermost position, close flop valve

by loosening handle screw (if lever

handle was locked open) and raising

upward on lever handle.

If machine is being operated on low

pressure, it is advisable to retain

flop valve in closed position by use

of handle screw on lever handle.

The handle screw in lever handle is

tightened against wedge on side of

body.

5. With flop valve closed, pull

bypass valve to “relieve” position.

This relieves the pressure above

the flop valve and allows the line

pressure to keep the flop valve

closed, which is assisted by handle

screw if it is used. (L.)

6. Retain boring bar in its uppermost

position, while feed sleeve and cap

and boring bar assembly is removed

from cylinder of machine.

7. Remove combined drill and tap

from boring bar by first loosening

the tool retaining screw with the

socket end of the chain hook nut

and tool retaining screw wrench, but

DO NOT remove screw.

8. Strike the head of the knockout

pin with a light blow to loosen the

combined drill (or shell cutter) and

tap. (M.)

9. Remove the combined drill and

tap from boring bar socket.

7. Replace feed sleeve and cap

and boring bar assembly onto the

cylinder of machine and tighten cap

securely so that a pressure tight

joint is formed.

Insert The Stop Or Plug

1. Hold boring bar assembly in

uppermost position. Push bypass

valve to “bypass” position.

2. Attach ratchet handle and set for

clockwise rotation.

3. Open flop valve by loosening

handle screw, If it was tightened,

and pushing lever handle all the

way down. Handle screw should be

engaged into socket on side of body

to retain flop valve in open position

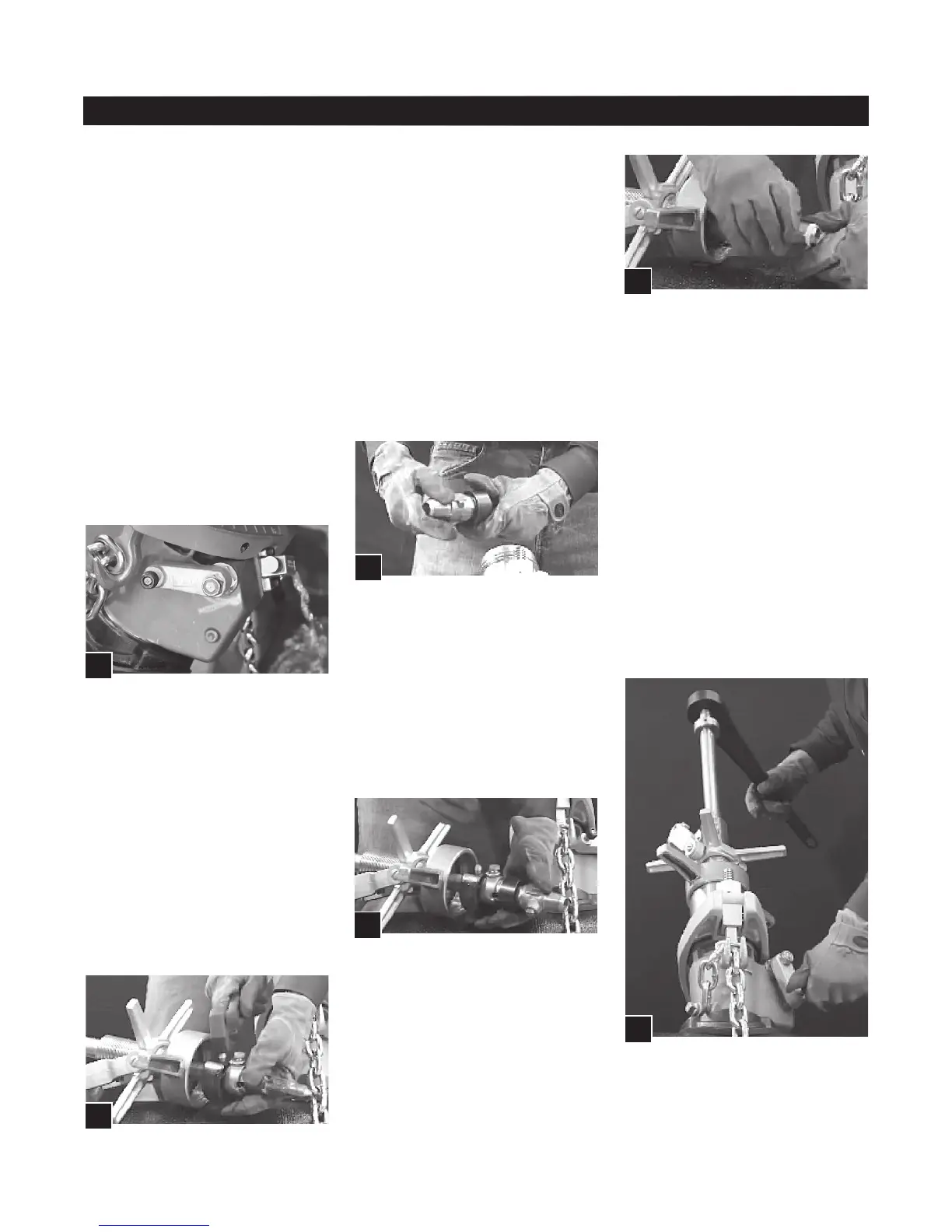

during this operation. (Q.)

4. Push the boring bar down until

the inlet threads of the stop or plug

contact the threads in the pipe. For

pressure greater than 90psi use a

power clevis to force the boring bar

down. See Instructions “F-3”.

L.

M.

N.

O.

P.

O.

Loading...

Loading...