MUELLER

®

Centurion

®

Series Fire Hydrant

Adding an Extension

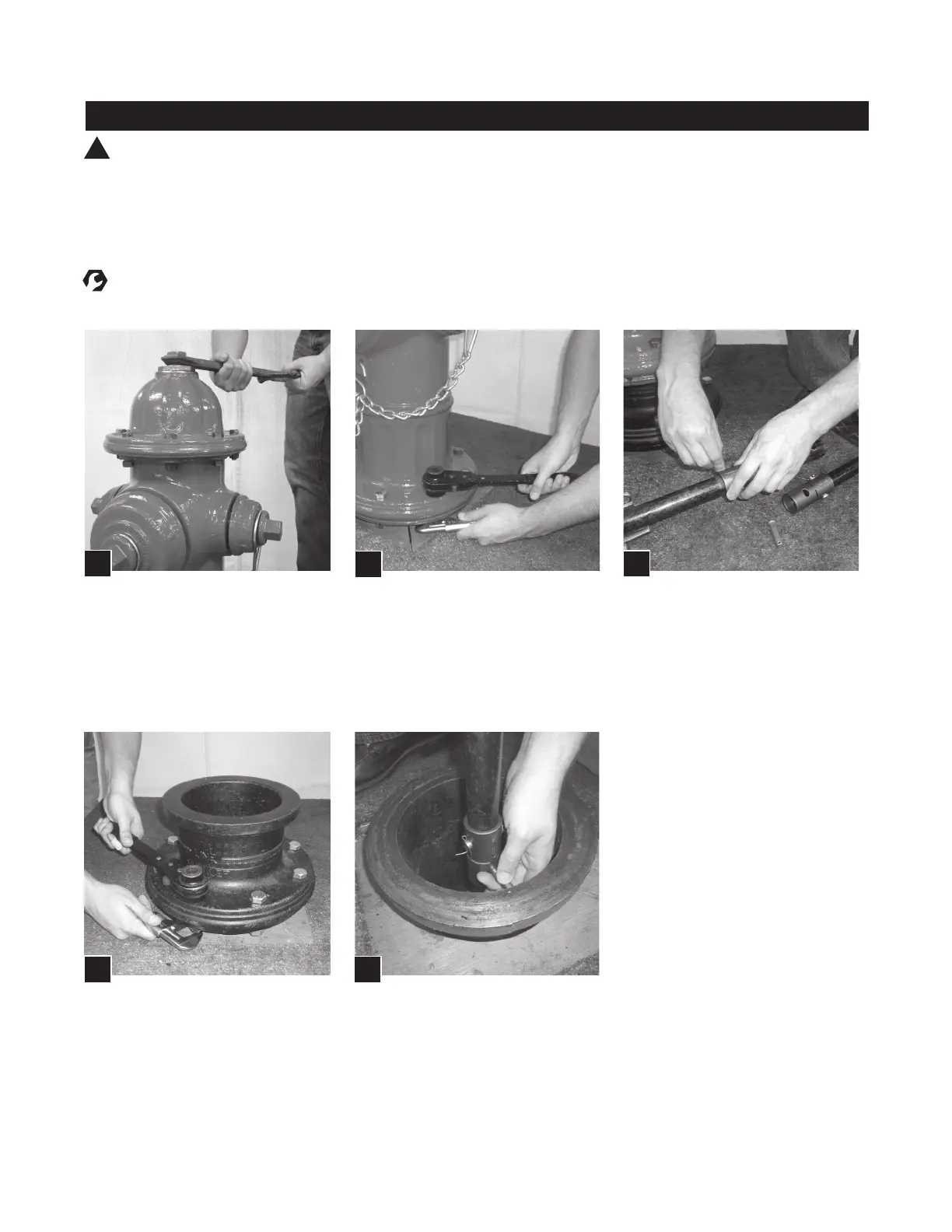

4.

Attach Extension Barrel to Lower

Barrel with solid Flange halves

(without groove) and Bolts, being

sure O-ring is in place.

WARNING: Before removing any bolt(s) holding the Hydrant together, shut off gate valve to isolate Hydrant from

main water source. Loosen (do not remove) one nozzle cap two turns and check for water under pressure inside Hydrant

– bleed off any pressure, then remove nozzle cap completely. Open Hydrant main valve completely. A continuous ow

of water, no matter how slight, indicates Hydrant is not properly isolated from the main water supply, and that problem

must be corrected before any Hydrant disassembly can proceed. Disassembly of Hydrant with pressurized water acting

against the main valve could result in unexpected ejection of Hydrant parts, debris or high-pressure water stream,

which could cause serious bodily injury.

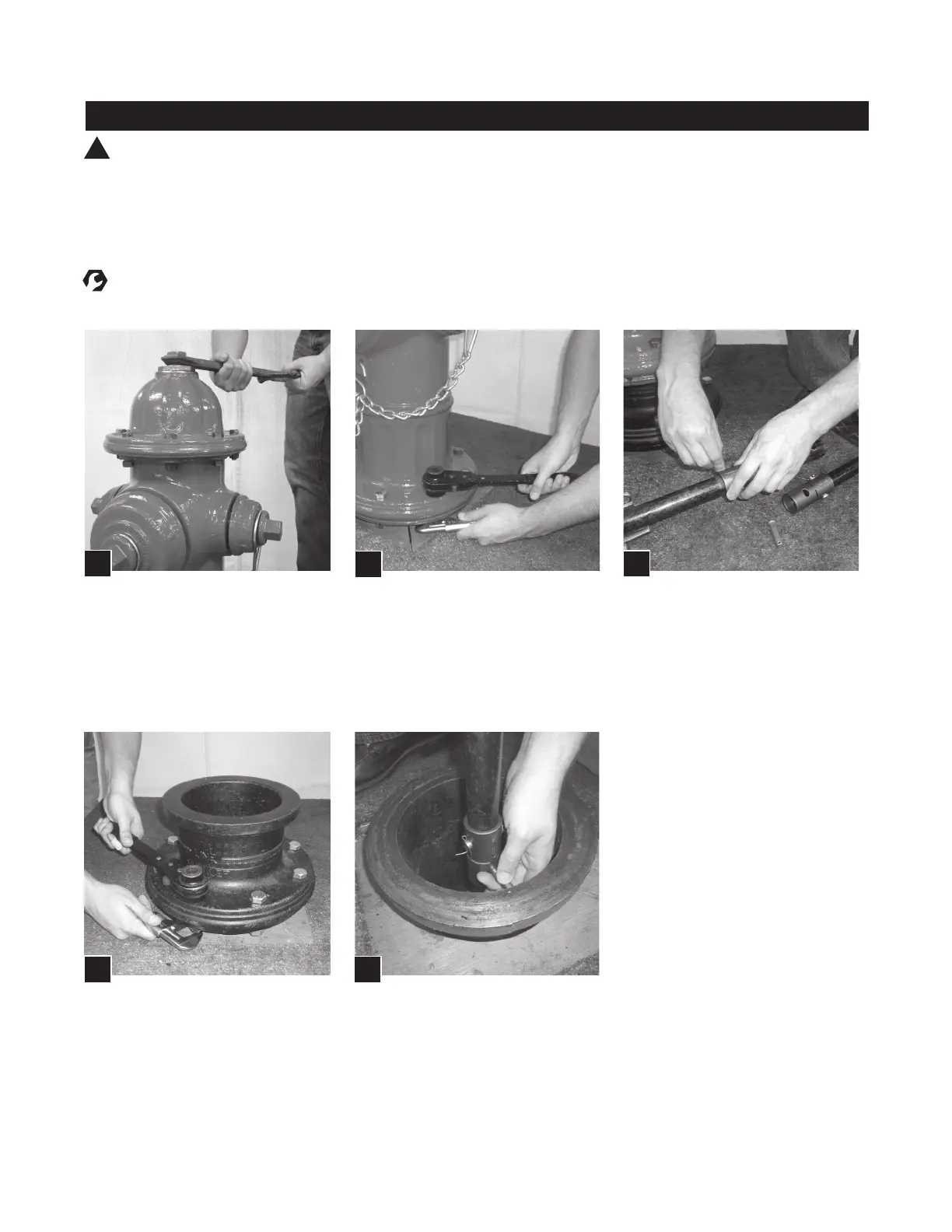

2.

Unbolt Trafc Flange. Remove Upper

Barrel. Remove Upper Stem and

Stem Coupling by removing the lower

stainless steel Cotter Pin and stainless

steel Clevis Pin.

Place Extension Stem and Extension

Coupling on Lower Stem and retain

it with stainless steel Clevis Pin and

stainless steel Cotter Pin.

5.

Assemble Upper Stem and Stem Cou-

pling onto Extension Stem and retain it

with stainless steel Clevis Pin and stain-

less steel Cotter Pin.

NOTE: Make sure Stem Coupling is

installed with “This End Up” towards

the Upper Stem.

1.

Remove Hold-Down Nut, Anti-Friction

Washer and Operating Nut from

Bonnet. Lubricate outside of Brass

Sleeve and slide over threaded stem

end to prevent O-ring damage. Unbolt

Bonnet from Upper Barrel and remove.

Remove Brass Sleeve.

3.

!

2

EQUIPMENT & TOOLS NEEDED – PPE: Hard hat, safety shoes, safety vest, safety glasses, work gloves.

Tools: Wrench, A-311 operating wrench, pliers.

Loading...

Loading...