The ASM150 is a pilot duty device. The outputs are designed for control only.

1.

Wire the ASM150, using 14 AWG (2.5 mm

2

) stranded wire. When wiring to

terminals 2, 13, and 14 (terminals for the power connections), we suggest

using larger wire size (10 AWG [6.0 mm

2

] recommended), this will help to

carry necessary power to the unit during an engine start.

2.

When hooking the battery positive (+) and ground wires to the ASM150, route

them directly from the battery to the unit. This will help reduce electrical noise

coupling and avoid voltage losses from other devices.

3.

If a standby battery charger is installed, it must be wired directly to the battery,

NOT to the ASM150. This could cause electronic "noise" produced by the

charger to be coupled into the microprocessor. If the "noise" is severe, erratic

operation could occur.

4.

Do not route low voltage DC (battery) control wires in the same conduit as

high voltage AC wires.

5.

Use shielded cable for connecting the magnetic pick up to the ASM150.

Ground only one end of the shield (suggest to ground it at the engine).

6.

Always place reverse bias diodes across inductive loads (see “Typical Wiring

Diagram”, Note: 2, below). This increases the contact life and helps eliminate a

source of electro magnetic noise.

7.

Outputs 6 and 15 are rated for 5 A. Outputs 7, 8, 9, 10, 11, and 12 are rated for

300 mA.

8.

Output 7 “Engine Fail IN/OUT” can be used as remote failure output. An exter-

nal device supplying battery positive (+) to the terminal will cause a shutdown.

WARNING:

Disconnect ALL electrical power before beginning the wiring. STOP ALL machinery before performing the hook up.

Any load connected to the panel which draws current in excess of 5

Amps MUST

be piloted at the load. Do NOT short output to ground.

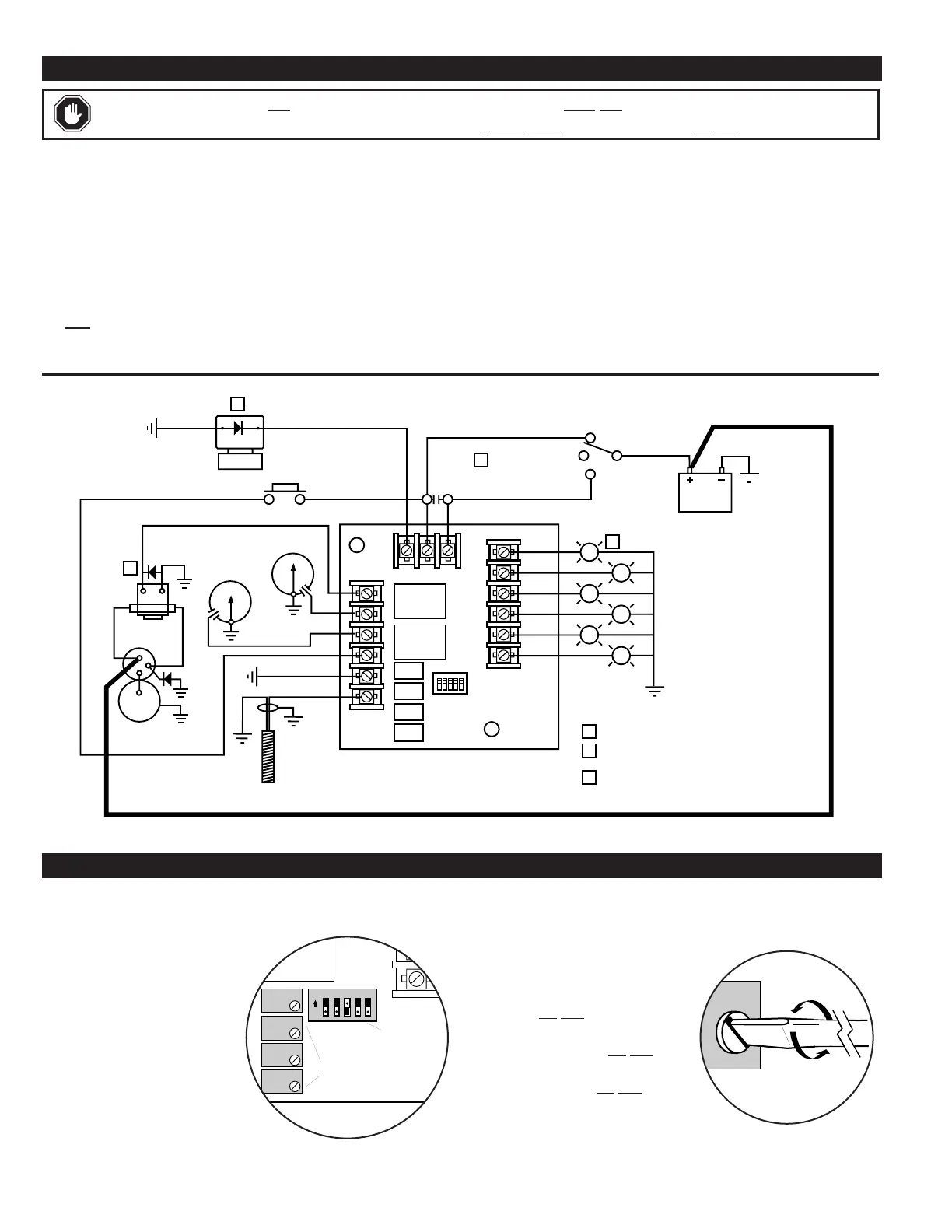

12345

Relay

1

Relay

2

1

2

3

4

5

6

7

8

9

10

11

12

Solenoid

Fuel Valve

131415

Auto

Off

Test

Selector

Switch

Magnetic

Pickup

12/24VDC

Battery

Low Oil Pressure

1

1

3

High Temperature

Overcrank

Overspeed

NOTES

Engine Running

Engine Failure

Normally Open

Push Button

For Lamp Test

Remote

Start/Stop

Switch

Shielded

Cable

Close to start and run, open to stop.

2

Load not to exceed 5 A. Place reverse

bias diodes across induction loads.

3

Remote lights (if used) not to exceed 300 mA.

Starter

Assembly

Pilot

Relay

2

2

High

Temperature

Low Oil

Pressure

WIRING THE ASM150

MAKING ADJUSTMENTS TO THE ASM150

Typical Wiring Diagram

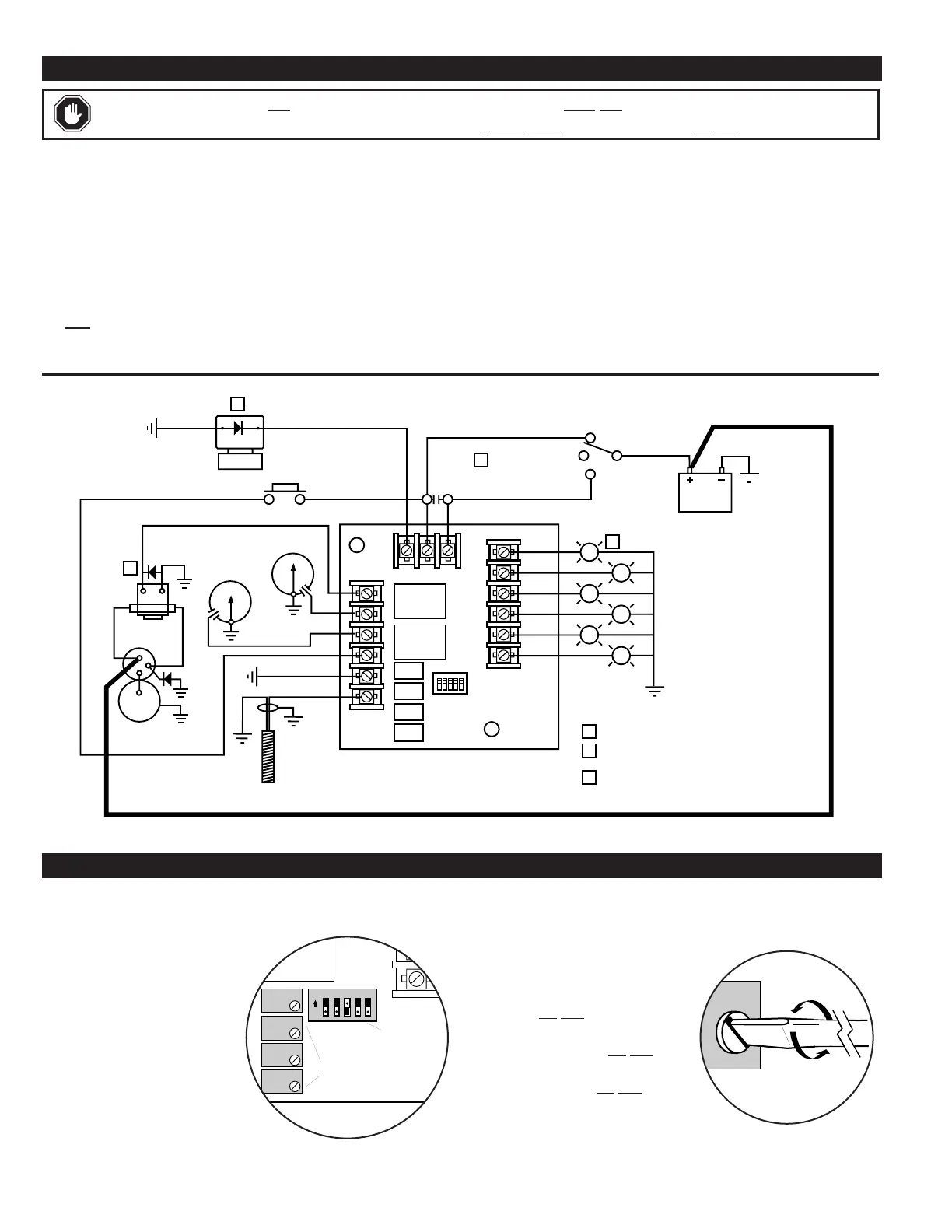

On the back of the ASM150, you will find four

(4) potentiometers and five (5) DIP switches

for customizing your controller. The four

potentiometers are designated as follows:

R1 = Overspeed Adjustment

R2 = Crank Disconnect Adj.

R3 = Crank / Rest Time Adj.

R4 = Shutdown Lockout Delay Adj.

Please note, the factory default set-

tings are approximately 3750 Hz

OVERSPEED, 600 Hz CRANK DIS-

CONNECT, 10 Seconds CRANK/REST,

5 CRANKING ATTEMPTS and 25 Seconds

for SHUTDOWN LOCKOUT DELAY.

Overspeed (R1 Pot)

The OVERSPEED adjustment prevents the

engine from being damaged if there is a malfunc-

tion which causes the engine speed to exceed the

recommended speed.

To set the OVERSPEED value, turn the

OVERSPEED Pot

(R1) fully clockwise and

run the engine up to the maximum operating

speed. Next, slowly turn the Pot (R1) coun-

terclockwise until the engine shuts down on

OVERSPEED. Now, turn Pot

(R1) clockwise

two turns. This will adjust the OVERSPEED set-

point slightly higher than the maximum engine

operating speed.

Relay

2

Potentiometers

DIP

Switches

1

2

3

4

7

8

123 4 5

ON

R1

R2

R3

R4

ASM150 Module

Back View Detail

Potentiometer

Detail

ASM-92152N page 2 of 4

Loading...

Loading...