2203M4JE-MY-iS2-N_2017.04.

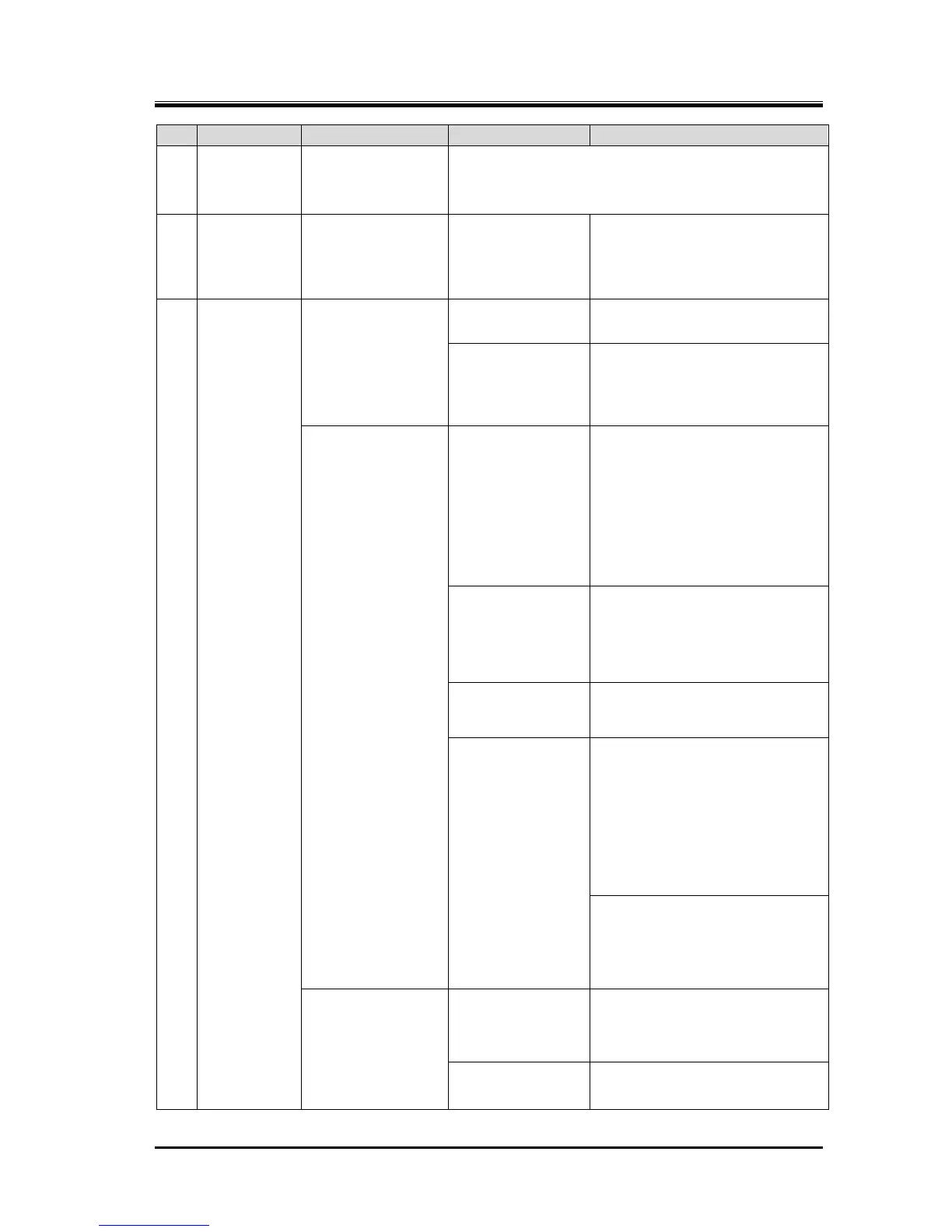

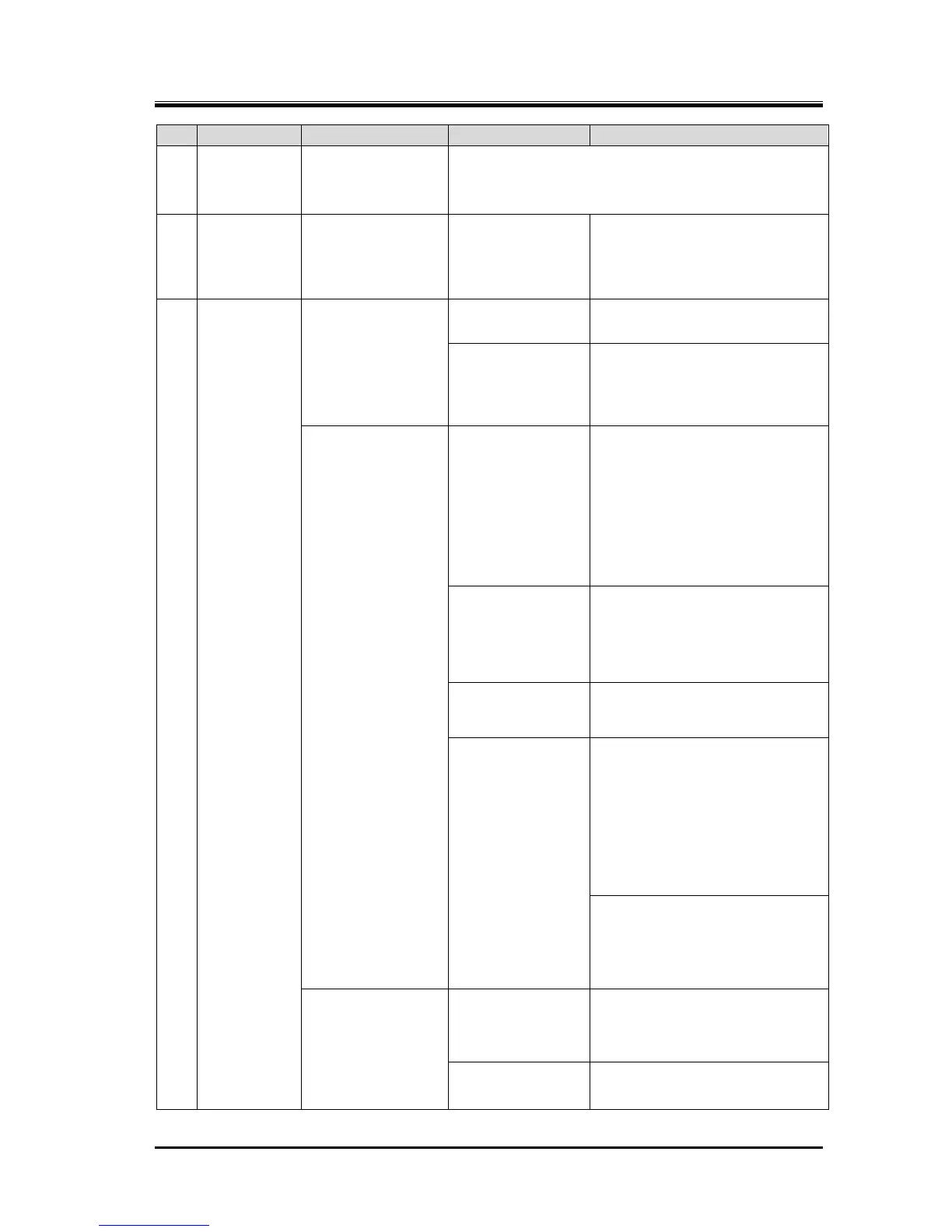

Chapter 6 Troubleshooting

Screw Compressor i-series

6-2

Motor overload that occurs just after startup is mostly

caused not by the refrigeration cycle but by the motor.

Refer to the instruction manual of the motor.

low pressure

(Low suction

pressure)

cause, "Low

pressure protection

circuit activates", in

pressure

(Low oil

supply

pressure)

clogged.

* Pressure

difference

between outlet

and inlet ports is

large.

Remove clogging, and check oil

for contamination/replace oil.

Check for oil contamination and

conduct vibration/noise diagnosis.

Overhaul compressor if

necessary.

functioning,

refrigerant

dissolves

excessively when

the machine is

stopped, and oil

loss occurs at

startup.

Inspect oil heater alone, inspect

relays, etc. on related circuits, and

replace parts as necessary.

return due to

insufficient

refrigerant

circulation

Correct insufficient refrigerant

circulation, and return oil from

load-side heat exchanger.

* Supply lubricating oil temporarily.

clogging in oil

return passage

Remove causes of the trouble,

Inspect machine room and around

the compressor, and take

necessary actions.

Check if there is oil floating in

cooling water system.

→If there is, check for oil leak

from heat transmission tube of

oil cooler and take necessary

actions.

If oil line piping is damaged due to

excessive vibration, take

measures to reduce vibration

(including measures for

resonance vibration).

detection function is

defective.

pressure protection

switch, pressure

sensor, relay, etc.

Identify defective device(s),

investigate causes of failure and

take necessary actions.

Then, replace failed device(s).

Remove clogging, and check oil

for contamination/replace oil.

Loading...

Loading...