2203M4JE-MY-iS2-N_2017.04.

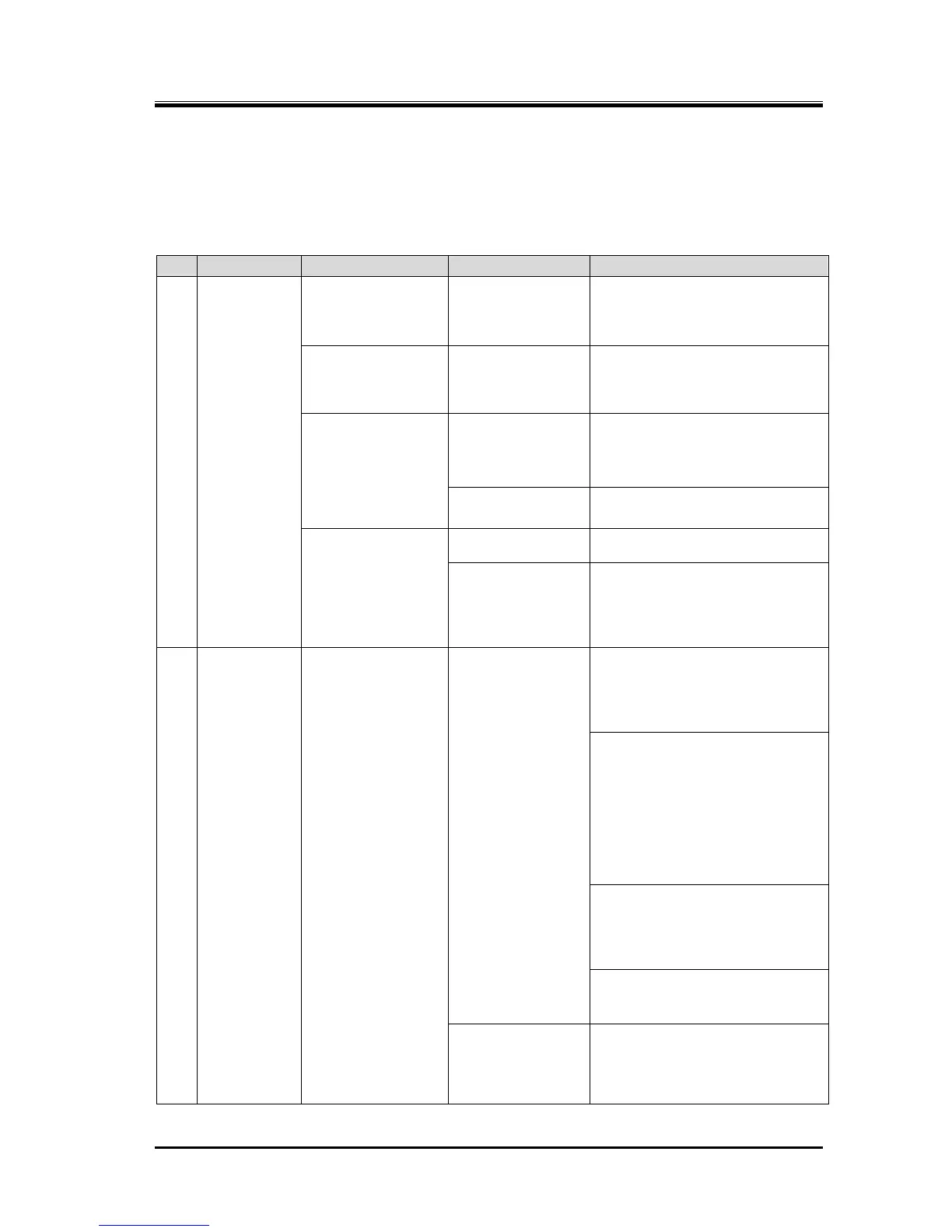

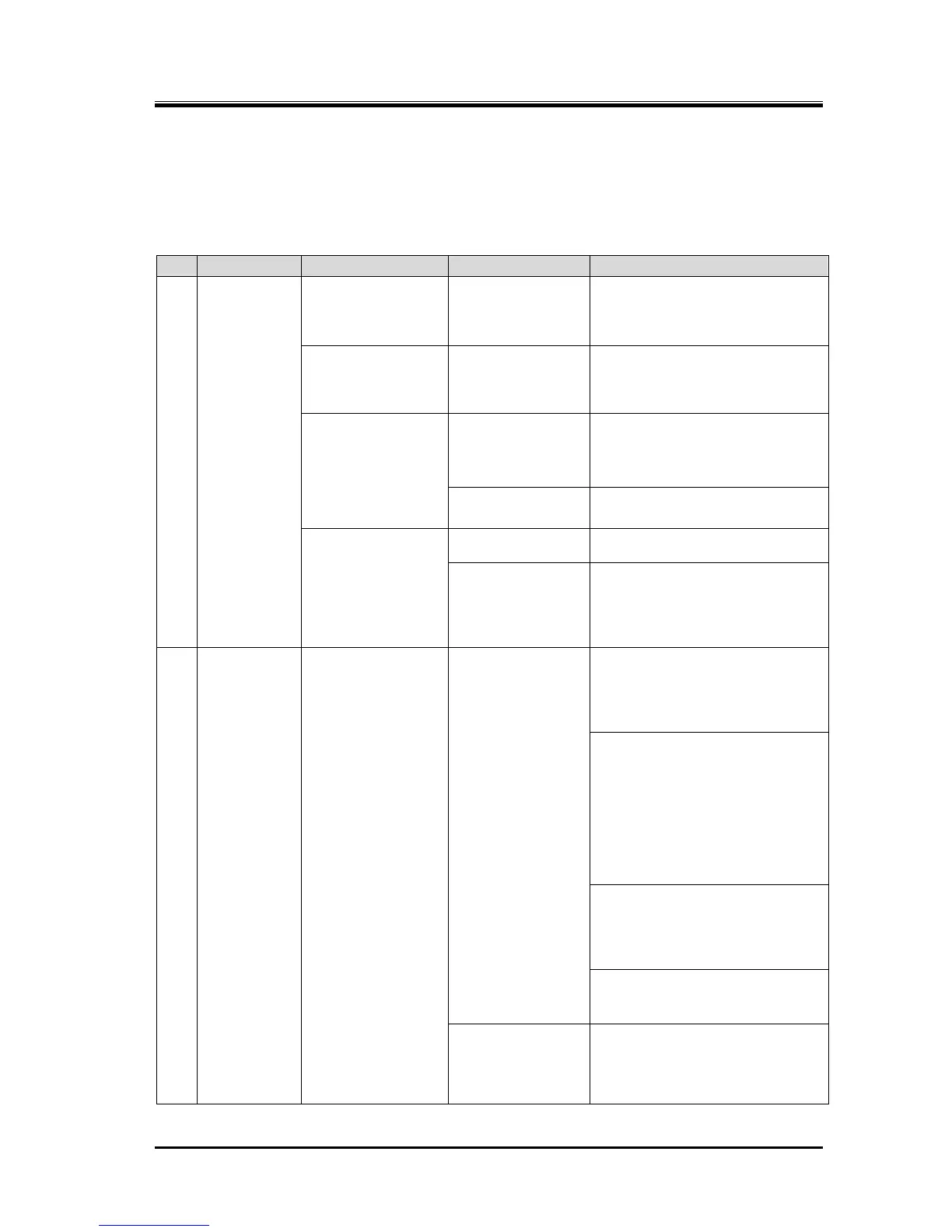

Chapter 6 Troubleshooting

Screw Compressor i-series

6-1

Chapter 6 Troubleshooting

Table 6-1 describes typical trouble symptoms of compressors, their causes and actions to be taken.

The explanations of this Chapter are assumed that the compressor is used in the general refrigeration

cycle.

Table 6-1

Troubleshooting

forgetting to turn on

after inspection.

post-inspection actions and

implement finger pointing and call

check to prevent forgetting.

activation of

overload protection

Refer to the instruction manual of

the motor for details including

other causes and actions.

circulation is not

confirmed.

such as cooling

water pump and

related circuits

Identify defective devices,

investigate causes of failure and

take necessary actions.

Then, replace failed device(s).

relay, etc. in

compressor startup

circuit

Identify defective devices, and

replace with a new one.

Replace ventilation fans, etc. if

defective.

Improve temperature, humidity

and ventilation at the installation

stops

immediately

after startup.

protection circuit

activates.

refrigerant flow

・ Insufficient

refrigerant

・ Insufficient

liquid supply

・ Heat exchange

failure in heat

exchanger

To correct insufficient refrigerant,

check leak, stop leak and then

add refrigerant.

* Also pay attention to moisture

entering into the system.

To correct insufficient liquid

supply, inspect expansion valve

and liquid supply strainer. Take

necessary actions.

In addition, inspect devices and

parameters (set values) of the

expansion valve aperture

adjusting mechanism, and take

(insufficiency) in heat exchange,

such as malfunction of defrosting,

investigate the cause and take

In case of malfunction of pressure

adjustment valve, replace the

valve or remove the cause.

pressure protection

switch, pressure

sensor, relay, etc.

Identify defective devices,

investigate causes of failure and

take necessary actions.

Then, replace failed device(s).

Loading...

Loading...