FIELD CALIBRATION/MAINTENANCE

1. Remove the bottom cover using fingernails or a small

screwdriver to loosen the front or rear edge.

2. Press the button and adjust the Master Calibration Control until

the meter reading is the same as the INTERNAL STANDARD

value.

3. Replace the bottom cover.

RANGE DOUBLING

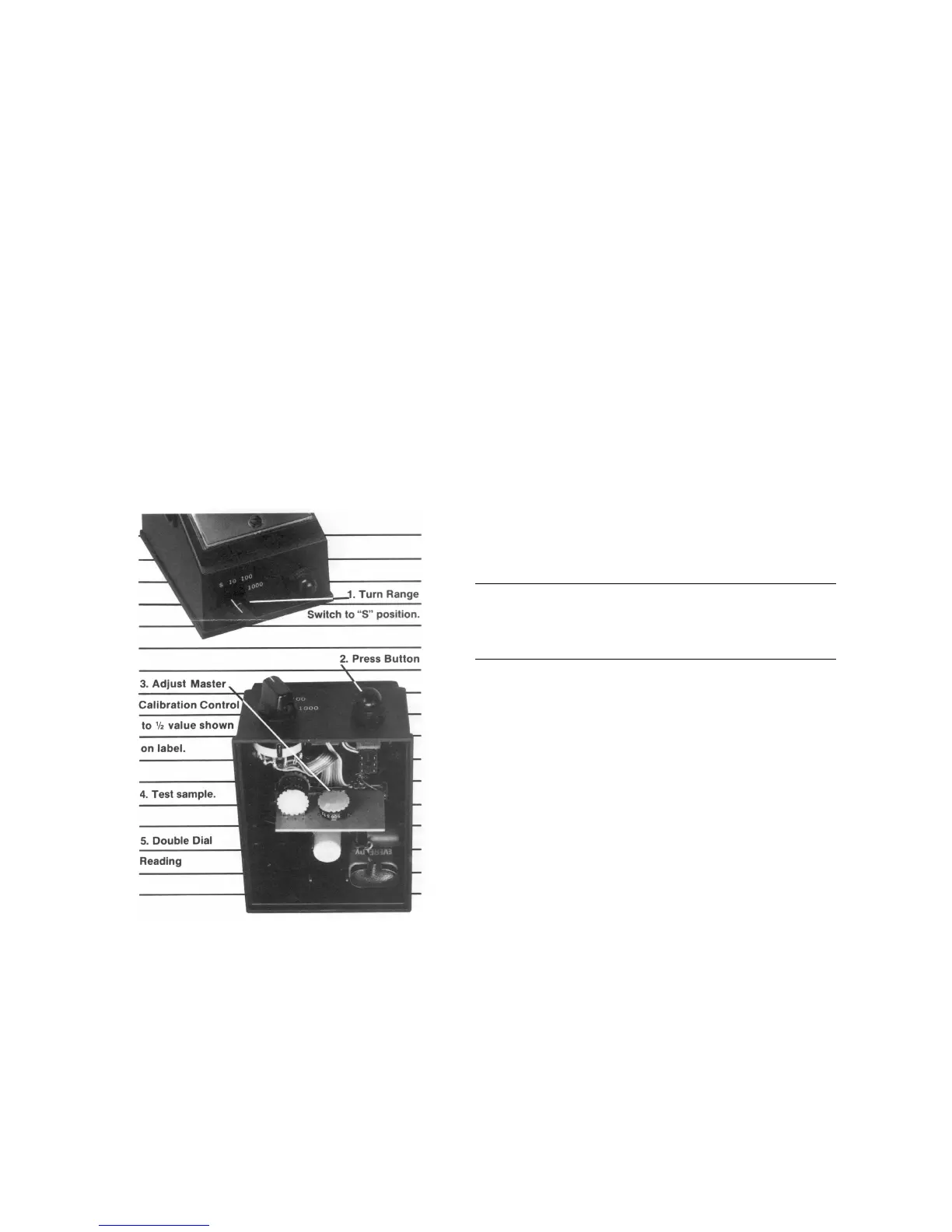

1. Turn the Range Switch to "S". Remove the bottom cover.

2. While pressing the button, adjust the Master Calibration Control

until the meter reads one-half the INTERNAL STANDARD value

shown on the bottom label. For example: If the INTERNAL

STANDARD value is 4.2, adjust the Master Calibration Control

until the reading is 2.1.

3. Test your sample (take care to keep the inside of the meter

dry). Multiply by two the reading of the sample tested. For

example: If the meter reading is 3.2 on the x1000 range (3200),

the actual value of the sample tested is 6400 (3200 x 2).

NOTE:

After completing tests requiring range doubling, reset "S" to its

proper value and replace bottom cover.

EASY STEPS TO DOUBLE RANGE

ACCESSORIES

STANDARD SOLUTIONS

Your DS Meter has been factory calibrated with the appropriate

NIST traceable Standard Solution. All Myron L conductivity

Standard Solution bottle labels show three values: ppm 442, ppm

sodium chloride, and conductivity in micromhos.

442: Unless otherwise specified, the calibration used for all DS

Meters is the "442" standard. The 442 Standard Solutions™ consist

of the following salt ratios: 40% sodium sulfate, 40% sodium

bicarbonate, and 20% sodium chloride. This salt ratio has

conductivity characteristics closely matching natural waters and

was developed by the Myron L Company over three decades ago.

Sodium Chloride: For every ppm 442 Standard Solution, there

is a ppm sodium chloride (NaCI) solution which will have the same

conductivity. The parts per million of the equivalent NaCI solution

is on each Standard Solution label. Instruments calibrated to NaCI

standards are set using equivalent NaCI values.

Conductivity: All Myron L Company Standard Solutions are

traceable to the National Institute of Standards and Technology

and are within 1.0% of Potassium Chloride reference solutions.

The concentrations of the reference solutions are calculated from

data in the International Critical Tables, Vol. 6.

RECOMMENDED STANDARD SOLUTIONS

MODEL/RANGE SOLUTION NUMBER

532T1

x 10 442-30

x 100 442-300

x 1000 442-3000

with RE-10 442-30,000

532T2

x 10 442-15

x 100 442- 150

x 1000 442-1500

with RE-10 442-15,000

532M1

x 10 442-30

x 100 442-300

x 1000 442-3000

with RE-10 442-30,000

RANGE EXTENDER

The RE-10 Range Extender is a useful accessory for testing

high conductivity/ppm solutions beyond the normal range of your

DS meter. Inserting the RE-10 into a sample-filled cell cup increases

the maximum range ten times. Use the Range Extender whenever

the reading is off the scale.

USING THE RE-10

1. Fill the cell cup three times to rinse it, but each time insert the

Range Extender to rinse it also.

2. Fill the cell cup with your sample. Push the Range Extender

into the cell cup, seating the O-ring seal.

3. Use and read the DS Meter in the normal manner. Multiply the

reading by 10.

4. For best accuracy, repeat the complete test with a fresh sample.

5. When you're done testing, remove the Range Extender.

Thoroughly rinse the cell cup and Extender with clean water

(preferably distilled or deionized) to eliminate dried salts build-

up. This is extremely important when the instrument will be

used to test high purity water.

MAINTENANCE

BATTERY CHECK

1. Turn the Range Switch to "S" and press the button. Adjust the

Master Calibration Control to maximum.

2. If the meter reads less than full scale the battery should be

replaced. Remove the bottom cover. Detach the battery

connector. Pull on the vinyl strap to remove the battery. Replace

with a fresh zinc carbon or alkaline 9 volt battery. Reinsert the

vinyl strap to secure battery.

Loading...

Loading...