USING YOUR METER

1. Turn the Range Switch to the desired range. If you don't know

which range to use, set it to 1000.

2. Rinse the cell cup three times with the sample you want to test.

(For very hot or very cold samples see TEMPERATURE

COMPENSATION below.)

NEVER FILL THE CELL BY DIPPING THE METER INTO WATER!

3. Fill the cell with another sample to at least 1/4" (6 mm) above

the upper electrode.

4. Press the black button.

5. Read the dial value indicated by the pointer. If the pointer is

very low on the left or goes off the scale to the right, try the next

lower or higher range.

6. Multiply the dial value by the range setting to determine parts

per million (ppm) Total Dissolved Solids on the 532T models or

the conductivity in micromhos (µmhos) on the 532M1.

7. If the pointer goes off the scale to the right on the x1000 range,

try RANGE DOUBLING (see inside) or an RE-10 Range

Extender (see ACCESSORIES).

NOTE:

When you are finished with the meter, RINSE THE CELL CUP

with clean water, preferably distilled or deionized.

TEMPERATURE COMPENSATION: For very hot or very cold

solutions let the three rinse samples each remain in the cell for

several seconds. Then immediately fill the cell with the sample

you want to test (step 3 above). This allows the automatic

temperature compensation feature time to work properly.

CAUTION

DO NOT use with samples hotter than 160°F (71°C).

The readings WILL NOT be accurate.

DO NOT splash solvents such as lacquer thinner, acetone,

benzene or chlorinated solvents on the plastic case.

DO NOT fix or modify the meter. That will void your warranty.

See SERVICE for details or consult Myron L Company.

DO NOT DIP THE INSTRUMENT INTO WATER. If water does

get inside the instrument, see MAINTENANCE for instructions on

drying it.

CALIBRATION

STANDARD SOLUTIONS: A Standard Solution has a known

conductivity and ppm. Your meter was calibrated at the factory

using NIST traceable Standard Solutions. You can keep your meter

accurate by using these same Standard Solutions. To pick the right

Standard Solution for your meter see ACCESSORIES.

CHECKING CALIBRATION

1. Turn the Range Switch to the x1000 range.

2. Test a sample of appropriate Standard Solution.

CAUTION: Throw the Standard Solution away as you use it. Don't

put the used samples back in the bottle.

3. If the DS Meter does not indicate the same value as is on the

Standard Solution bottle's label, first clean the cell. For directions

on how to do this see CELL inside. Rinse the cell thoroughly

and test the Standard Solution again. If the DS Meter still does

not indicate the correct value, recalibrate it as described below.

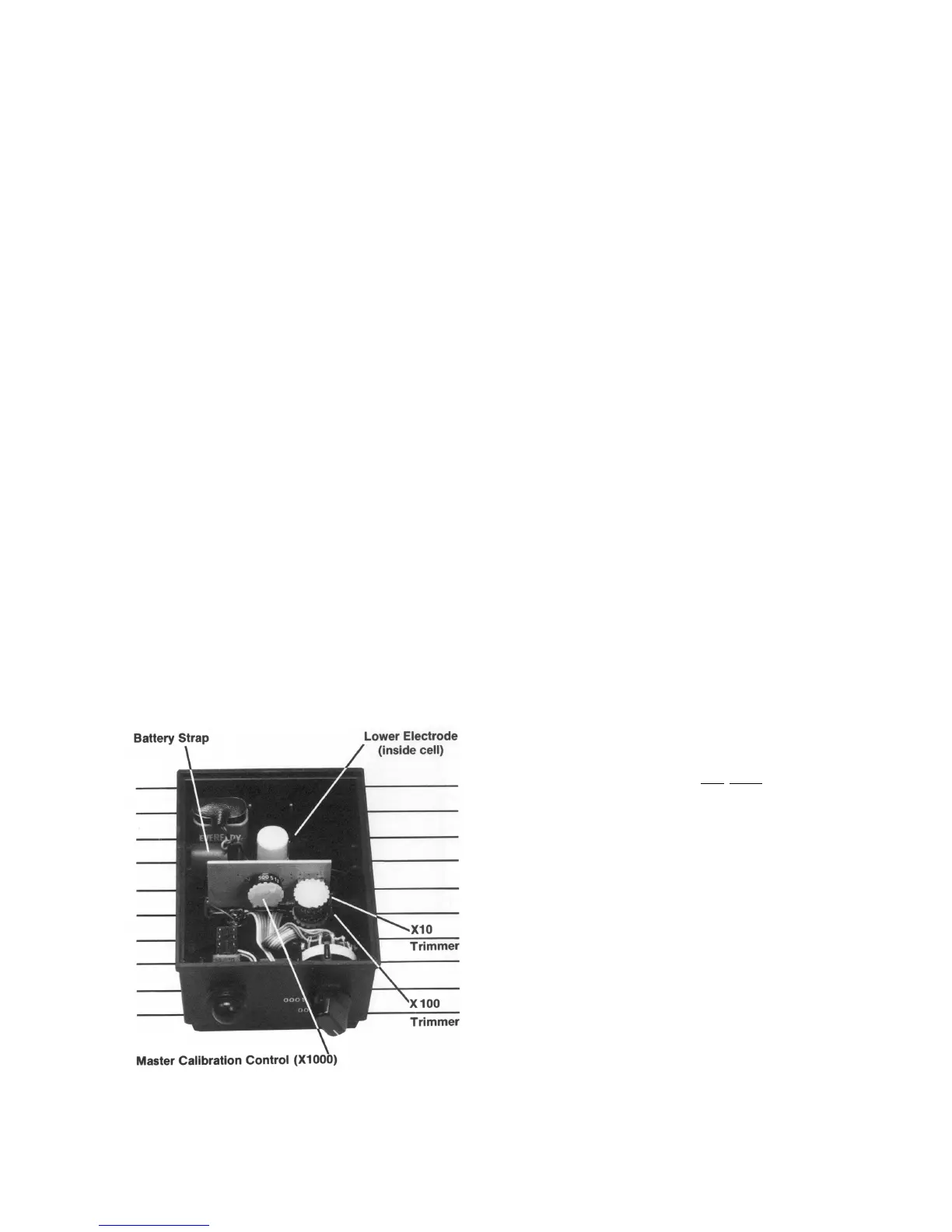

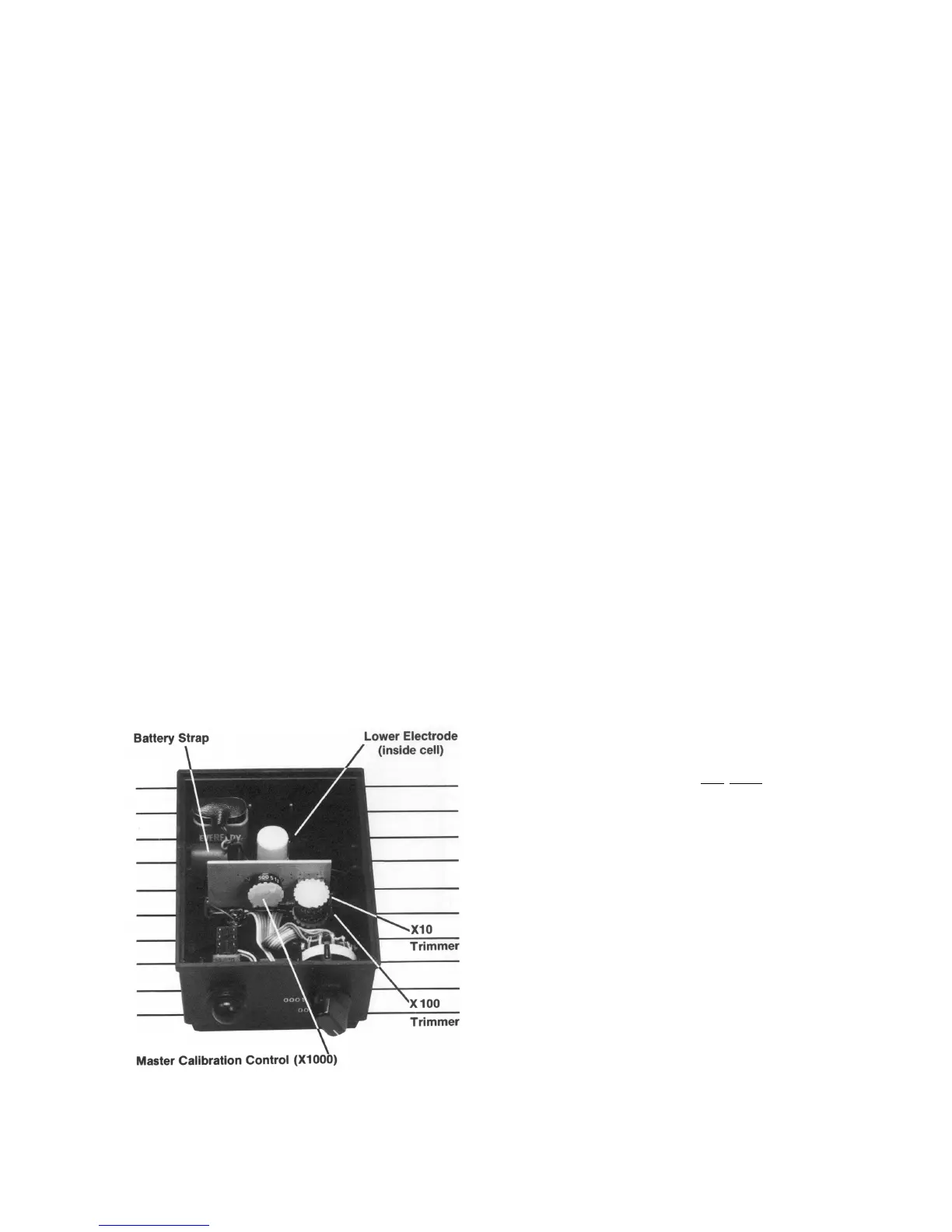

TO RECALIBRATE THE METER

1. Remove the bottom cover using fingernails or a small

screwdriver to loosen the front or rear edge. Identify the three

Calibration Controls (see photo below left) so you can find them

by touch while calibrating.

2. Test another sample of the Standard Solution (be careful to not

to splash solution inside the meter).

3. Adjust the Master Calibration Control until the meter indicates

the value that is on the Standard Solution label.

4. The Master Calibration Control adjusts all ranges. For best

accuracy in the lower ranges, get the recommended Standard

Solutions for the x100 and x10 ranges. Use the x100 and x10

trimmers to recalibrate those ranges as in steps 2 and 3 above.

5. Turn the Range Switch to "S" and press the button. Compare

the meter reading to the INTERNAL STANDARD value on the

meter's bottom label. If they are noticeably different, mark the

new value in place of the old one.

NOTE:

A 532T (ppm) Meter may be calibrated to read either 442 or

NaCI parts per million, but not micromhos. A 532M1 (conductivity)

Meter may only be set to read micromhos.

INTERNAL STANDARD: An INTERNAL STANDARD value for

each meter is on the label on the bottom cover of each meter. Use

it between normal calibrations as a

field check of your meter's

accuracy.

To verify your meter's calibration:

1. Turn the Range Switch to "S" and press the button.

2. If the reading matches the INTERNAL STANDARD value on

the bottom label, your meter is in calibration. If not, see FIELD

CALIBRATION.

NOTE:

The feature described above is intended as a quick field

calibration check, or for using the range doubling technique. It is

not a replacement for calibration with Standard Solution.

Loading...

Loading...