Chapter 8 Maintenance and inspection

68

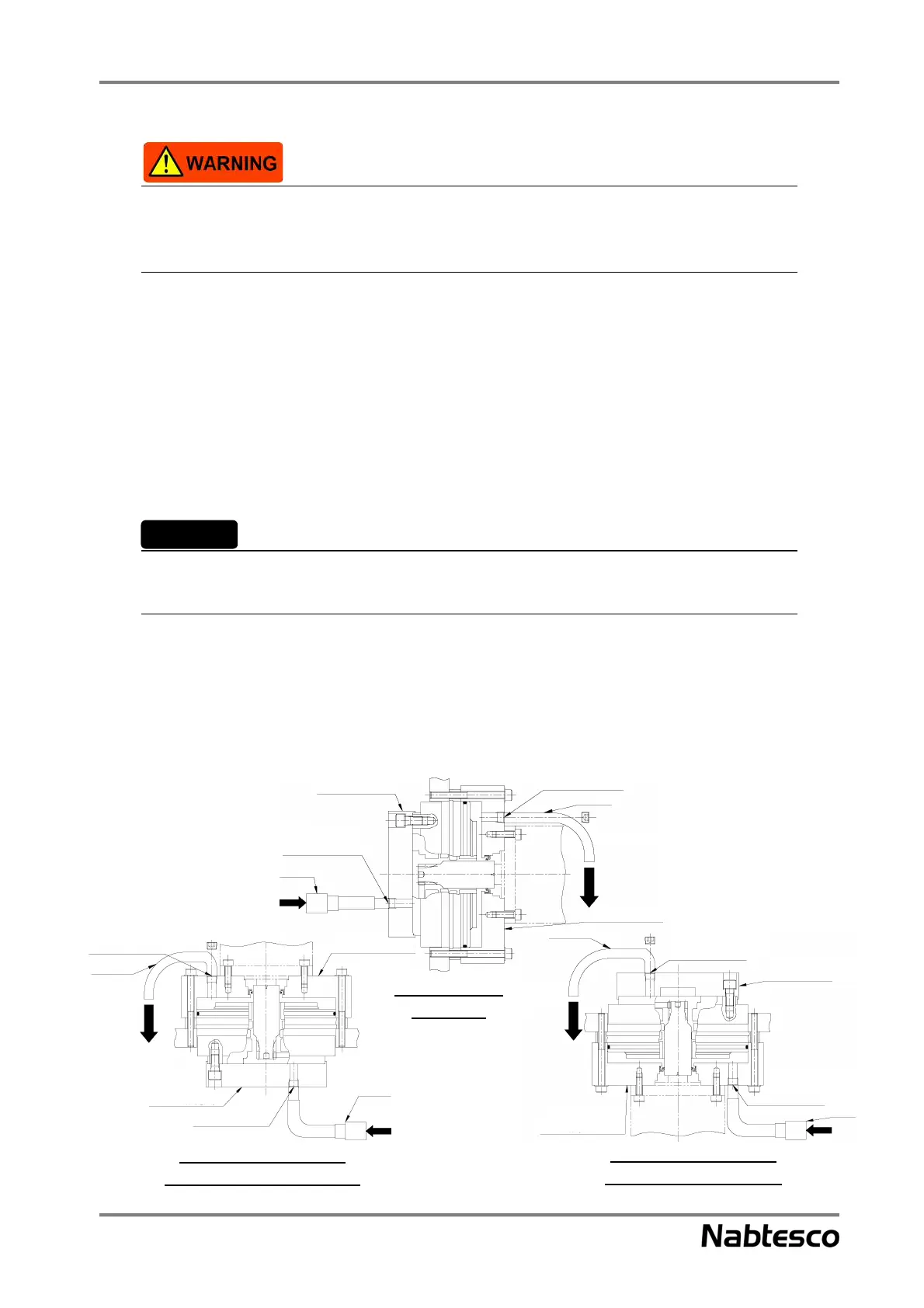

Fig. 8-2

Vertical shaft installation

(with shaft facing downward)

Vertical shaft installation

(with shaft facing upward)

Horizontal shaft

installation

component

injecting/draining

injecting/draining

injecting/draining

grease (drain

lubricant)

injecting/draining

grease (supply side)

Tapped hole for injecting/

injecting/

draining grease

mounting flange

mounting flange

Do not use the motor to rotate the output shaft of the reduction gear for safety, if possible. If the motor

is used by necessity, run the motor at a low speed and never touch the rotation section. Otherwise,

you could be caught by the rotation section, which will result in serious injury.

• Repeat steps 3 to 8 until the reduction gear is filled with the same amount of lubricant as that was

Step 9

drained.

• It is recommended that the inside of the reduction gear is flushed so that the lubricant can be

Step 10

replaced more efficiently.

• Remove the injector from the tapped hole on the supply side, and attach a hexagon socket head cap

plug to the tapped hole on the drain side. Calculate output shaft conversion and set the motor

rotation speed so that the output shaft rotation speed is 5 to 10 rpm. Then, rotate the motor for

about one minute.

Set the rotation speed based on the output shaft conversion by taking the customer’s operation

conditions into account.

• Perform steps 1 and 9 again.

Step 11

• Attach the hexagon socket head cap plugs to the tapped holes for injecting/draining grease.

Step 12

Replace the seal tape with a new one.

• Wipe off the lubricant adhering to the surrounding completely.

Step 13

Important

Loading...

Loading...