3.5 Tool constant settings

The “tool constants” refer to a set of parameters including the length, angle, center of gravity, weight and

moment of inertia of the installed tool. These parameters are extremely important for ensuring precise linear

operations and appropriate acceleration/deceleration control. Before moving the robot, read carefully through

the instructions in this section and take the

steps described without fail. Tool constants for up to 32

stored in this controller’s memory. If an application involves the use of a multiple number of tools, perform the

settings for all the tools

Continued use under the wrong settings for the center of gravity, weight and tool’s

moment of inertia may fatally damage the machine. Perform the settings set forth in this

The settings must be performed even for small and/or lightweight tools. The same

settings used for a large tool cannot be used for a small tool.

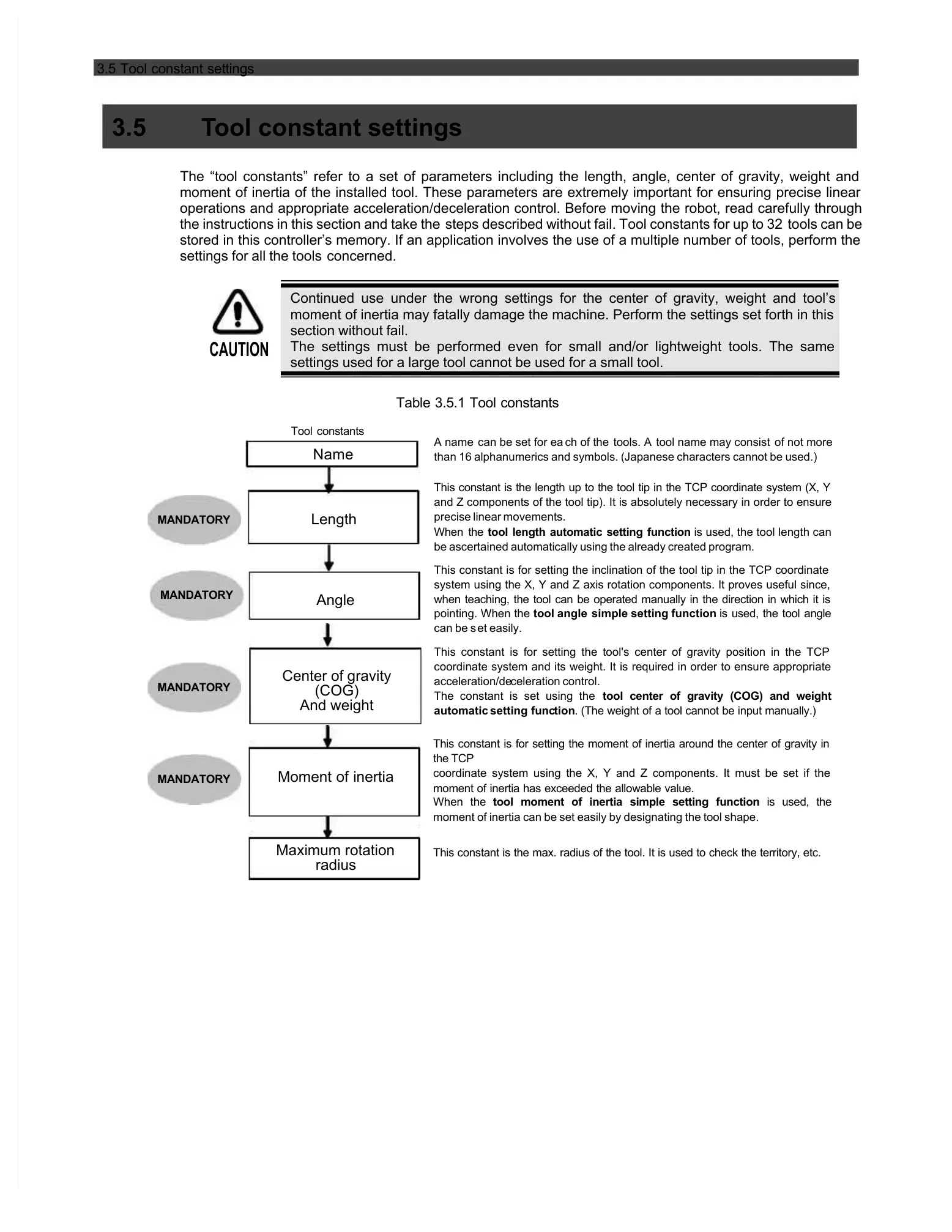

Table 3.5.1 Tool constants

This constant is the length up to the tool tip in the TCP coordinate system (X, Y

and Z components of the tool tip). It is absolutely necessary in order to ensure

precise linear movements.

tool length automatic setting function

is used, the tool length can

be ascertained automatically using the already created program.

This constant is for setting the inclination of the tool tip in the TCP coordinate

system using the X, Y and Z axis rotation components. It proves useful since,

when teaching, the tool can be operated manually in the direction in which it is

This constant is for setting the tool's center of gravity position in the TCP

coordinate system and its weight. It is required in order to ensure appropriate

The constant is set using the

tool center of gravity (COG) and weight

. (The weight of a tool cannot be input manually.)

than 16 alphanumerics and symbols. (Japanese characters cannot be used.)

This constant is for setting the moment of inertia around the center of gravity in

coordinate system using the X, Y and Z components. It must be set if the

moment of inertia has exceeded the allowable value.

tool moment of inertia simple setting function

moment of inertia can be set easily by designating the tool shape.

This constant is the max. radius of the tool. It is used to check the territory, etc.

Loading...

Loading...