48 EN

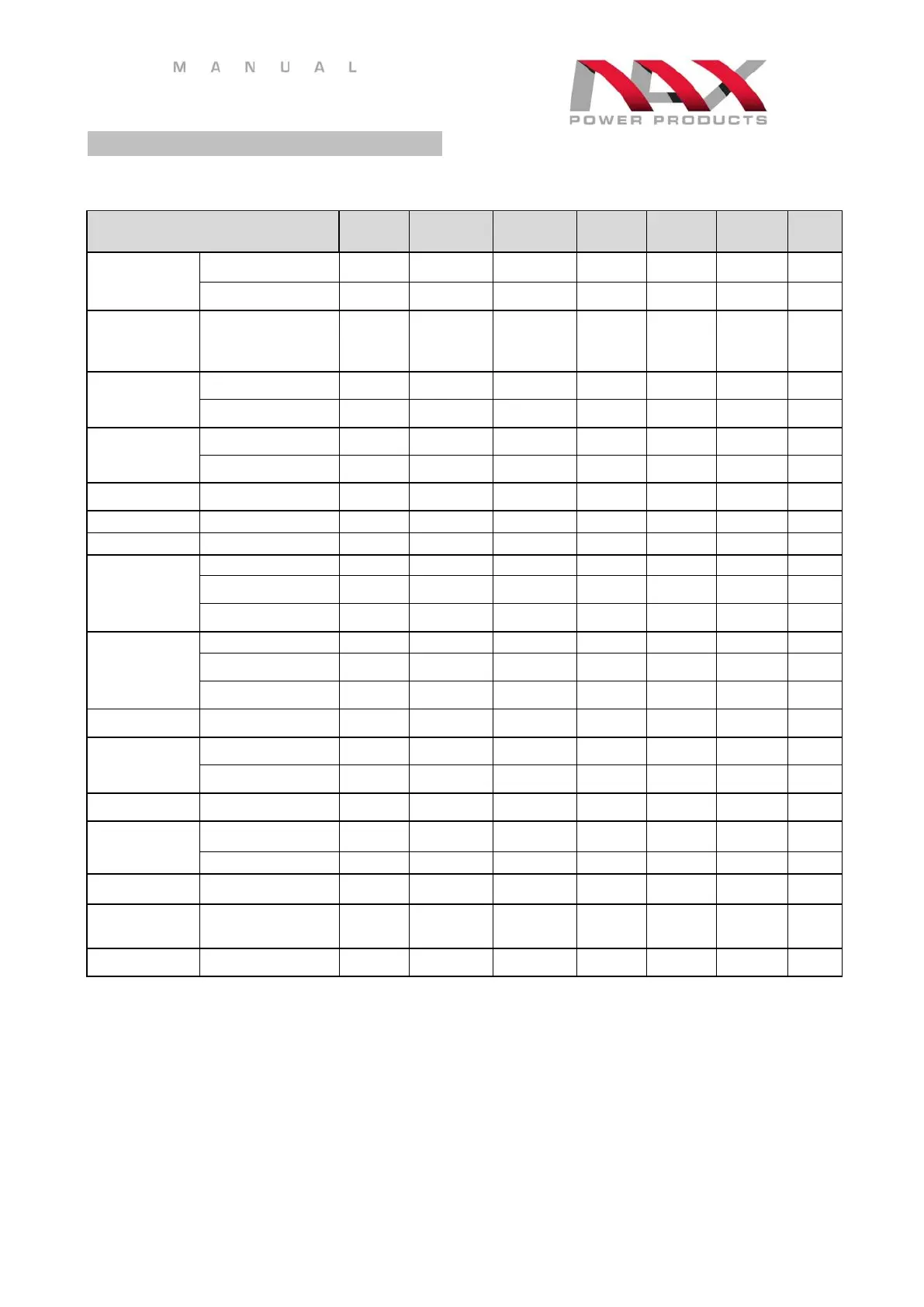

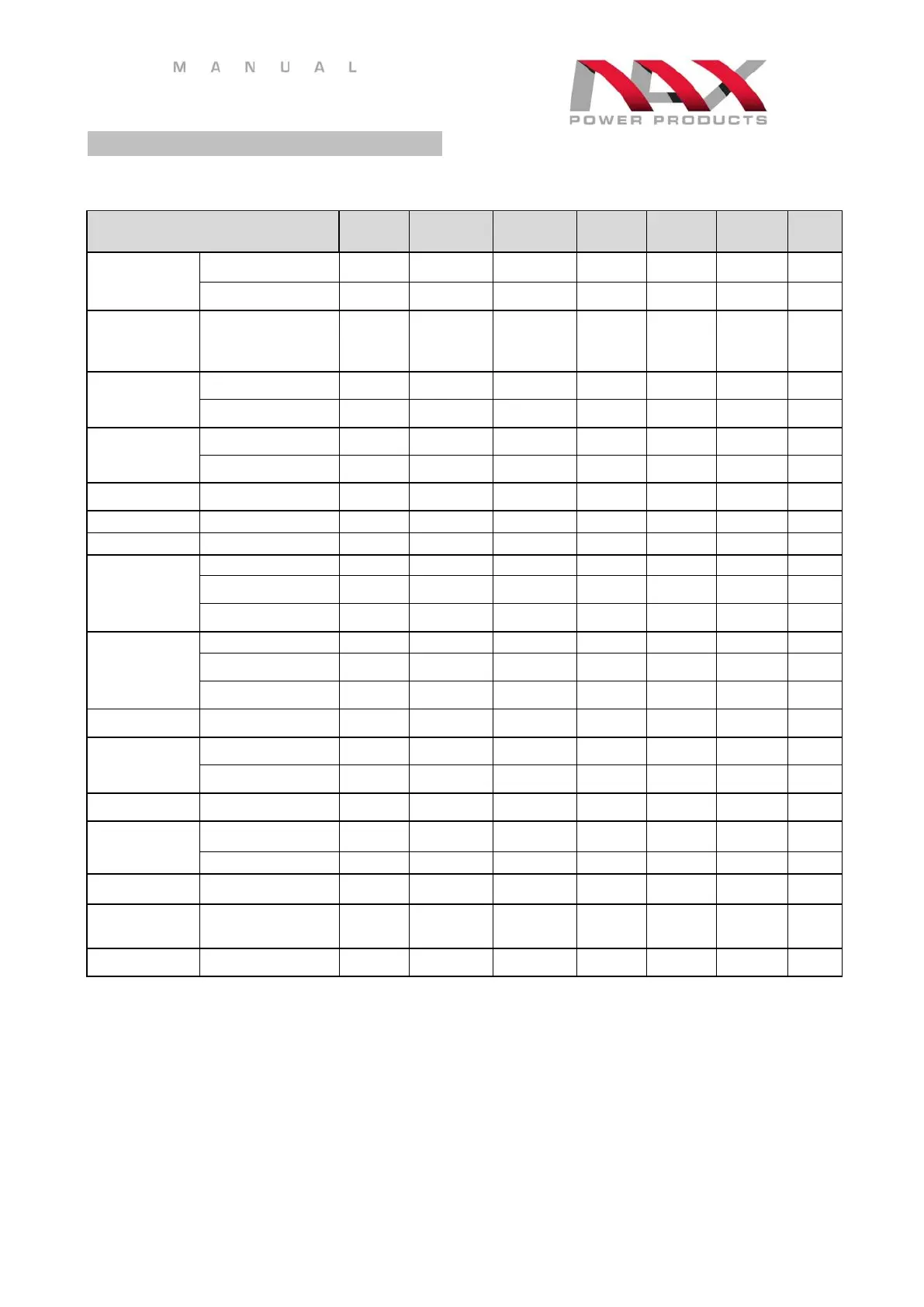

REVIEW AND DIAGNOSIS OF PROBLEMS

INSPECTIONS

visually check (condition,

leaks)

Throttle switch and

lock, combination

switch

Fuel filter in the fuel

tank

check, check of sharpness

check for wear and damage

check the idle adjustment -

the chain cannot rotate

adjust the gap between the

electrodes

All available nuts and

bolts (except for

adjusting bolts)

The above maintenance intervals only apply to normal machine operating conditions. If the daily working time is longer than normal or

the cutting conditions are difficult (very dusty surroundings, resin-rich wood, tropical wood, etc.), then the indicated actions should be

performed much more often.

Loading...

Loading...