GEO M12 HARDWARE SETUP PROCEDURE Page 47/90

IMPORTANT

Maximum GEO M12 quantity for flown vertical cluster with GMT-LBUMPM12 is 12 (and

eventually less).

Please check NS-1 for mechanical Safety Working Load and acoustic computations.

IMPORTANT

Motor hoist must be rated to support entire cluster weight. Please check configuration

in NS-1 for proper motor hoist rating

Procedure

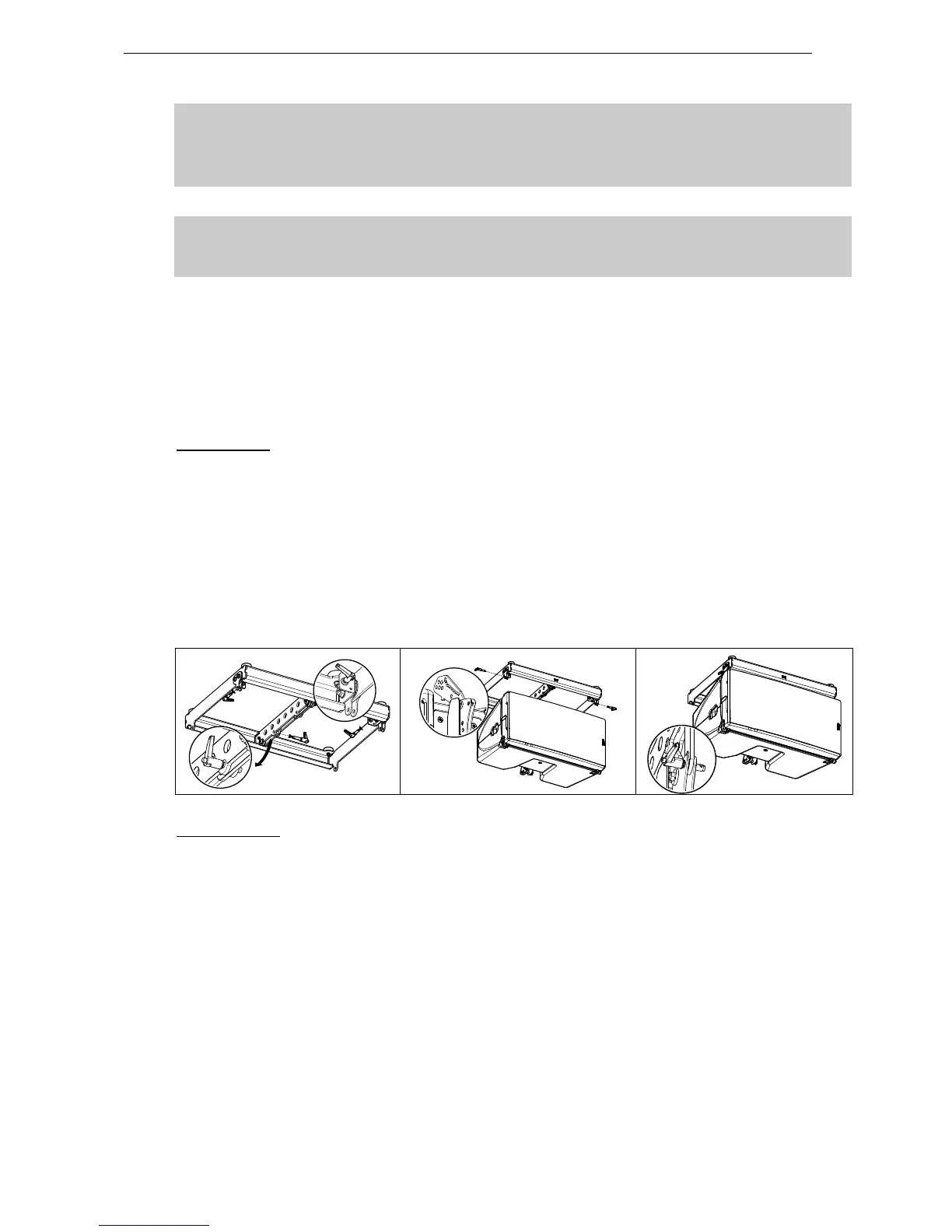

GMT-LBUMPM12 can be flipped front and back depending if its connects to GEO M12 Right or Left.

- When connecting GEO M12 Left, bumper front is on the “A” hole index side

- When connection GEO M12 Right, bumper front is on the “G” hole index side

GEO M12 Left

- Position first GEO M12 so that Autorig

TM

is at the bottom

- Position bumper (“A” hole at front) on top of first GEO M12

- Remove the two BL820 quick release pins from their side storage position, and the BL825 quick

release pin of rear bumper link bar.

- Connect bumper front points to GEO M12 with the BL820 quick release pins

- Connect the bumper link bar (0° position) to GEO M12 rear rigging plate (hole marked “bumper”) Lock

with the quick release pin BL0825.

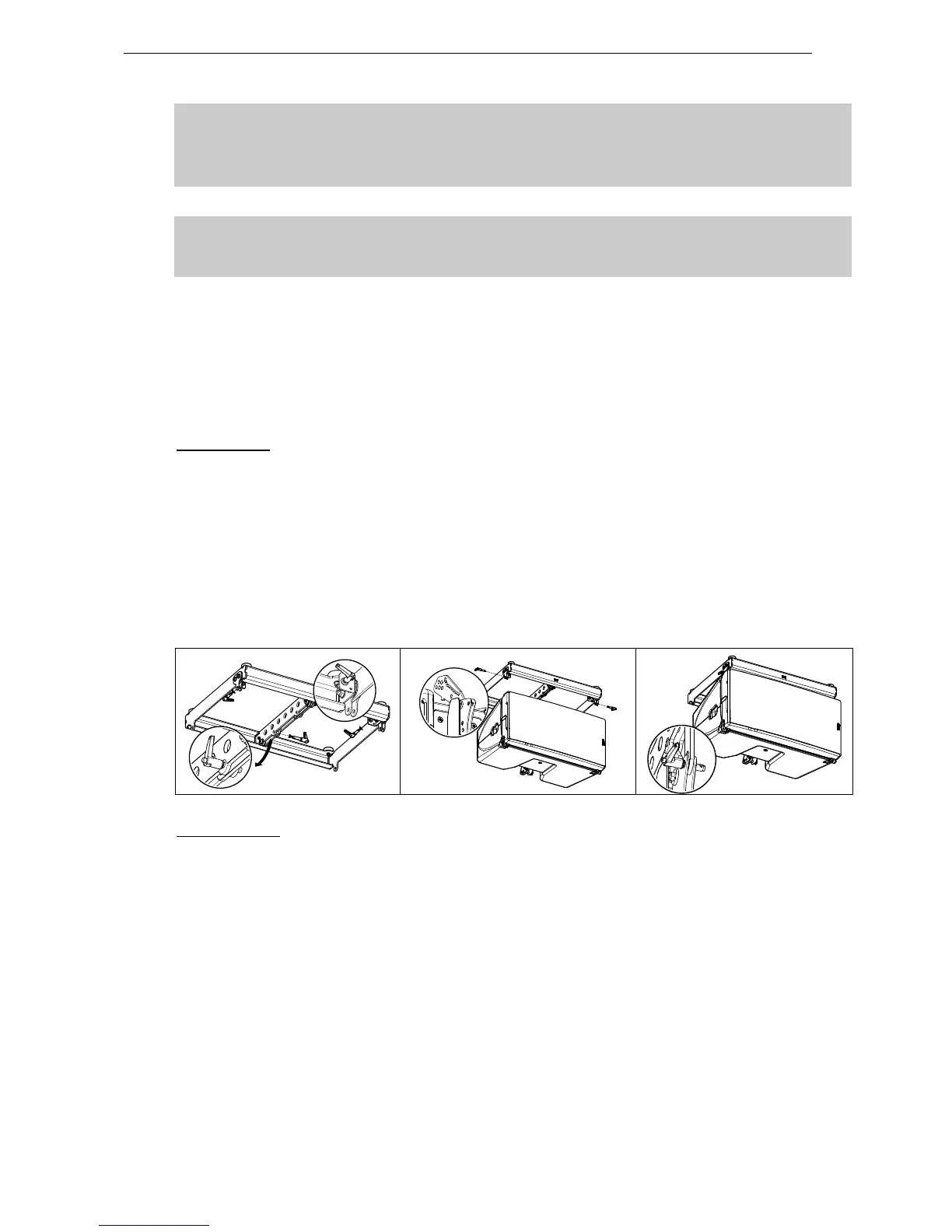

GEO M12 Right

- Position GEO M12 so that Autorig

TM

is at the top and set in automatic lock position

- Position bumper (“G” hole at front) on top of first GEO M12

- Remove the the BL825 quick release pin of rear bumper link bar.

- Connect bumper front points to GEO M12, front points will lock automatically

- Connect the bumper link bar (0° position) to GEO M12 rear rigging plate (hole marked “bumper”) Lock

with the quick release pin BL0825.

Loading...

Loading...