Installation, Operating and Maintenance Instructions Installation, Operating and Maintenance Instructions

®®

2 3

Installation Instructions

1

F721APLL, F721APLG, F721APSL and F721APSG with LD2000 Series Butterfly

Valves.

1. Ensure internal diameter of flanges, fittings, and pipe are compatible with the

butterfly valve for proper seal-face integrity and disc operation. See NIBCO Rubber

Lined Butterfly Valve IOM for additional details as necessary.

2. Ensure the mating pipeline flange faces are clean and undamaged, and the pipe

bores are clean and free from debris.

3. Close the valve completely to avoid possible damage.

Position the kit into the pipeline, taking care not damage the integrally molded seat

4. liner.

5. Insert the strainer flange gasket.

6. NIBCO LD2000 series butterfly valves have integral rubber faces that seal to the

attaching flange; therefore, a separate gasket is not necessary and should not be

used.

7. Carefully open the valve to assure free unobstructed disc movement.

8. After proper operation is verified, tighten all fasteners to the minimum

recommended torques listed below, using a crisscross pattern as shown in below in

Figure 1.

NOTE: Care shall be taken to prevent over tightening to prevent possible product

and property damage.

9. Cycle the valve to confirm unobstructed disc movement.

F721APNL and F721APNG with N200 Series Butterfly Valves.

1. Ensure internal diameter of flanges, fittings, and pipe are compatible with the

butterfly valve for proper seal-face integrity and disc operation. See NIBCO Rubber

Lined Butterfly Valve IOM for additional details as necessary.

2. Ensure the mating pipeline flange faces are clean and undamaged, and the pipe

bores are clean and free from debris.

3. Close the valve completely to avoid possible damage.

4. Position the kit into the pipeline, taking care not damage the cartridge seat liner.

Insert the strainer flange gasket. NIBCO N200 series butterfly valves have rubber

5. faces that seal to the attaching flange; therefore, a separate gasket is not necessary

and should not be used.

6. Carefully open the valve to assure free unobstructed disc movement.

7. The strainer-to-valve bolting will also need to be properly tightened.

8. The F721APNL and F721APNG kits are shipped with strainer-to-valve bolting in the

hand tight condition.

Installation Instructions Continued

F721APNL and F721APNG with N200 Series Butterfly Valves.

9. The cartridge style seat construction of the N200 series butterfly valve prohibits

complete tightening prior to installation in the piping system.

10. After proper operation is verified, tighten all fasteners to the minimum

recommended torques listed below, using a crisscross and cross-over pattern as

shown below.

10.1 It is critical that the cartridge liner be evenly compressed from both sides

ofthe mating flanges. (Refer to NIBCO Technical Bulletin - Installation Precautions

and Instructions for Large-Diameter Cartridge-Liner Butterfly Valves, NTB-1012-03

for additional details).

10.2 NIBCO recommends a multi-stepped process utilizing the crisscross and cross-over

pattern be used to draw the flanges against the liner from both side of the valve

at the same rate, ensuring the liner is compressed evenly. See Figure 2.

NOTE: Care shall be taken to prevent over tightening to prevent possible product

and property damage.

11. Cycle the valve to confirm unobstructed disc movement.

Maintenance

See NIBCO F721AP Strainer IOM for strainer maintenance.

See NIBCO Rubber Seated Butterfly Valve IOM for valve maintenance.

These documents, and more are available at NIBCO.com

Shipment and Storage

Butterfly valve discs are shipped in the nearly closed position to protect the sealing edge

and prevents the liner from taking a temporary set. The stem bushings and disc edge have

been coated with a factory-applied lubricant to prolong storage and service life.

The kits may be shipped or stored in any position, but care shall be taken to protect the

valve actuation hardware. Valves shall be stored indoors, and for a maximum of 10

years between a temperature range of 40˚ F to 90˚ F (4˚C to 32˚C).

2

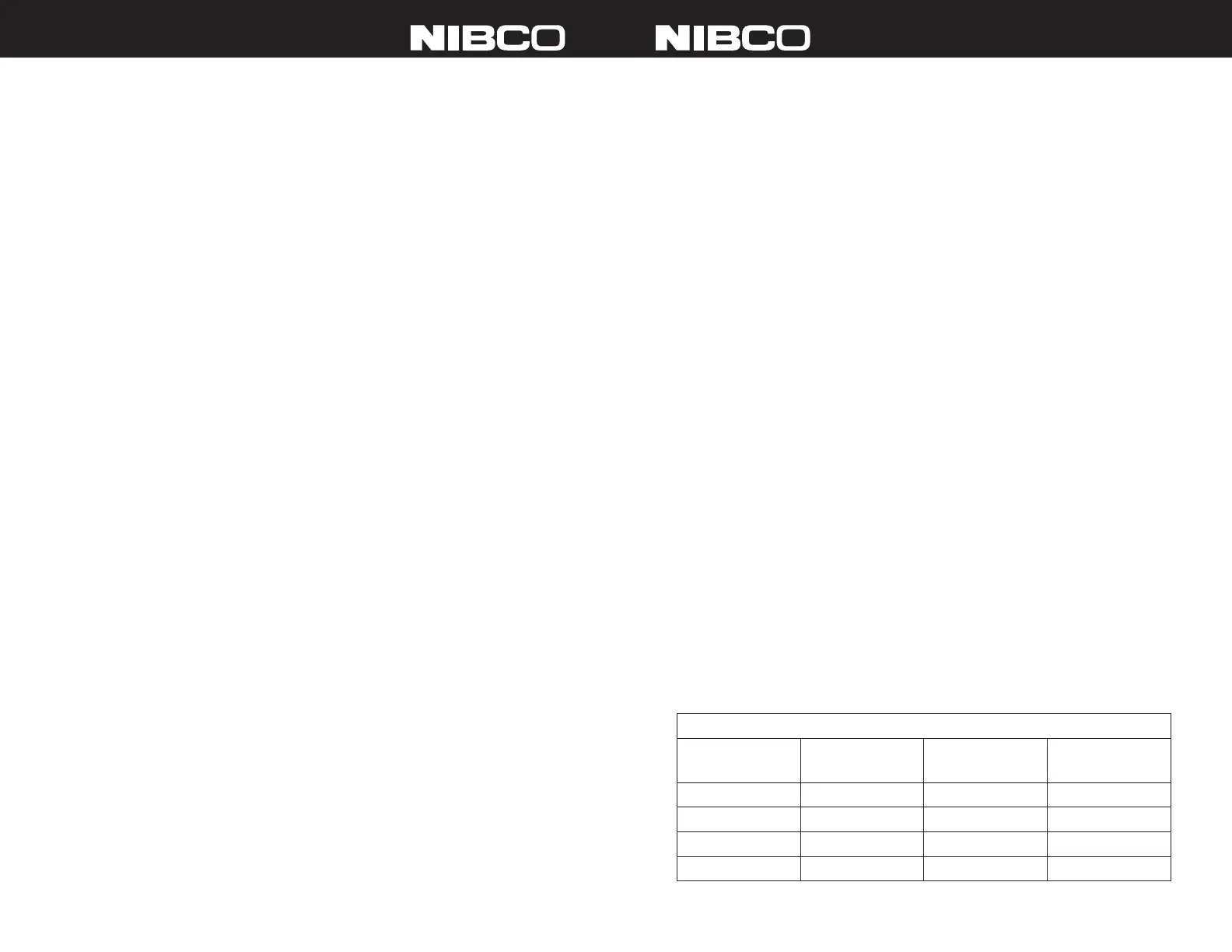

Recommended Fastener Tightening Torques

Flange Size Bolt Size Minimum Bolt

Torque (ft lbs)

Maximum Bolt

Torque (ft lbs)

2” to 4”

5

⁄8”

20 70

5” to 8”

¾”

30 120

10” and 12”

7

⁄8”

50 200

14” and 16”

1”

70 240

Loading...

Loading...