NIBCO INC. WORLD HEADQUARTERS • 1516 MIDDLEBURY ST. • ELKHART, IN 46516-4740 • USA • PH: 1.800.234.0227

TECH SERVICES PH: 1.888.446.4226 • FAX: 1.888.336.4226 • INTERNATIONAL OFFICE PH: +1.574.295.3327 • FAX: +1.574.295.3455

www.nibco.com

6

www.nibco.com

AHEAD OF THE FLOW

®

Crimp Tool Use

The crimp tools supplied with the NIBCO

®

PEX system are high quality instruments designed for heavy-duty use. However, normal use

will require that these tools be adjusted on occasion. Before beginning a job, the installer should conduct a “test” crimp to ensure

that the tool is working properly. If several consecutive joints fail the go /no-go gauge, then the tool may be out of adjustment. During

normal wear conditions, the crimp tool’s crimp diameter tends to increase. NIBCO tools come with instructions for maintaining the tool

and keeping it in proper adjustment. Please follow these instructions.

NIBCO’s 5-Step Method for a Great Crimp Connection

Because NIBCO

®

PEX pipe is extruded to tight tolerances you don’t have to worry about crimp rings sliding or insert fittings falling out

as the system is being “roughed in.” The installer can quickly “hand fit” the system, then go back and crimp each fitting to make the

connection permanent. After crimping, our connections form a reliable and permanent seal. After all connections have been crimped,

the system can be immediately pressure tested. NIBCO crimped connections are immediately permanent whether the installation tem-

perature is hot or cold.

We urge you to thoroughly read the instructions for our 5-step method before beginning any installation.

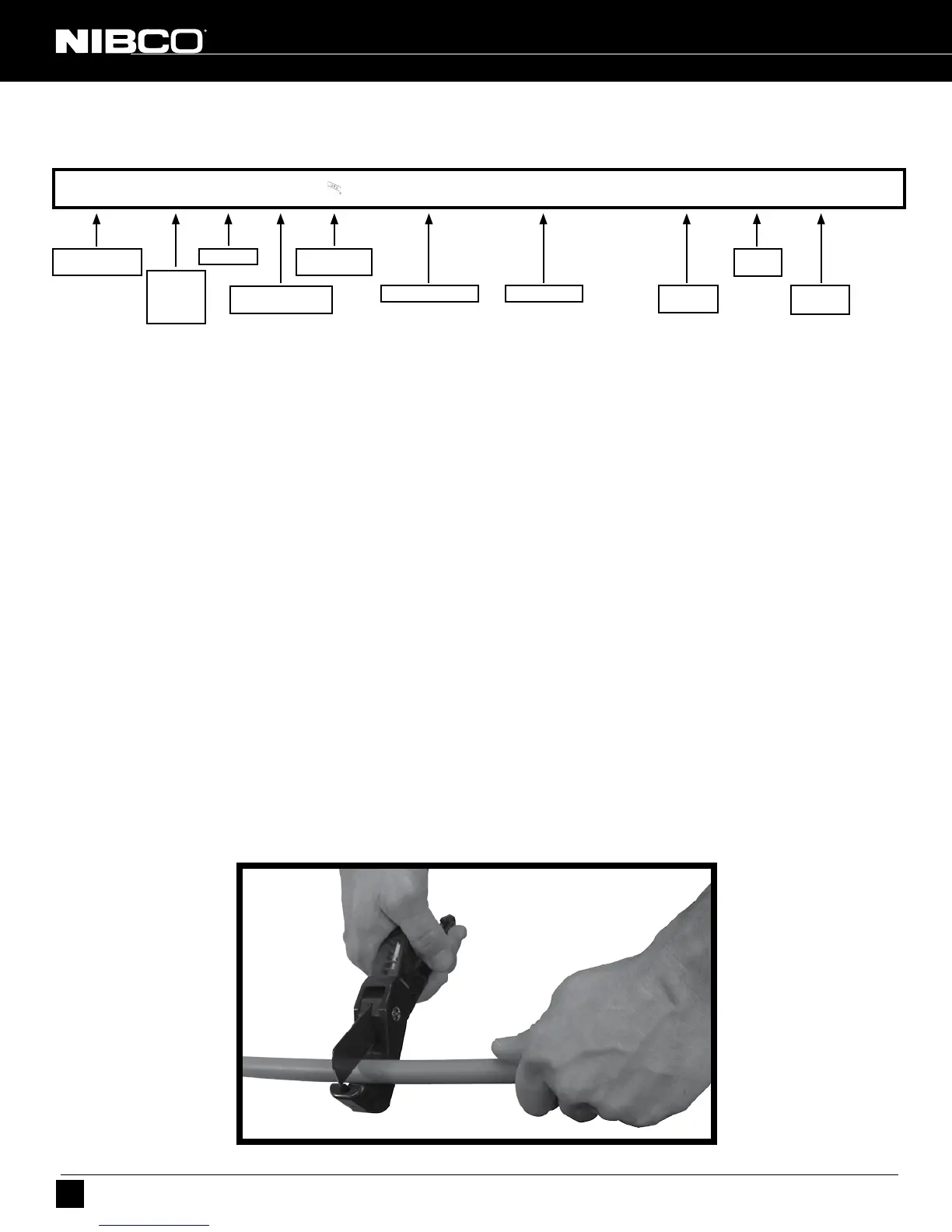

Step 1

Cut the pipe to length squarely. A rough, jagged or irregular cut may result in a failed connection.

Tube Markings

Tubing SizeManufacturer and

Brand

ASTM Specifications

Standard Dimension

Ratio

Pressure Rating Mfg. Date

Code

Footage

Marking

Potable Water

Certifications

Tubing

Material

Designation

Code

Mfg. Lot

Code

NIBCO

®

PEX PEX 3308 (CTS OD) CTS SDR-9 ASTM F876 F877 F1807 F2159 100 psi@180°F CSA B137.5 (date code) (production code) (length) MADE IN USA

160 psi @ 73°F

80 psi @ 200°F

Loading...

Loading...