EB_SV/EV

04 / 2014

Safety- / Relief-Valves are instruments of high quality and should be handled with care. The disc (060) and the seat (001 / 003) are

manufactured out of hardened or tempered steel and are grinded and lapped to give positive sealing. If the valve disc and seat were handled

improper or faulty they will get defect.

Function:

When the pressure before the Safety- / Relief-Valves reaches the set pressure, the valve commences to lift, i.e. open a little at first to discharge

a small amount of medium. If the pressure continues to rise, it will open further and more medium is discharged. At a max. pressure increase of

10% (5%), the stroke required for the mass flow to be discharged is reached. When the pressure drops to 10% (gases / vapours and gases) or

20% (incompressible medium / liquids) below the set pressure, the valve closes and no fluid escapes anymore.

Maintenance:

Safety- / Relief-Valves are designed regarding design and construction in such a way that an optimum of quality is achieved, and that they are

easy to service. A minimum of care and maintenance is the result when our fittings are applied. The maintenance work, however, is permitted to

be carried out only by trained personnel.

We suggest the following:

In and outlets are provided with protective caps. These are to be removed before the installation. The valves may not be thrown

(leakage/failure in operation may result).

The whole system has to be rinsed before installation of the valve! If the plant should not be sufficiently purified or in the case of an

inappropriate assembly, the valve may be leaky already upon first response. The assembly of the threaded valves should be

carried through without using hemp or PTFE-tape. Metal sealing rings are to be preferred.

The Safety- / Relief-Valves have to be fitted vertically with the spindle (080) in an upright position. For a perfect function in the long

run it is also necessary to install the valve without tension into the plant.

In order to prevent the misuse of the lifting lever (head "A") it is binding wire in the closed position. If the mounting is correct and the

pressure is arrived at 85% of the adjusted set pressure the lifting device can be set in motion. The same is valid for lifting heads "B",

"D" and "E": To check the head type "C", the valve should be exposed to response pressure only externally by gas or with a

sufficiently purified plant.

For the valves (particularly) used in steam applies:

Routining the functioning by operating the ventilation at least every 4 weeks.

Foreign substances in the pipeline (such as jointing materials) will seriously damage the seating area of the valve. By operating the

lifting device small deposits of foreign matters can be effectively cleared from the valve disc (060) and seat (001 / 003).

(In doing this, a clear stroke of the valve spindle (080) must be achieved).

The feed nozzle for the valve must be as short as possible and must have at least the same nominal width as the valve.

The pressure loss in the inlet pipe should not exceed 3 % of the set pressure.

The blow-off pipe should be mounted with downward gradient in sufficient dimensioning. Resulting condensate must be exhausted

safely. Inside the blow-off pipe the backpressure of max. 10 % of the set pressure should not be exceeded.

The operating pressure of the plant should be at least 5% below the closing pressure of the valve (pressure peaks in case of piston

pumps must be taken into consideration!). Thus a perfect closing of the valve after blow-off is ensured.

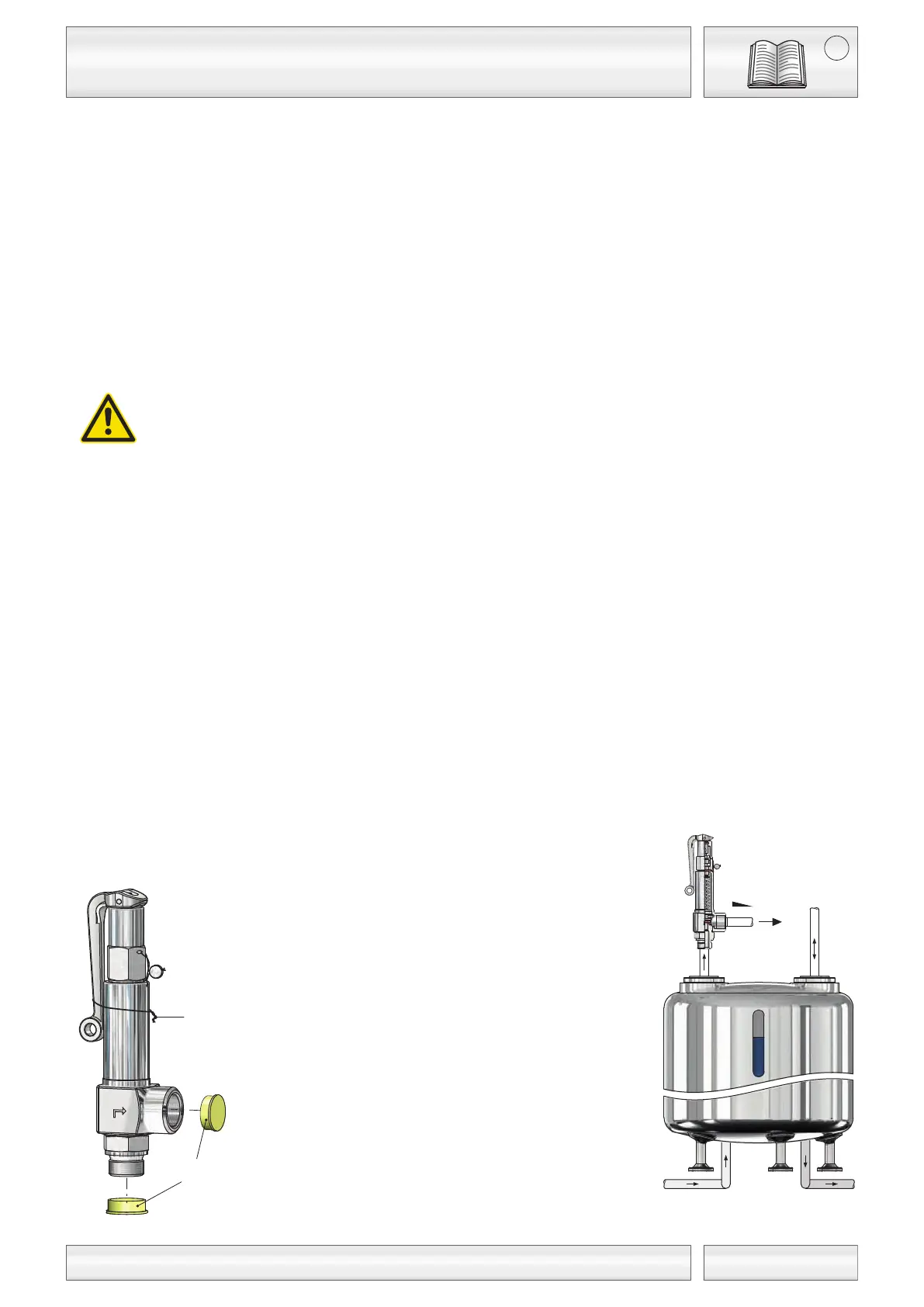

binding wire

protective caps

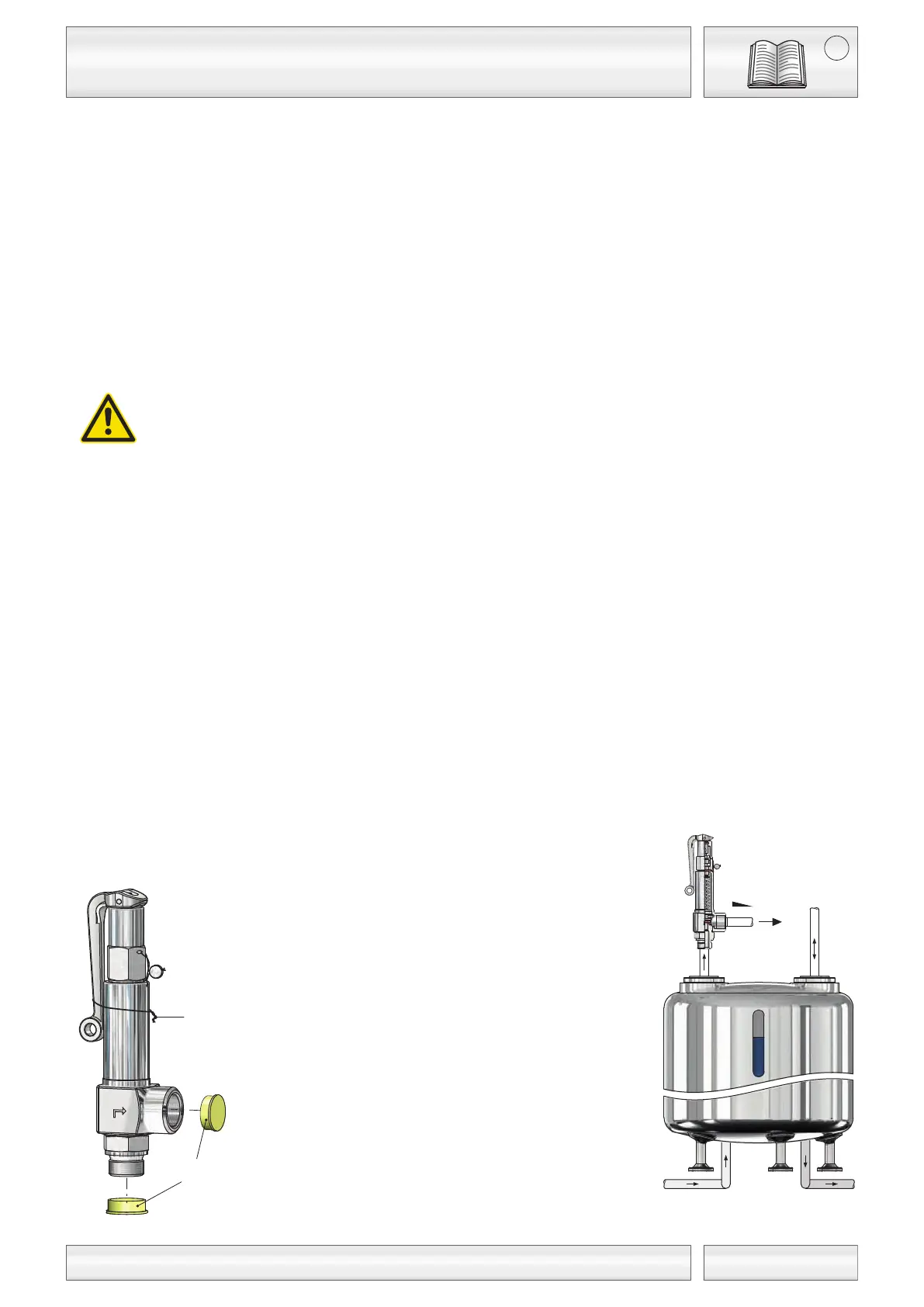

filling line emptying line

Loading...

Loading...