EN EN

6

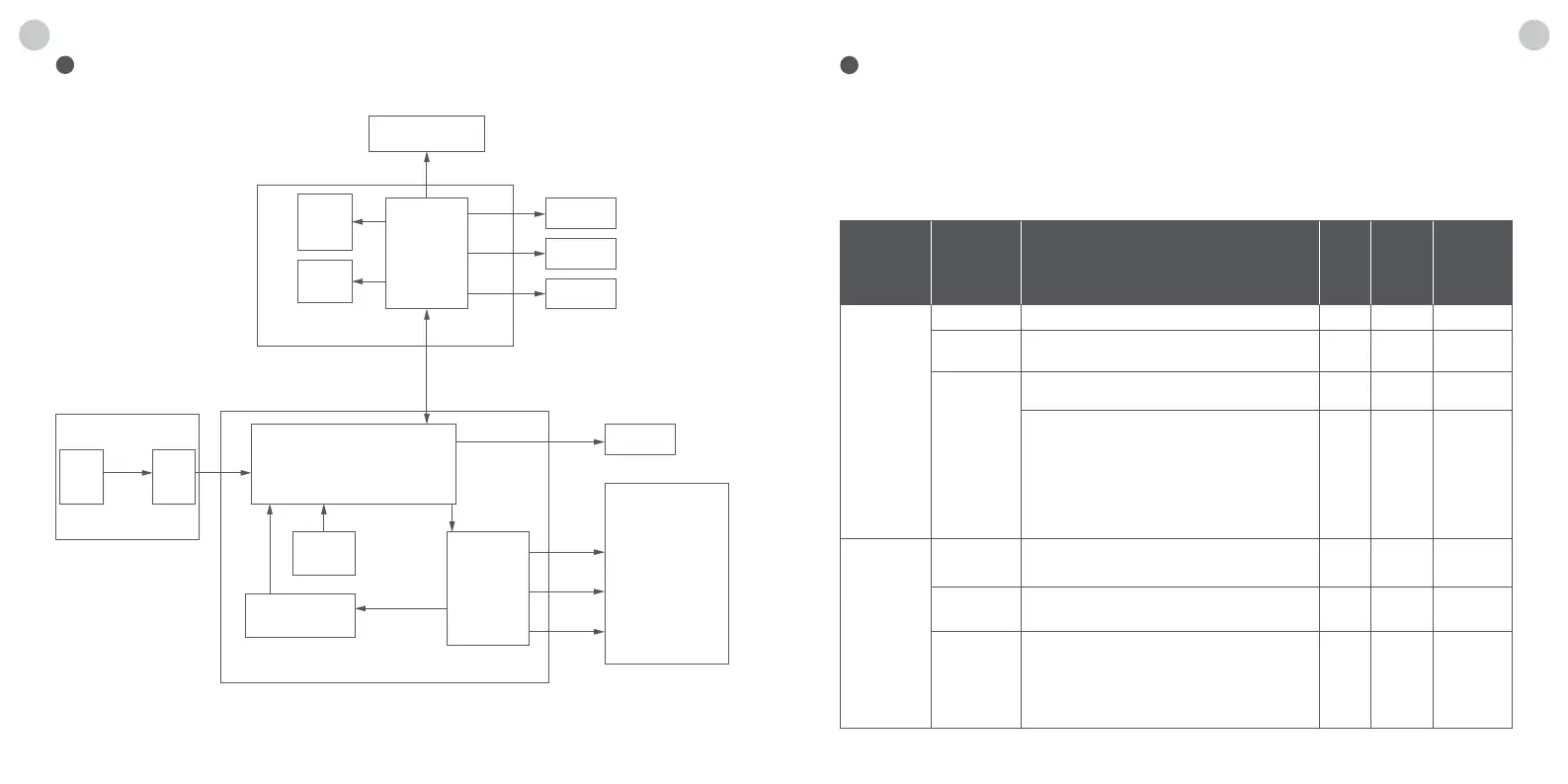

Wiring Diagram

Controller

Motor

Dashboard

Throttle

Brake

Headlight

MCU

Buzzer

Display

Bluetooth

Module

U

V

W

Motor driver

Battery

BMSCell

Voltage

Sampling

Current

Sampling

Tail light

Direction Indicator

* For 051401D only

7

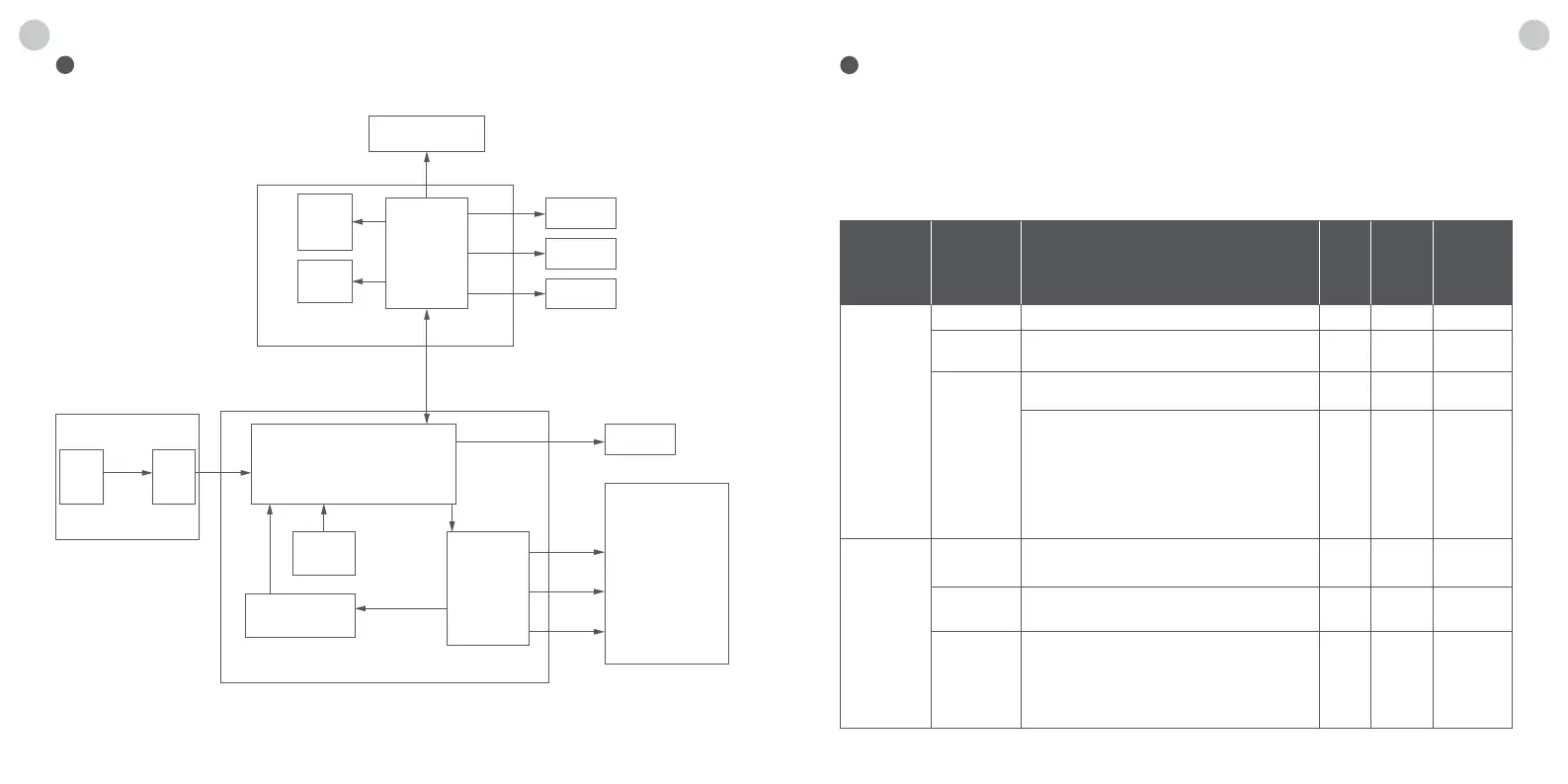

Recommended Maintenance Schedule

To ensure safe riding, day to day care and regular maintenance are essential. You, the owner, havecontrolandknowledgeof

howoftenyouuseyourscooter,howhardyouuseitandwhereyouuseit. It is the owner's responsibility to perform regular checks

and bring your scooter to authorized service center for inspection and service. Please refer to the maintenance schedule

below.

Note: This maintenance schedule charges a service fee.

Item Component

Mainframe parts Use a soft, wet cloth to wipe the mainframe clean.

Tire wear

Screws on the

stem top

Mainframe

maintenance

Check if the tires are cracked, deformed, or

significantly worn.

Tighten the six screws fixed with the handlebar and the

stem. The suggested torque is 5.5±0.3 N·m.

Tighten the screw on the throttle. The suggested

torque is 2±0.1 N·m.

Tighten the screws on the brake levers. The suggested

torque is 5±0.1 N·m.

Tighten the screws on the stem top. The suggested

torque is 2±0.1 N·m.

Maintenance Method

Every 3

months

Every 6

months or

every 310

miles (500

km)

After 2 years or

the total

mileage > 3107

miles (5000

km)

√√

√√

√√√

√√√

Hub motor

Rear wheel

maintenance

Drum Brake

To accelerate and decelerate, check if the hub motor is

stalled or has abnormal sounds.

Check if the rear wheel is stalled or gets shaky, or the axis

shaft is unbalanced.

1) Spin the rear wheel, it spins normally. The rear wheel

shall not stuck or make abnormal sounds.

Note: Slight noise does not affect riding safety. But if the

drum brake makes a loud noise when you apply brakes,

please contact customer service for support.

2) Squeeze the brake lever, the rear wheel stops moving.

√√

√√

√√

Function

Inspection

09 10

Loading...

Loading...