CHAPTER Two: Installation Instructions

WARNING This product should be installed and serviced only by a qualified professional.

1.

Pump Location

DO NOT install pump in a damp or non-ventilated location.

Keep motor clean. Pump motor requires free circulation of air for cooling.

2.

Pump Mounting

Install pump on a firm, level base or pad to meet all local and national codes. Fasten pump to base or pad with screws or

bolts to further reduce vibration and stress on pipe or hose joints. The base MUST be solid, level, rigid, and vibration

free.

Pump mount must:

- Allow pump inlet height to be as close to water level as possible.

- Allow use of short, direct suction pipe (to reduce friction losses).

- Allow for gate valves in suction and discharge piping.

- Be protected from excess moisture and flooding. Allow adequate access for servicing pump and piping.-

- Make sure suction joints are tight. Suction pipe should be as large or larger than discharge pipe.

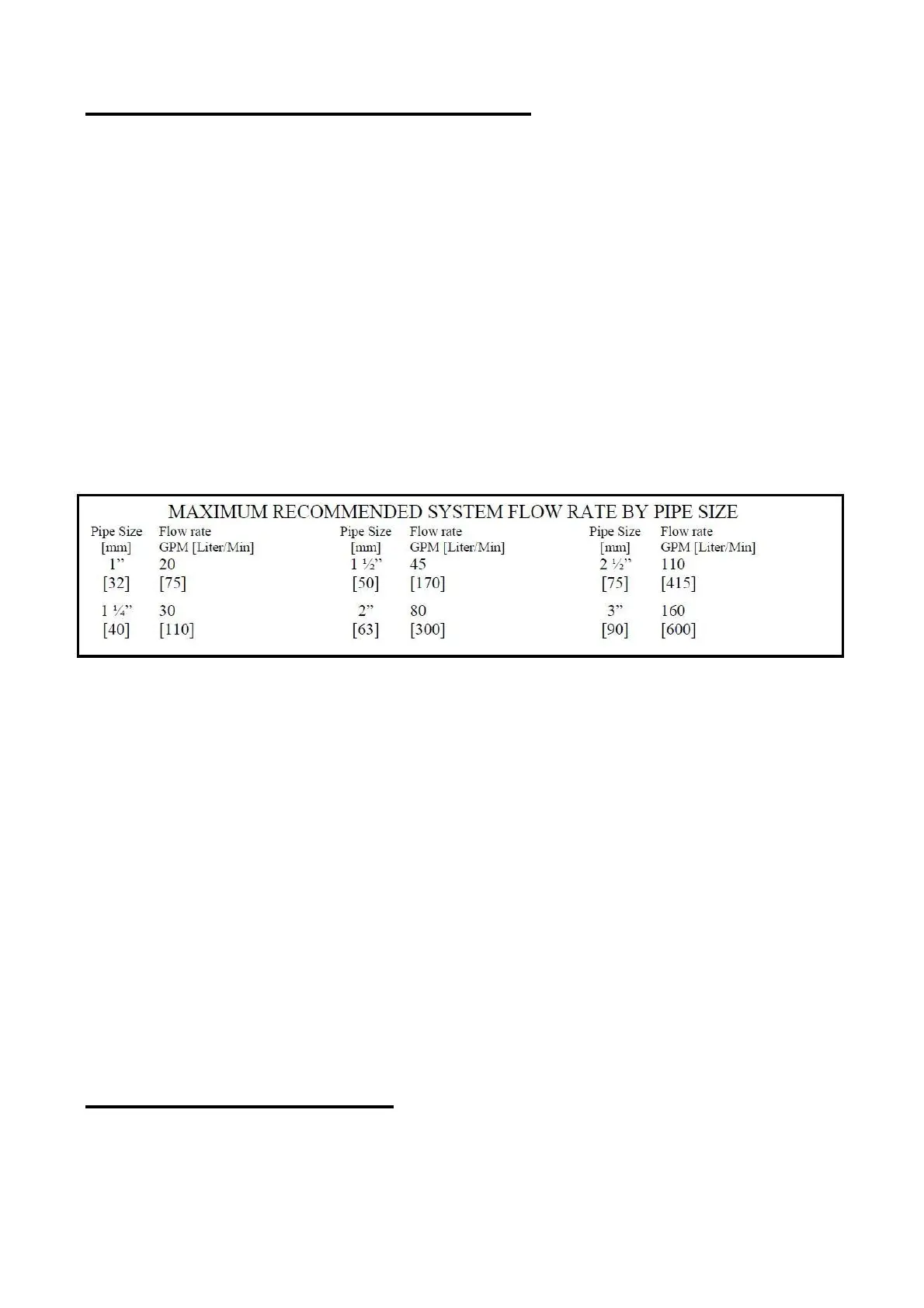

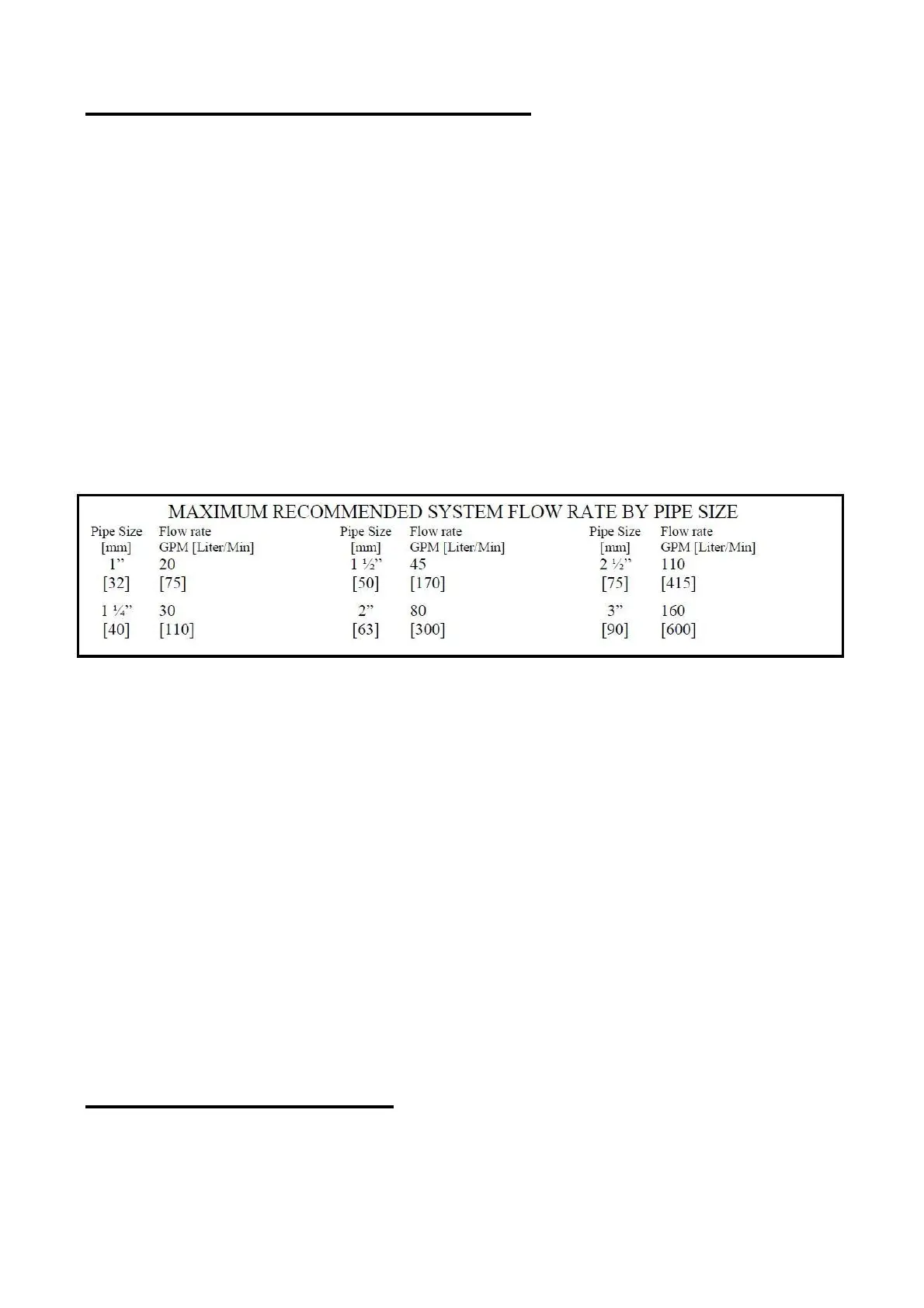

Pipe Sizing Chart

WARNING Hazardous Pressure.

Pumps, filters, and other equipment/ components of a swimming pool filtration system operate under pressure.

Incorrectly installed and/or improperly tested filtration equipment and/or components may fail resulting in injury

and/or property damage.

3.

Plumbing

Use Teflon tape to seal threaded connections on molded plastic components. All plastic fittings must be new or

thoroughly cleaned before use. NOTE - Do NOT use Plumber’s Pipe Dope as it may cause cracking of the plastic

components. When applying Teflon tape to plastic threads, wrap the entire threaded portion of the male fitting with

one to two layers of tape. Wind the tape clockwise as you face the open end of the fitting, beginning at the end of the

fitting. The pump suction and outlet ports have molded-in thread stops. Do NOT attempt to force hose connector

fitting past this stop. It is only necessary to tighten fittings enough to prevent leakage. Tighten fitting by hand and

then use a tool to engage fitting an additional 1 ½ turns. Use care when using Teflon tape as friction is reduced

considerably; do NOT over-tighten fitting or you may cause damage. If leaks occur, remove connector, clean off

old Teflon tape, re-wrap with one to two additional layers of Teflon tape, and re-install connector.

4.

Fittings

Fittings restrict flow. For better efficiency, use the fewest possible fittings (but at least two suction outlets). Avoid

fittings that could cause an air trap. Pool fittings MUST conform to the International Association of Plumbing and

Mechanical Officials (IAPMO) standards. Use a non-entrapping suction fitting in pool (multiple drains) or double

suction (skimmer and main drain).

CHAPTER Three: Electrical

1.

Ground and bond motor before connecting to electrical power supply. Failure to ground and bond pump motor can

cause serious or fatal electrical shock hazard.

2.

Do NOT ground to a gas supply line.

3.

To avoid dangerous or fatal electrical shock, turn OFF power to motor before working on electrical connections.

4.

Ground Fault Circuit Interrupter (GFCI) tripping indicates electrical problem. If GFCI trips and won’t reset,

Loading...

Loading...