T201806EN

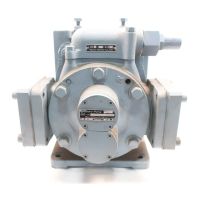

Trochoid Pump

Lunary Pump

Instruction Manual

Read this manual thoroughly and carefully before installing or selecting a

pump.

Follow all instructions carefully to ensure the correct and efficient pump

installation and operation.

This manual contains suggestions and instructions on pump selection,

installation, operation, and troubleshooting.

Failure to observe this manual prior to operation may result in personal

injury and/or equipment damage.

Important

Store this manual in a safe and readily accessible

location for future references