REDUCTION BELT TENSIONING

Reduction belt should not have more free play than 5 mm, but not lower than

2 mm.

Loose the shaft nut (by special key supplied in the set), set the correct tension of

the belt by the upper screw and tighten fast the shaft nut.

PROPELLER ORIENTATION SETTING

Set propeller to vertical position. Find the distance between the blade end and the

frame with some tool (e.g. screwdriver). Then rotate the prop by 180

o

and check

whether the distance is the same on the other blade. If there is a difference, loose

firstly propeller screw on the less deflected side and than tighten both.

PROPELER MAINTENANCE

Always store the propeller in a dry place. Do not expose it to sudden temperature

changes. Store it in horizontal position. Do not expose the propeller unnecessarily

to sunshine.

Check the propeller after each flight. If it has small scratches, it is necessary to

repair them to prevent any dampness penetration. You can make Small repairs

yourself using special tools and solutions. It is necessary to balance the propeller

after every repair.

It is recommended to have the propeller generally treated and balanced after some

time.

Any unprofessional treatment of the propeller can have fatal consequences

(misbalance, high vibrations, loosing the prop in flight, frame destruction, reduction

damage,…)

CHARGING THE BATTERY

See detailed description in “Charger ICS 1702 manual”

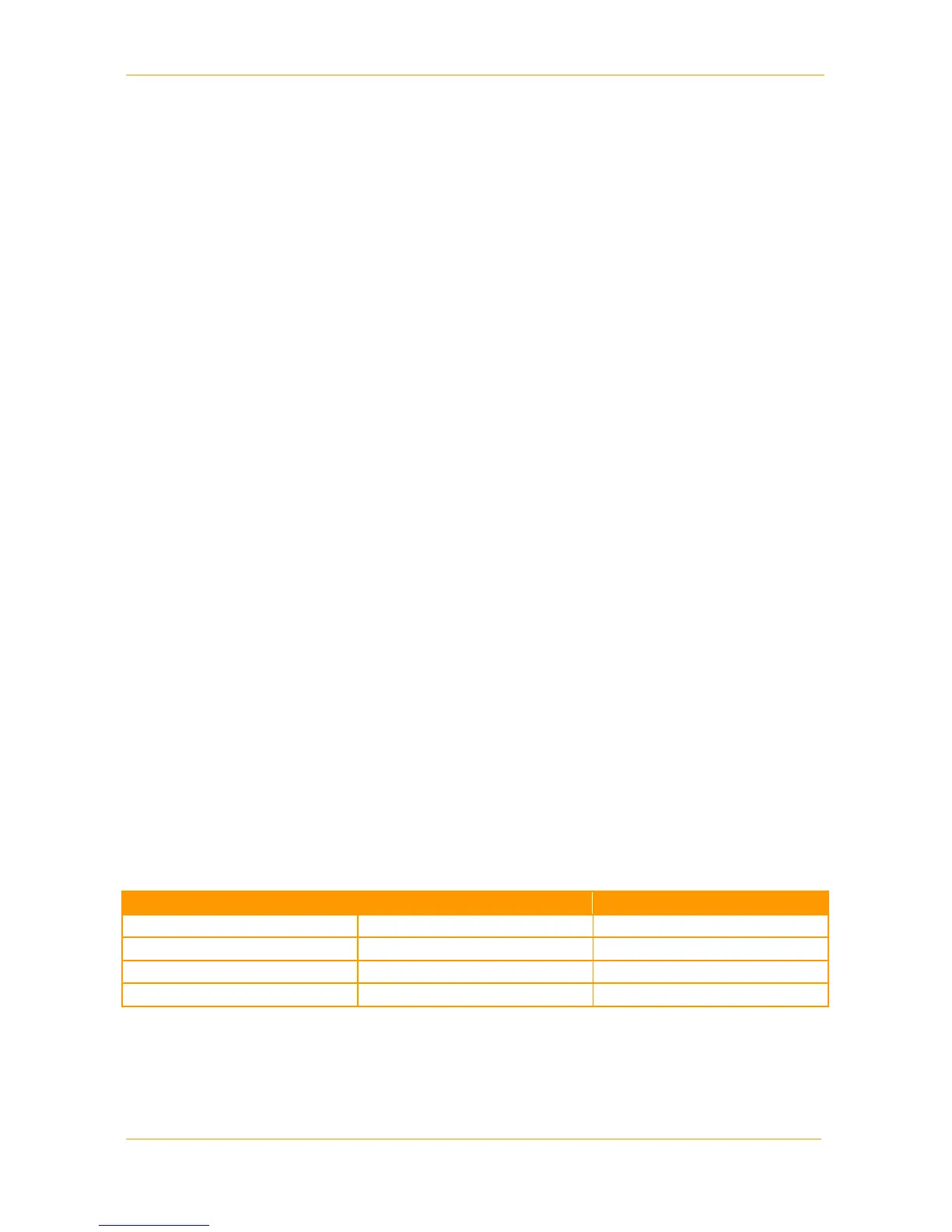

REGULAR MAINTENANCE

part check replacement

spark-plug 10 h 50 h / 1 year

reduction belt before each flight 100 h / 2 years

engine silentblocks before each flight 100 h / 2 years

exhaust silentblocks before each flight 100 h / 2 years

In case of evident damage of any part of the paramotor it is necessary to repair or replace it

before first next flight.

Loading...

Loading...