ENGINE UNIT

EM-111

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

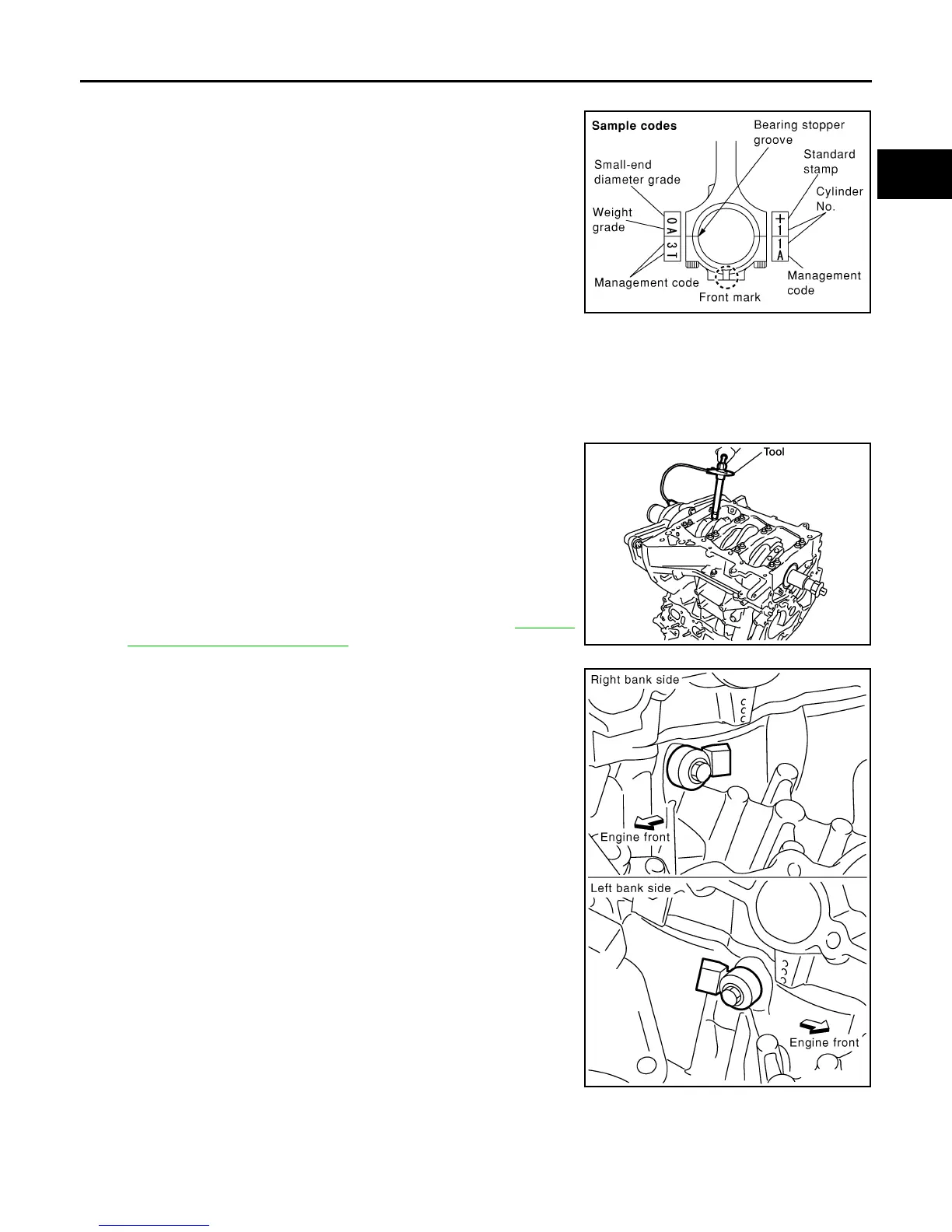

17. Install connecting rod bearing cap.

• Match the stamped cylinder number marks on connecting rod

with those on connecting rod bearing cap to install.

• Be sure that front mark on connecting rod bearing cap is fac-

ing front of engine.

18. Tighten connecting rod bolts in two steps as follows:

a. Apply engine oil to the threads and seats of connecting rod bolts. Tighten the connecting rod bolts to spec-

ification

b. Then tighten (turning clockwise) all connecting rod bolts 90°

using Tool.

CAUTION:

Always use Tool. Avoid tightening based on visual check

alone.

• After tightening connecting rod bolts, make sure that crank-

shaft rotates smoothly.

• Check the connecting rod side clearance. Refer to EM-112,

"Inspection After Disassembly".

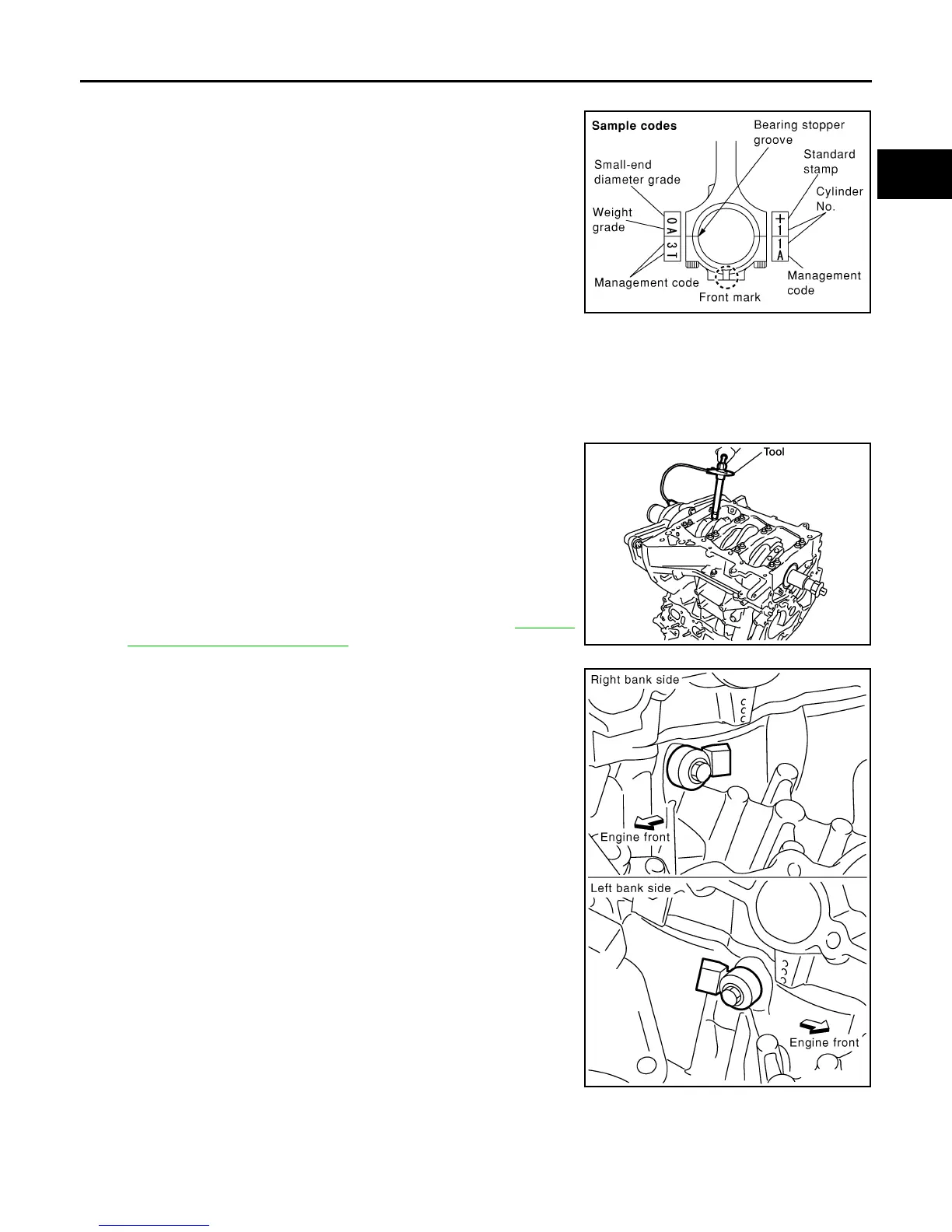

19. Install knock sensors.

• Install knock sensor so that harness connector faces rear of

engine.

• After installing knock sensor, connect harness connector, and

lay it out to rear of engine.

CAUTION:

• Do not tighten bolts while holding harness connector.

• If knock sensor is dropped, replace it with new one.

NOTE:

• Make sure that there is no foreign material on the cylinder

block mating surface and the back surface of knock sensor.

• Make sure that knock sensor does not interfere with other

parts.

20. Assembly is in the reverse order of disassembly after this step.

Flywheel (M/T models)

• Install flywheel.

PBIC0809E

Connecting rod bolt : 19.6 N·m (2.0 kg-m, 14 ft-lb)

Tool number : KV10112100 (BT-8653-A)

WBIA0586E

Knock sensor bolts : 18.1 N·m (1.8 kg-m, 13 ft-lb)

PBIC2948E

Revision: January 2013 2013 Xterra

Loading...

Loading...