CAMSHAFT

EM-83

< REMOVAL AND INSTALLATION >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

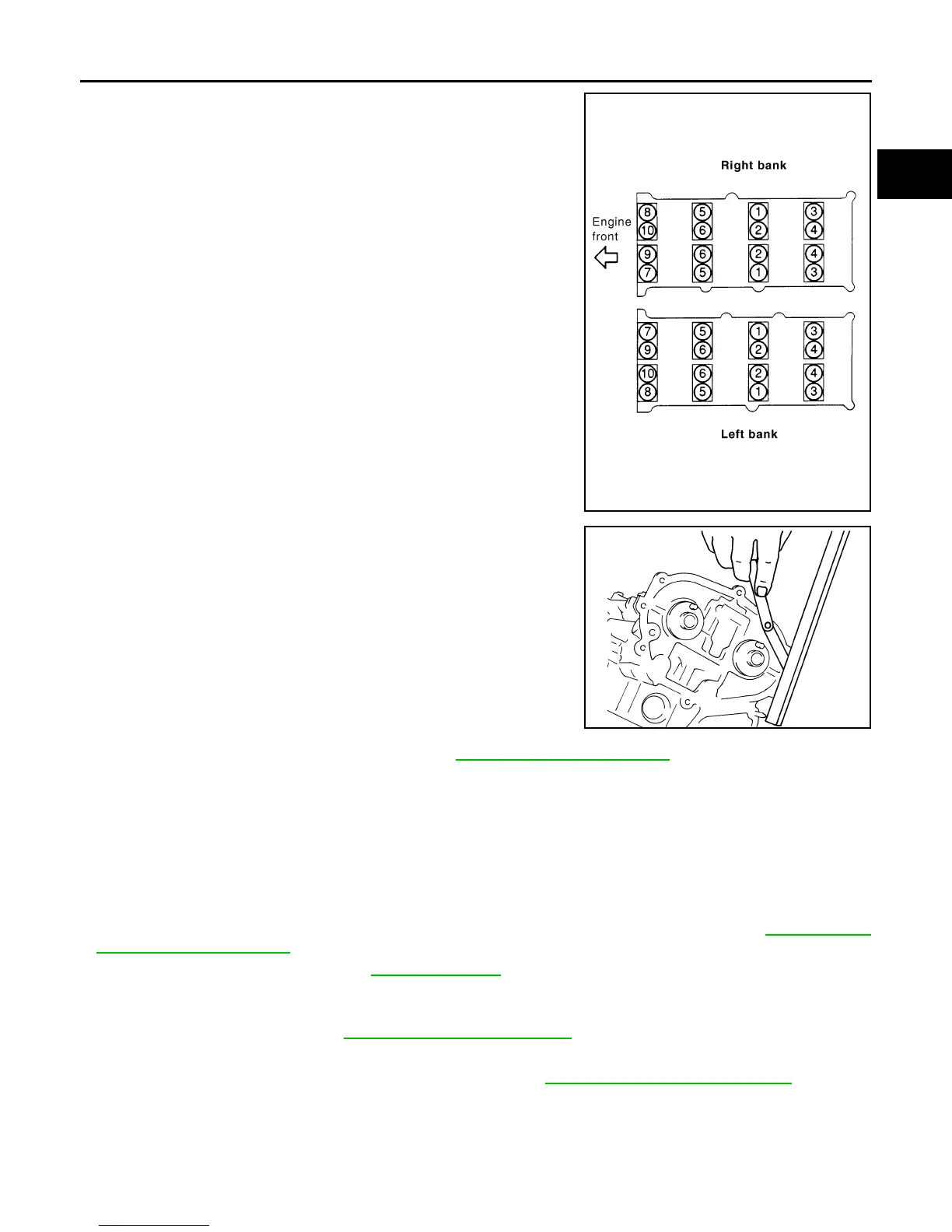

5. Tighten camshaft bracket bolts in the following steps, in numeri-

cal order as shown.

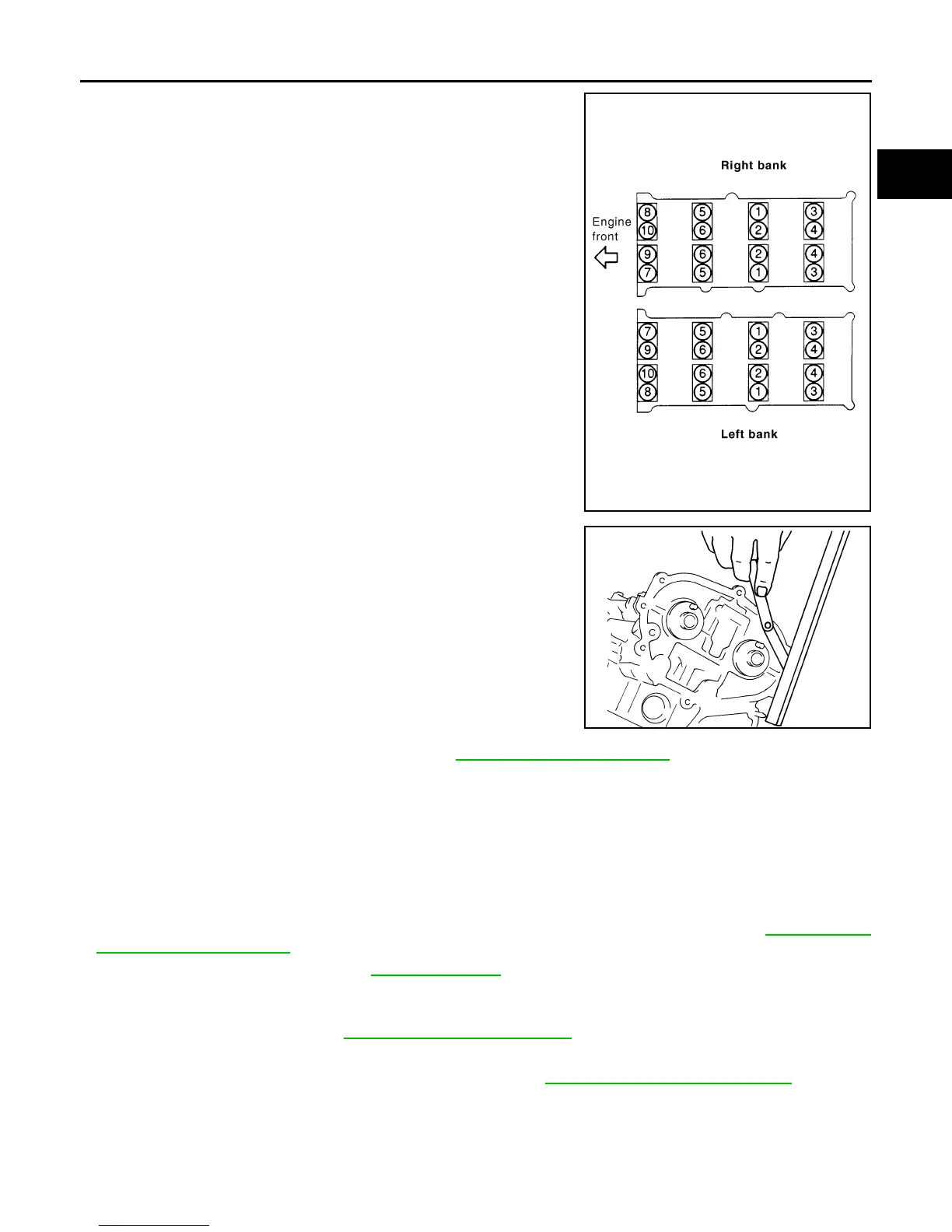

6. Measure the difference in levels between front end faces of

camshaft bracket (No. 1) and cylinder head.

• Measure two positions (both intake and exhaust side) for a

single bank.

• If the measured value is out of the standard, re-install cam-

shaft bracket (No. 1).

7. Check and adjust the valve clearance. Refer to EM-129, "Standard and Limit"

.

8. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT) Oil Groove

WARNING:

• Check when engine is cold so as to prevent burns from any splashing engine oil.

CAUTION:

• Perform this inspection only when DTC P0011 or P0021 are detected in self-diagnostic results of

CONSULT and it is directed according to inspection procedure of EC section. Refer to EC-174, "DTC

Confirmation Procedure".

1. Check the engine oil level. Refer to LU-7, "Inspection"

.

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release fuel pressure. Refer to EC-491, "Fuel Pressure Check"

.

b. Disconnect the harness connectors from ignition coil and injector.

3. Remove intake valve timing control solenoid valve. Refer to EM-51, "Removal and Installation"

.

Camshaft bracket bolts

Step 1 (bolts 7 - 10) : 1.96 N·m (0.2 kg-m, 17 in-lb)

Step 2 (bolts 1 - 6) : 1.96 N·m (0.2 kg-m, 17 in-lb)

Step 3 (bolts 1 - 10) : 5.88 N·m (0.6 kg-m, 52 in-lb)

Step 4 (bolts 1 - 10) : 10.4 N·m (1.1 kg-m, 92 in-lb)

PBIC2050E

Standard : –0.14 to 0.14 mm (–0.0055 to 0.0055 in)

EMQ0044D

Revision: January 2013 2013 Xterra

Loading...

Loading...