Revision 6

Installing Suction

or

Discharge Manifolds:

13. Wipe clean, with lint-free rags, all mating surfaces.

Place the suction and discharge

manifolds into their proper locations. The design

of

the mounting bolt holes, size, and

valve porting insures correct component alignment only. Hand start the manifold bolts.

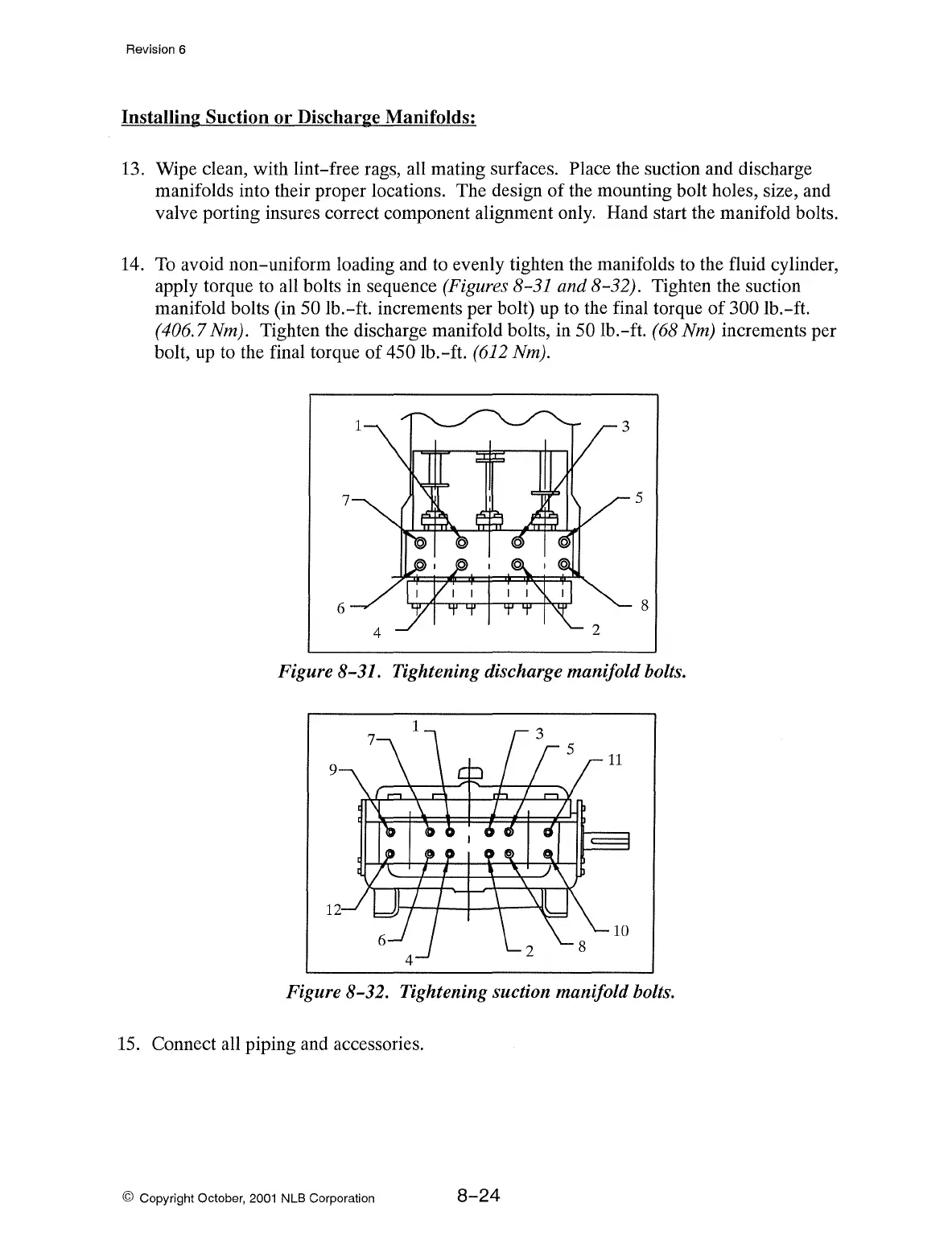

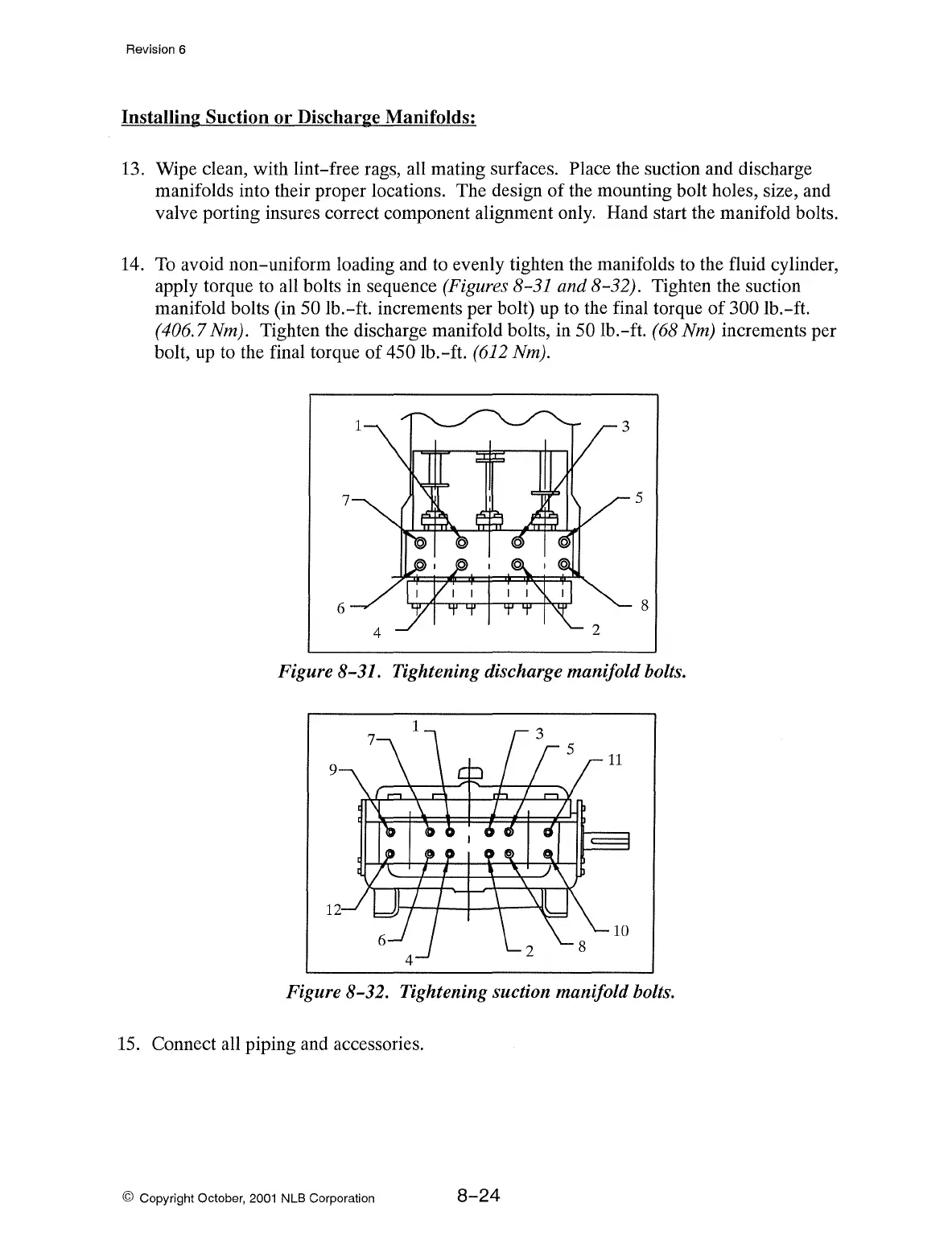

14.

To

avoid non-uniform loading and to evenly tighten the manifolds to the fluid cylinder,

apply torque to all bolts in sequence

(Figures 8-31 and 8-32). Tighten the suction

manifold bolts (in

50 lb.-ft. increments per bolt) up

to

the final torque

of

300 lb.-ft.

(406. 7 Nm). Tighten the discharge manifold bolts, in 50 lb.-ft. (68 Nm) increments per

bolt, up to the final torque

of

450 lb.-ft. (612 Nm).

7

5

6

8

Figure 8-31. Tightening discharge manifold bolts.

Figure 8-32. Tightening suction manifold bolts.

15.

Connect all piping and accessories.

© Copyright October,

2001

NLB Corporation

8-24

Loading...

Loading...