ASSEMBLY

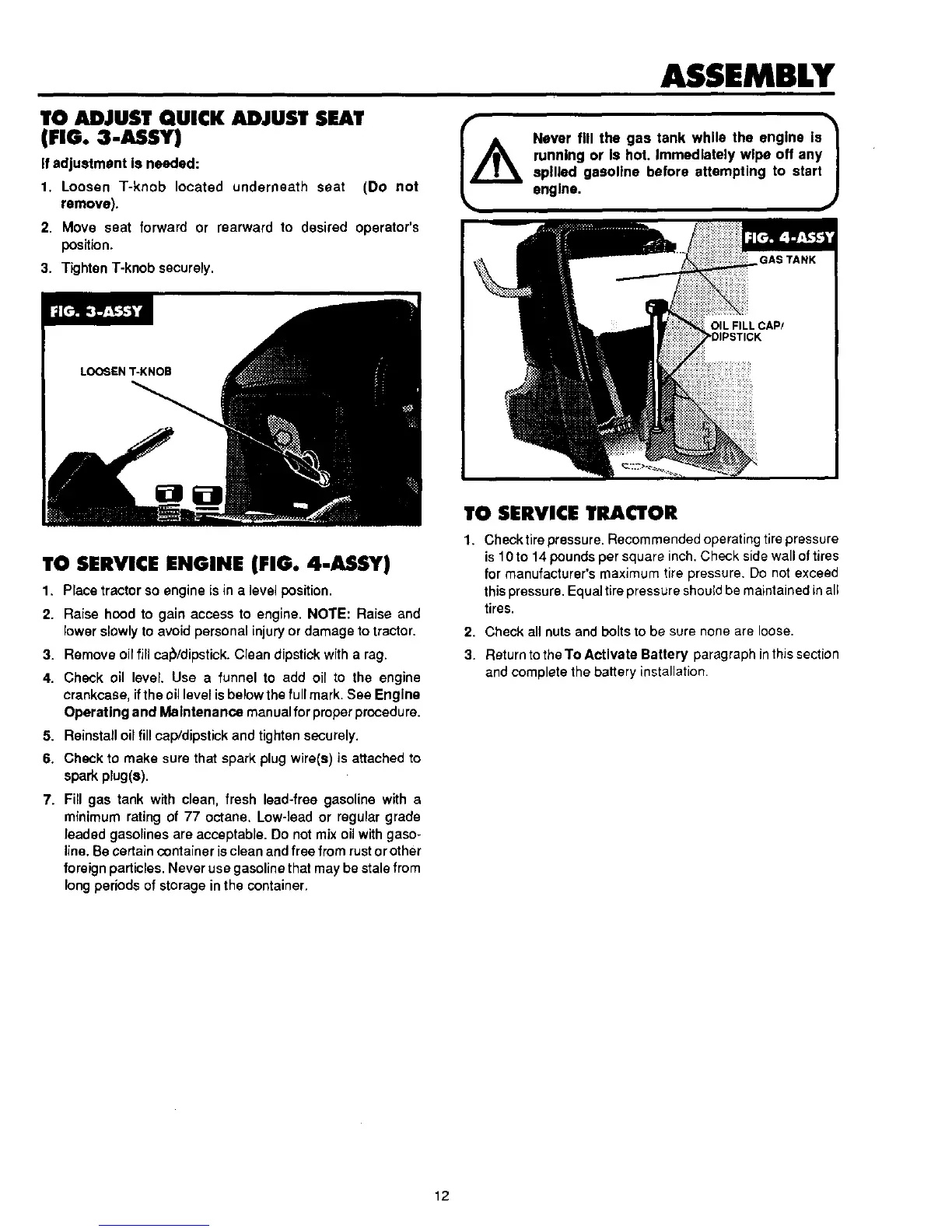

TO ADJUST QUICK ADJUST SEAT

(FIG.3-ASSY!

if adjustment Is needed:

1. Loosen T-knob located underneath seat (Do not

remove).

2, Move seat forward or rearward to desired operator's

position.

3. T_ghtenT-knob securely.

I_ Never fill the gas tank while the engine is |

running or Is hot. Immediately wipe off any |

spilled gasoline before attempting to start |

engine. J

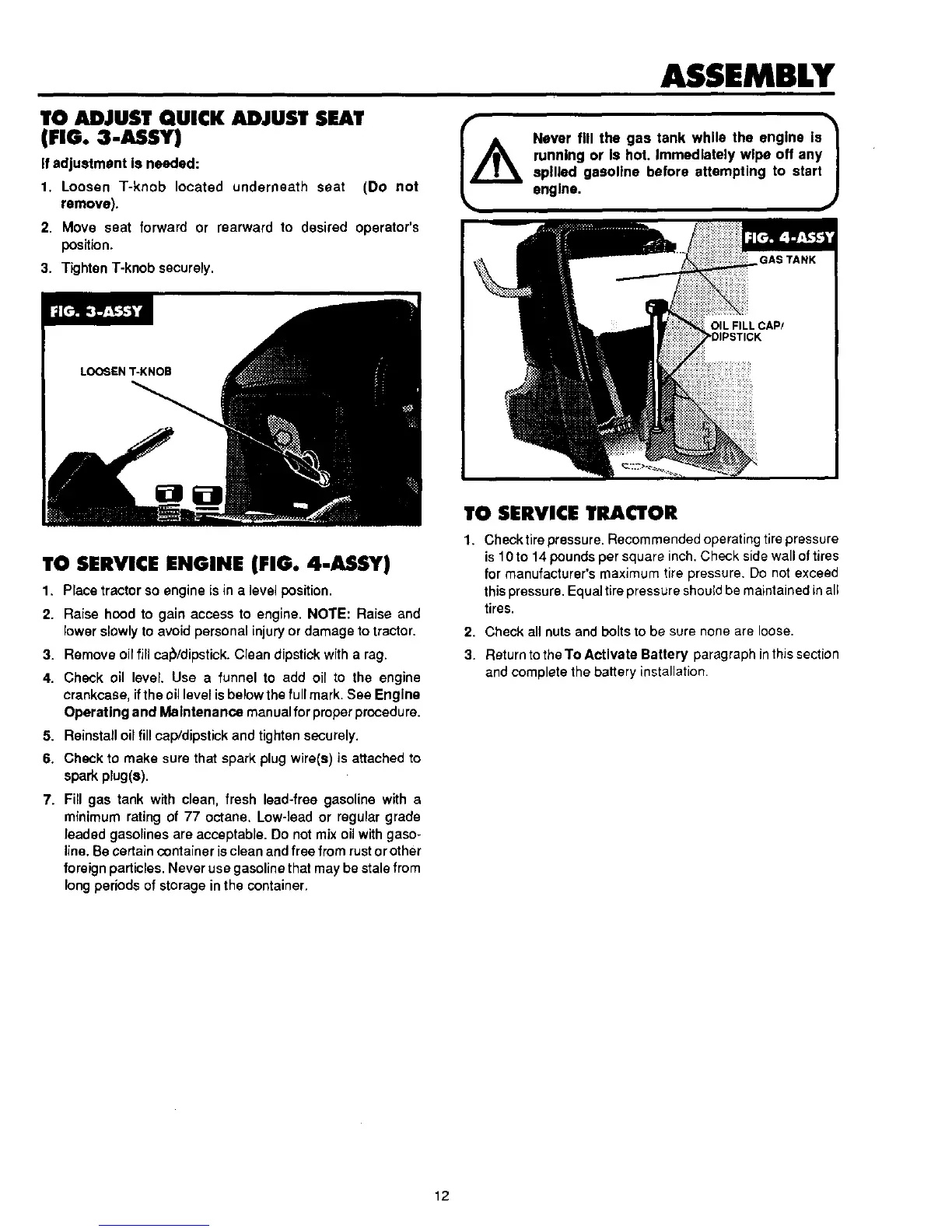

TO SERVICE ENGINE (FIG. 4-ASSY)

1. Place tractor so engine is in a level position.

2. Raise hood to gain access to engine. NOTE: Raise and

lower slowly to avoid personal injury or damage to tractor.

3. Remove oir fill cal'/dipstick. Clean dipstick with a rag.

4. Check oil level. Use a funnel to add oil to the engine

crankcase, if the oil level is below the full mark. See Engine

Operating and Maintenance manual for proper prooedu re.

5. Reinstall oil fill cap/dipstick and tighten securely.

6. Checkto make sure that spark plugwire(s)is attachedto

spark plug(s).

7. Fill gas tank with clean, fresh lead-free gasoline with a

minimum rating of 77 octane. Low-lead or regular grade

leaded gasolines are acceptable. Do not mix oil with gaso-

line, Be certain container isclean and free from rust or other

foreign particles. Never use gasoline that may be stale from

long periods of storage in the container.

TO SERVICE TRACTOR

1. Check tire pressure. Recommended operating tire pressure

is 10 to 14 pounds per square inch. Check side wall of tires

for manufacturer's maximum tire pressure. Do not exceed

this pressure. Equal tire pressure shoutd be maintained in all

tires,

2. Check all nuts and bolts to be sure none are loose.

3. ReturntotheToActivateBattery paragraphinthissection

and complete the battery installation.

12

Loading...

Loading...