31

Condensate Piping

Chapter4.–Installation

4-8. Condensate Piping

• This Combi Boiler is a high efciency, fully condensing appliance which produces acidic condensate during operation. The Combi Boiler

incorporates a collection and removal system which must be properly drained in order to ensure proper operation of this appliance.

• The pH level of the condensate is approximately 2-3. An external neutralizer must be installed on the drain piping prior to disposal when

required by local code or when the condensate could cause damage.

• If an external neutralizer is installed, periodic replacement of the neutralizing agent will be required. Refer to the instructions supplied

with the neutralizer for suggested replacement intervals.

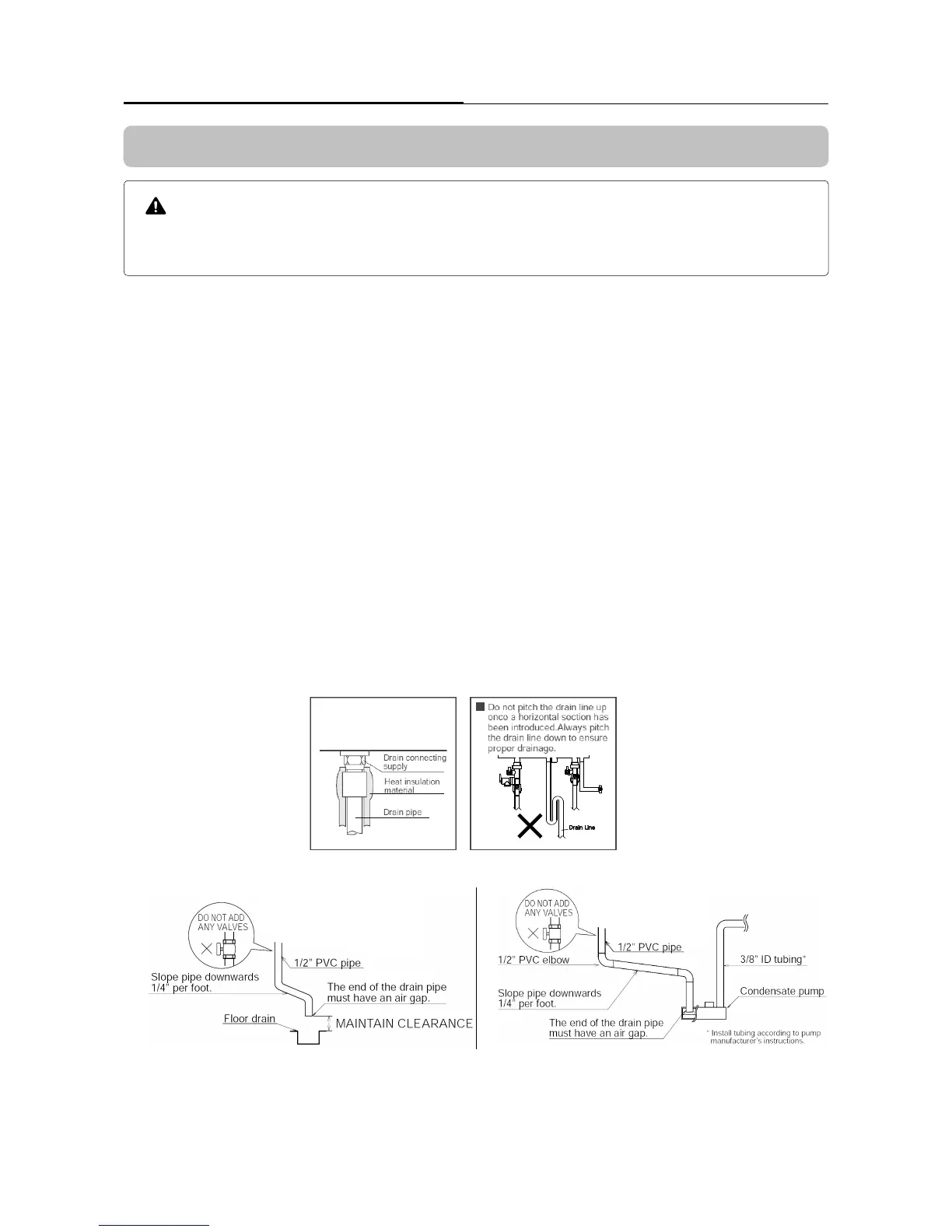

• In order to drain the condensate, a 1/2" threaded tting is provided at the base of the Combi Boiler. Do not reduce the size of this tting

or the drain piping to less than 1/2". In cold climates, do not drain the condensate to the outdoors. If the drain pipe freezes during cold

weather, the pipe will not drain condensate and the unit will stop operating.

• Use plastic pipe, such as PVC, for the drain line. Do not use steel, black iron, or any other material which can corrode when placed into

contact with acidic condensate.

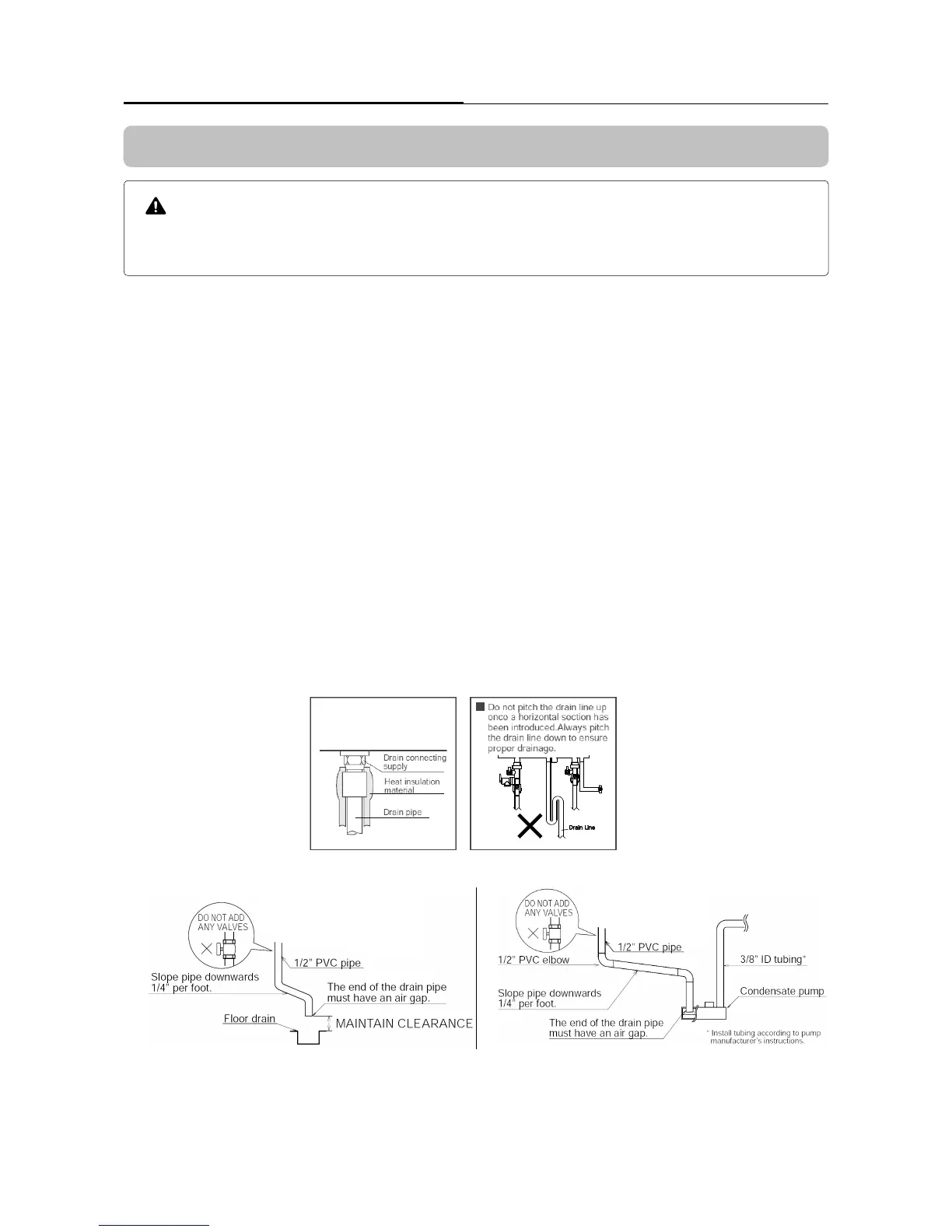

• Keep the length of the drain pipe as short as possible. Long runs or applications where the nearest drain is above the Combi Boiler will

require the use of a condensate pump. Size the pump to allow for a maximum condensate discharge of 2 GPH from the Combi Boiler.

• Horizontal runs must be sloped 1/4" per foot towards the drain or condensate pump. The condensate will be discharged by gravity force

only. Make the drain pipe run as short as possible.

• The end of the drain pipe must not be submerged in water or blocked in any way. To ensure proper drainage, leave the end of the drain

pipe open to the atmosphere. Do not have a trap. Also, make sure that there are no obstructions blocking the drain line from discharging

condensate.

• Be sure to check that condensate is freely owing from the drain piping after the system has been installed. Condensate will begin ow-

ing out of the Combi Boiler within 15 minutes after operation has started.

• Take measures to prevent the condensate drain lines from freezing (insulation, heat tape, electric heaters, etc.).

• The bottom of the Combi Boiler must be higher than the top of the laundry tub to use this option. The condensate drain pipe must have

a negative slope to drain properly.

Due to the acidic nature of the condensate, be sure to properly drain and if necessary, treat the condensate

prior to disposal. Damage caused by improperly handled condensate is not covered by the warranty.

CAUTION

Note:

If the drain line becomes clogged or frozen, condensate will back-up into the Combi Boiler and a "29" error code will ash on the

display window, ceasing operation. If this occurs, clear the clog or freeze so that condensate can freely ow. Be sure to slope the

drain pipe, use the appropriate size pipe, allow the proper clearances, and apply freeze prevention measures (when necessary) to

prevent the drain line from clogging or freezing..

Condensate piping to oor drain

Condensate piping with pump

Combi Boiler

Loading...

Loading...