29

GB

COMPONENTS AND CONTROLS (PIC.1)

FITTING THE RIVING KNIFE. (PIC. 2)

Tofittherivingknife,removethetableinsert.(Pic. 1) 16.With

the table insert removed the two rivingknife securing socket

screws can be seen (Pic. 2). Using asuitablesizedhex key

slacken the two socket screws, locate the riving knife and

securewiththetwosocketscrews.See for the

correctsettingoftherivingknife.

FITTING THE BLADE GUARD. (PIC. 3)

The blade guard (Pic.1)8isattachedtotherivingknife.Remove

the nylok nut and washer from the guard securing coach bolt

and remove the guard securing coach bolt from the blade

guard.Locatethebladeguardovertherivingknife,reinsertthe

guard securing coach bolt and refit the nylok nut and washer

(Pic.3).Checktheoperationofthebladeguardensuringthatit

iscorrectlyfittedandoperatesfreely.

MOUNTING THE ELEVATING HANDLE (PIC. 4)

The elevating screw is located at the front of the machine

and has the locking knob (Pic.1)14.alreadyfitted.locatethe

elevating handle onto the end of the screw and secure by

tightening the securing screw in the handle (Pic. 4).

MOUNTING THE TILTING HANDLE (PIC. 5)

The tilting screw is located at the side of the machine (Pic. 1)13.

Locate the tilting handle onto the end of the screw and secure

by tightening the securing screw in the handle (Pic. 5).

The blade has been set at the factory to be at an angle of

90° to the table.To check the angle elevate the bladeto its

highest position and using an engineers square or a set square

positioned against the table and the blade, check that the angle

isat90°(Pic. 6).Ifadjustmentisrequiredcarefullyturnthetable

sawover andremove thebottom coverplate.Identifythetilt

angle operating screw (Pic. 7).Theoperatingscrew hastwo

setsof adjustmentandlocking nutsfitted.Thesetof nutsat

themotorendofthescrew,areforsettingthebladeat90°to

thetable0°ontheanglescale.Thesetattheotherendofthe

screw,areforsettingthebladeat45°tothetable45°onthe

anglescale.

SETTING THE BLADE AT 90° TO THE TABLE (PICS.

7 TO 9).

Loosen the lock nut (Pic. 8.1) using two wrenches, one for the

lock nut and one for the adjustment nut (Pic. 8.2) on the motor

end of the operating screw (Pic. 7) and turn the adjustment

nut until the blade is at the 90° to the table. Then turn the

lock nut (while holding the adjustment nut in position) to fix

the adjustmentnut in place. Check the position of the angle

indicatorpointer against the angle scale and adjust to 0° by

looseningthecrossheadscrewandsettingthepointeron0°on

the angle scale (Pic. 9).

SETTING THE BLADE AT 45° TO THE TABLE (PICS.

To check the angle, elevate the blade to its highest position and

usingthetilthandletiltthebladeasfaras itwillgo.Usinga

suitable set square, check the angle of the blade to the table

is at 45°(Pic. 10).If adjustmentis required,locatethe set of

adjustment and locking nuts on the tilt angle operating screw

furthest away from the motor (Pic. 7).Loosenthelocknut(Pic.

11.1) using two wrenches, one for the lock nut and one for the

adjustment nut (Pic. 11.2) and turn the adjustment nut until the

bladeisat45°tothetable.Thenturnthelocknut(whileholding

theadjustmentnutinposition)tofixtheadjustmentnutinplace.

Check the position of the angle indicator pointer against the

anglescaleitshouldnowalignwiththe45°mark.

CHECKING THE BLADE ALIGNMENT (PICS. 12 TO

15)

To check that the blade is set parallel to the two mitre gauge

guidegroovesmachinedinthetable(oneoneithersideofthe

blade).Elevatethebladetoitshighestpointandmarkan“X”on

oneoftheteethwhichisset(Bent)totheleftandtothefront

of the blade slot in the table insert (Pic. 12).Positionthehead

of the combination square in the groove and adjust the blade

of the square so that it just contacts the tip of the marked tooth

(Pic. 13).Slidethecombinationsquaretowardstherearofthe

table and rotate the blade so that the marked tooth is to the rear

oftheslotinthetableinsert.Checkthatthemarkedtoothagain

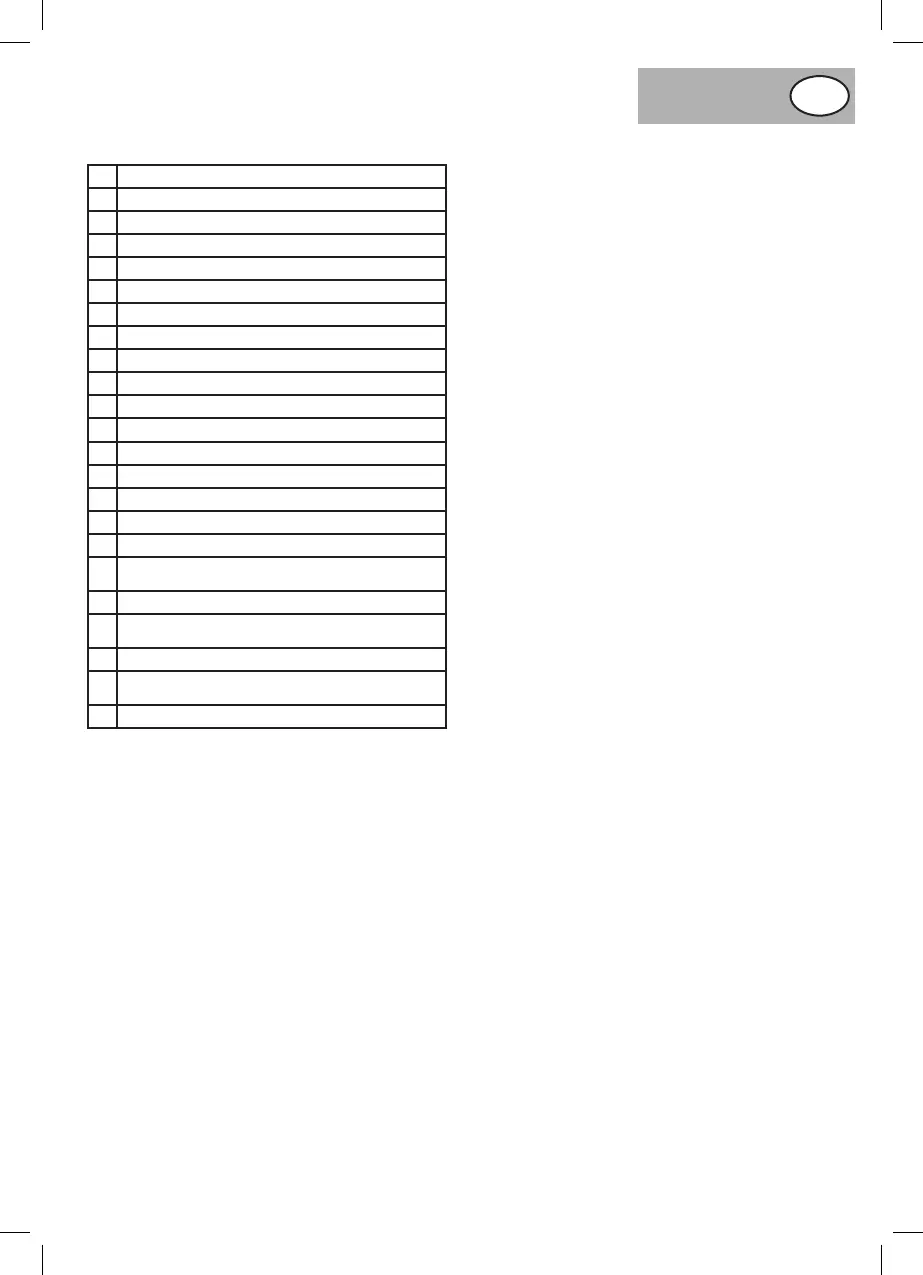

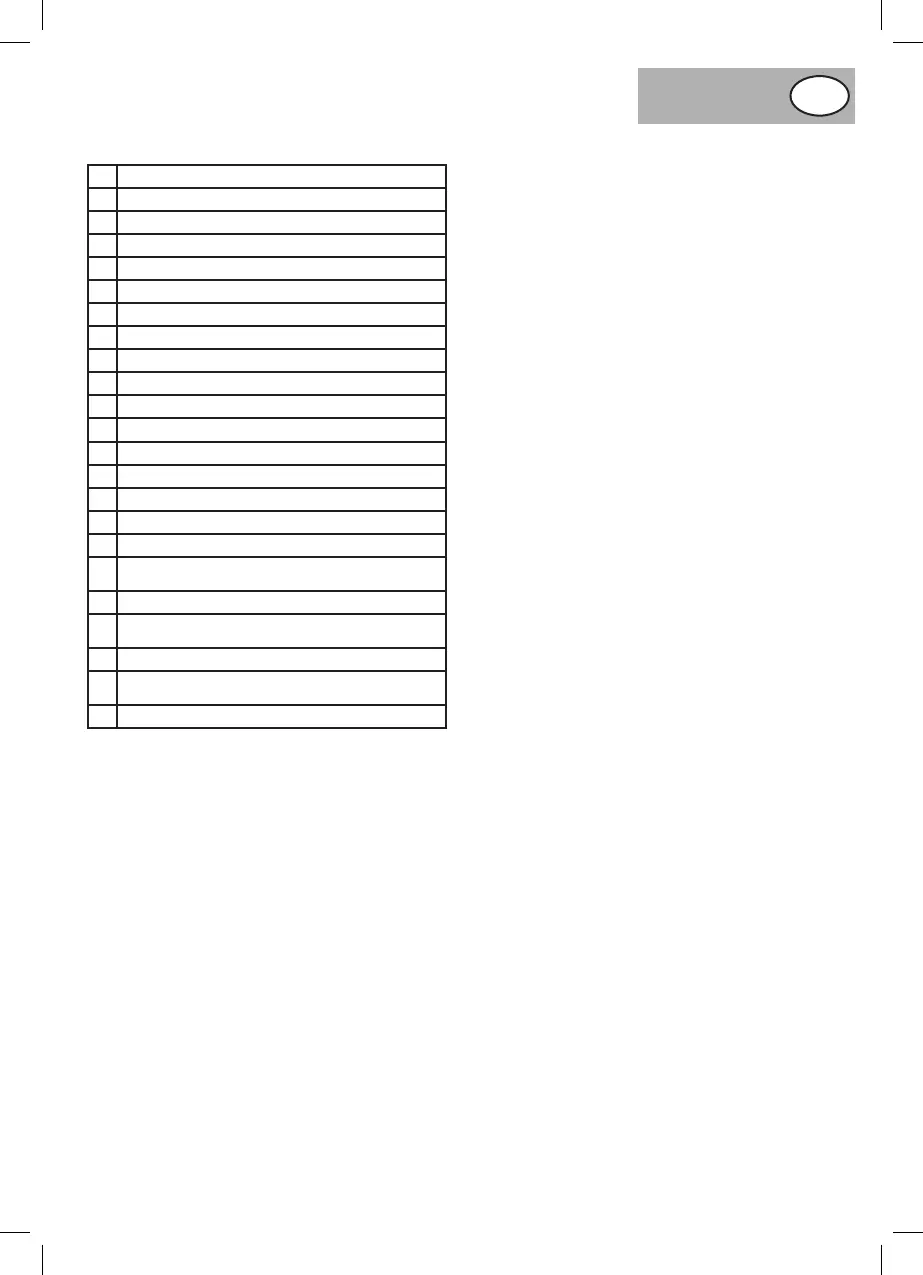

1

Table saw

2

Mitre gauge

3

Ripfence

4

Ripfencemountingblock

5

Ripfencesecuringknobsx2

6

Ripfenceadjustingknob

7

Rivingknife

8

Blade guard

9

Legsx4

10

Uppersupportstrutx4

11

Lowersupportstrutx4

12

Table elevation handle

13

Blade tilting handle

14

Locking knob

15

Table

16

Table insert

17

Tableextension(Left)

18

Table extension support struts

(Left)x2

19

Tableextension(Right)

20

Table extension support struts

(Right)x2

21

Tableextension(Rear)

22

Table extension support struts

(Rear)x2

23

No Volts ON/OFF switch

Loading...

Loading...