GB

16

3 COMPONENTS AND CONTROLS (PIC. 1)

1 Battery

2 Battery release catch

3 On/Off trigger switch

4 Forward/reverse

5 Torque adjuster

6 Hand grip

7 Keyless chuck

8 Hammer action selector collar

9 Charger

10 2 Speed gearbox

11 LED light

VARIABLE SPEED CONTROL (PIC. 2)

Simply apply light pressure to the trigger to start the drill on

a slow speed. Increasing the pressure will allow a variable

speed increase. Always remove the battery before carrying

out any adjustments or maintenance.

KEYLESS CHUCK OPERATION

The keyless chuck fitted to this drill/driver allows for the

easy installation and removal of bits and drills (Pic. 3).

The chuck has two rotating grips (A and B). Select the drill/

driver bit required and insert it into the chuck jaws, turn grip

A in a clockwise direction until jaws grip the drill/driver bit.

With your free hand hold grip B firmly and rotate grip A in

a clockwise direction until it tightens onto the drill/driver bit.

Do not use unnecessary force to tighten.

Re-fitthebattery,yourdrill/driverisnowreadyforuse.

TORQUE ADJUSTMENTS

This feature allows setting of the torque or tightening power

of your drill/driver and depending on the application, various

levels of driving power are required. When driving larger

screw diameters a higher torque power is required to drive

the screw until it’s properly seated.

When the selected torque is reached the chuck will stop

rotating (Pic. 4).

NOTE

-Alwaysstartonthelowestsetting.

The symbol gives the highest torque setting and is

used when drilling and for driving larger screws.

HAMMER ACTION

This Drill has the additional feature of hammer action.

Rotatethetorqueringinananti-clockwisedirectionuntilthe

drill symbol aligns with the arrow on the chuck body (Pic. 5)

Located on the hammer drill/drill ring is the hammer symbol.

Rotate the ring until the hammer symbol is aligned with the

arrow. When using the drill in hammer mode always use

masonry drill bits recommended by your supplier.

FORWARD & REVERSE SWITCH (PIC. 6)

This feature is selected via a slide switch located above the

trigger. To select direction of the drill rotation simply push

the button fully in on the left side for reverse rotation. To

change to forward rotation, push the button fully in on the

right side of the handle.

2 SPEED GEARBOX

NCHD18 / NCHD24

This drill comes with a 2 speed gearbox to give high and low

speed ranges. To change between the two speed ranges

slide the selector switch, located on top of the drill.

WARNING!

The machine is designed as a drill and driver. Do not attach

any other accessories other than those recommended.

NOTE

-Asasafetyprecautionfromaccidentalengagement

while being carried pushing the forward/reverse button

into the middle or neutral position will render the drill

inoperative.

HINTS FOR SCREW DRIVING

1) Use candle or bees wax on the screw threads to speed

application.

2) Whenever possible drill small diameter pilot holes for

faster screwing, eliminating the possibility of splitting

the wood.

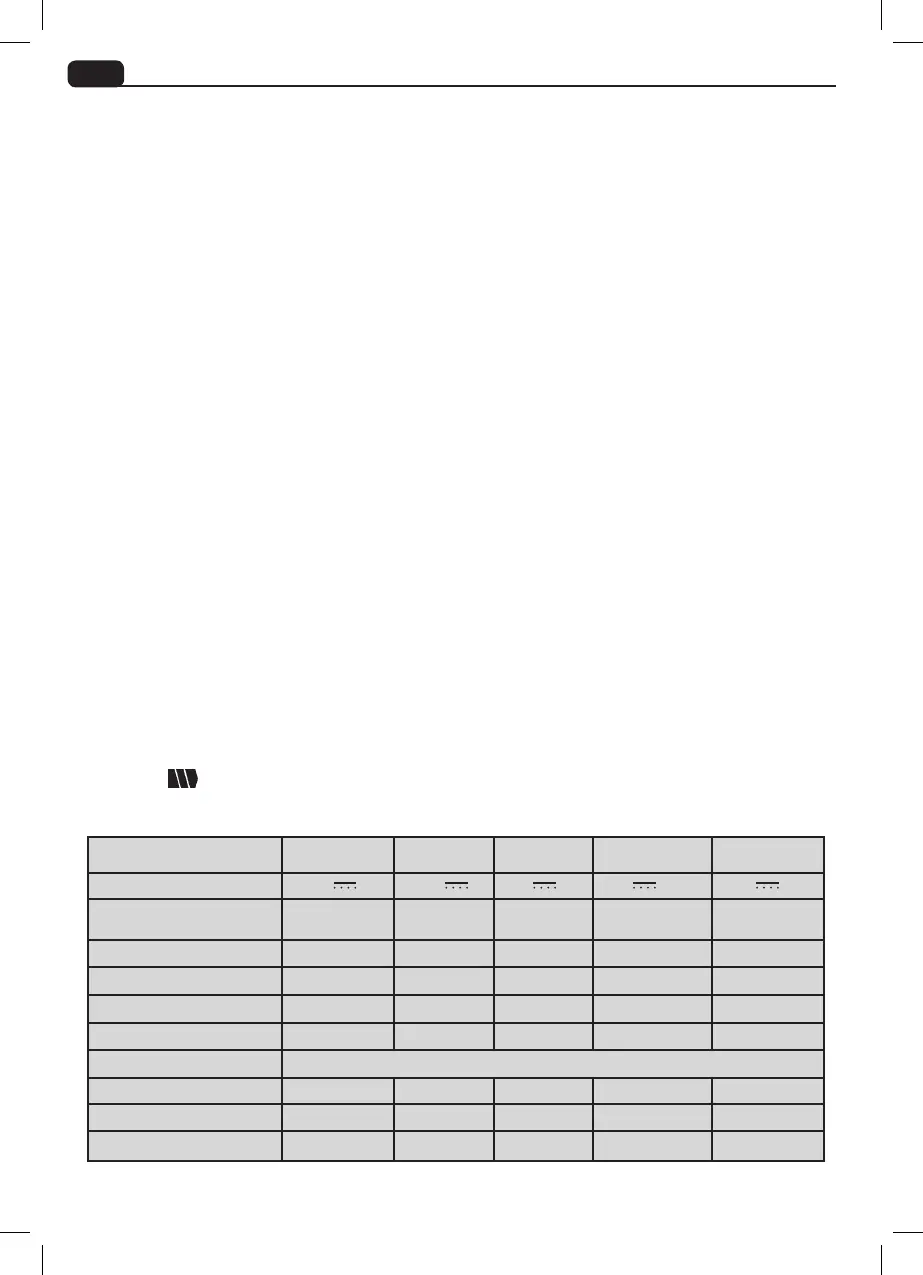

TECHNICAL SPECIFICATION

NCDL144

NCDL144-M

NCD18 NCHD18 NCHD24

Voltage

14,4 V

14,4 V 18 V 18 V 24 V

Variable speed

0-400min

-1

0-1150min

-1

0-550min

-1

0-550min

-1

0-400min

-1

0-1150min

-1

0-400min

-1

0-1150min

-1

Charge time 1 h 1 h 3-5h 1 h 1 h

Sound pressure level LpA 86 dB(A) 83 dB(A) 86 dB(A) 80 dB(A) 80 dB(A)

Sound power level LwA 91 dB(A) 94 dB(A) 97 dB(A) 91 dB(A) 91 dB(A)

Vibration level a = 2,12 m/s

2

a = 1,17 m/s

2

a = 2,12 m/s

2

a = 2,59 m/s

2

a = 2,59 m/s

2

Drill capacity:

Wood 20 mm 20 mm 20 mm 20 mm 25 mm

Metal 8 mm 8 mm 6 mm 6 mm 8 mm

Masonry 0 mm N/A 0 mm 10 mm 10 mm

Loading...

Loading...