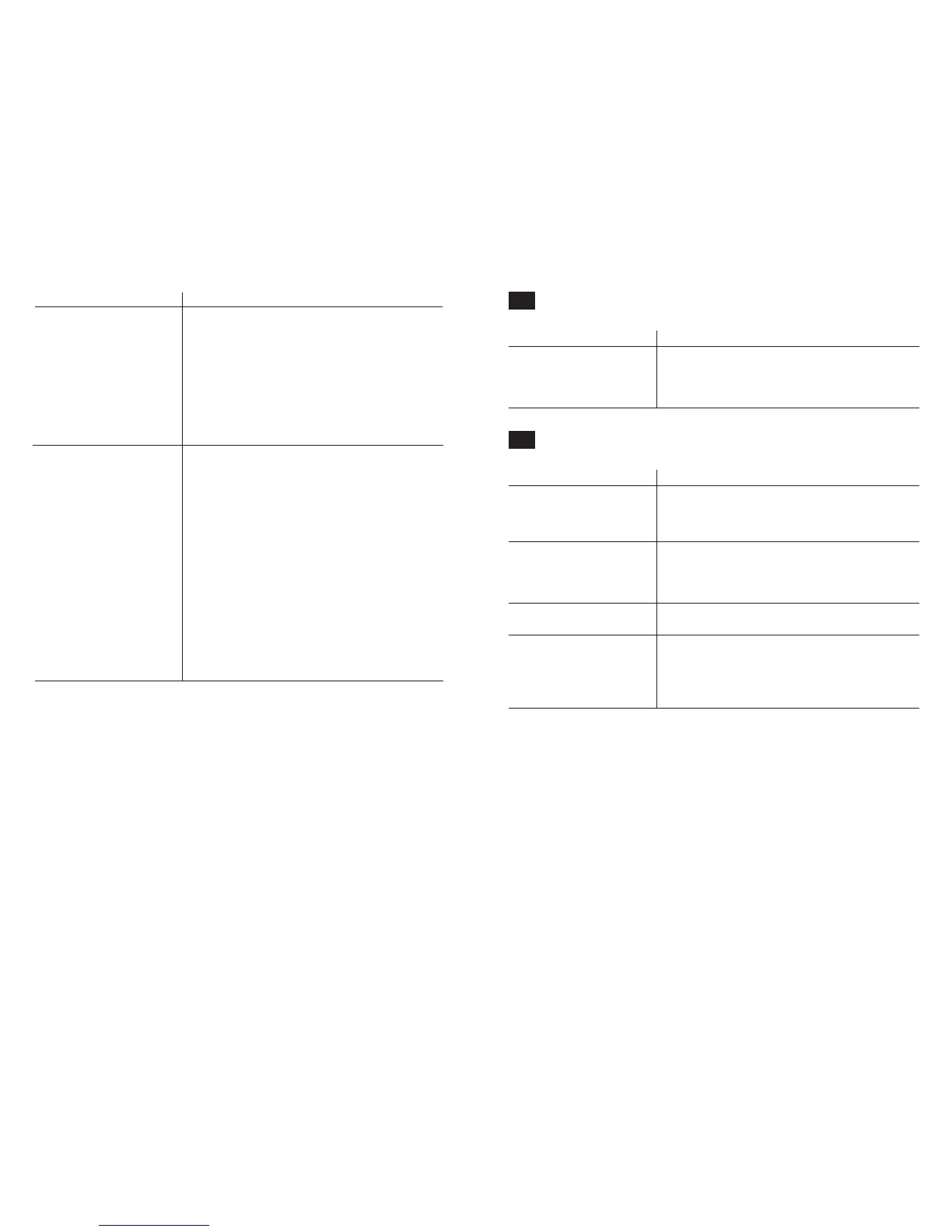

12 13

Problem Solution

Unit will not heat up at all 1) Verify that controller is asking for heat by looking

for heating indicator light – if pilot light is not

on continuously at initial start up, there is a

problem with the controller

2) Check amperage – amperage should be virtually

at maximum rated (data plate) amperage

3) Is the Thermostat set high enough? – for

diagnostics, should be fully clockwise with the

pilot light never on

4) Has the fuse/circuit breaker blown?

Chamber temperature 1) Is ambient room temperature radically changing

unstable; will not maintain – either door opening or room airflow from

set point heaters or air conditioning ? – stabilize

ambient conditions.

2) It may happen if exhaust stack is 100% open –

close exhaust stack.

3) Calibration sensitivity – call Customer Service

4) Thermostat set too low – be sure that it is more

than five degrees over desired set point; check

if pilot is on continuously; turn controller knob

completely clockwise to see if problem solved

then follow instructions in section 6.2 for

correct setting.

5) Assure that set point is at least 5 degrees over

ambient room temperature.

6) See if ambient is fluctuating

7) Verify that reference thermometer is certified.

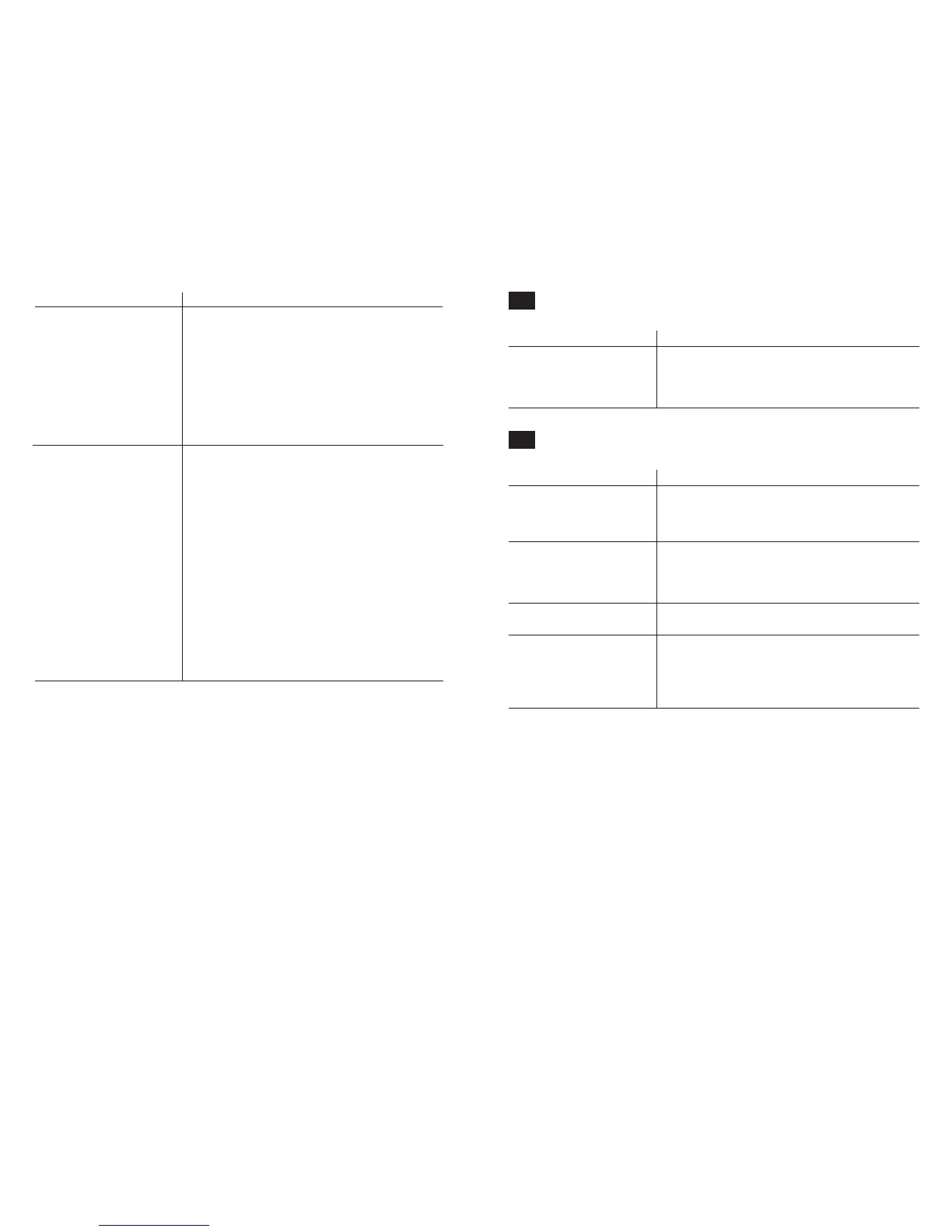

Mechanical

8.2

Problem Solution

Door not sealing 1) Confirm that the door gasket is clean of debris

and aligned properly.

2) Confirm that unit has not been damaged and

that the body is square.

Other

8.3

Problem Solution

Unit or wall fuse/ 1) Check wall power source.

circuit breaker is blown 2) Compare current draw and compare to specs

on data plate.

3) See what other loads are on the wall circuit.

Unit will not turn on 1) Check wall power source.

2) Check fuse circuit breaker on unit or in wall.

3) Check all wiring connections,

esp. around the on/off switch.

Unit is smoking – Put unit under vent and run at full power for

out of box one hour

Contamination 1) See Cleaning procedure, section 3.5

in chamber 2) Develop and follow a standard operating

procedure for specific application; include

definition of cleaning technique and

maintenance schedule

Loading...

Loading...