X9 Series metering pumps Operating manual

Page 20 Copyright © - OBL Metering pumps - All rights reserved File: UT-4336 – Rev.0

GB

6.3.2

Pulsation dampener

The pulsation dampener is particularly important to improve the dosing process and the pump operation.

There are various benefits obtained with its installation:

- protects the pump from high pressure peaks (fluid hammer) increasing lifespan of pump

- flow rate becomes continuous with a linear flow, increasing the reliability of the dosing process

- significant reduction of vibrations transmitted along the discharge pipeline

- help in reducing noise emitted by the pump

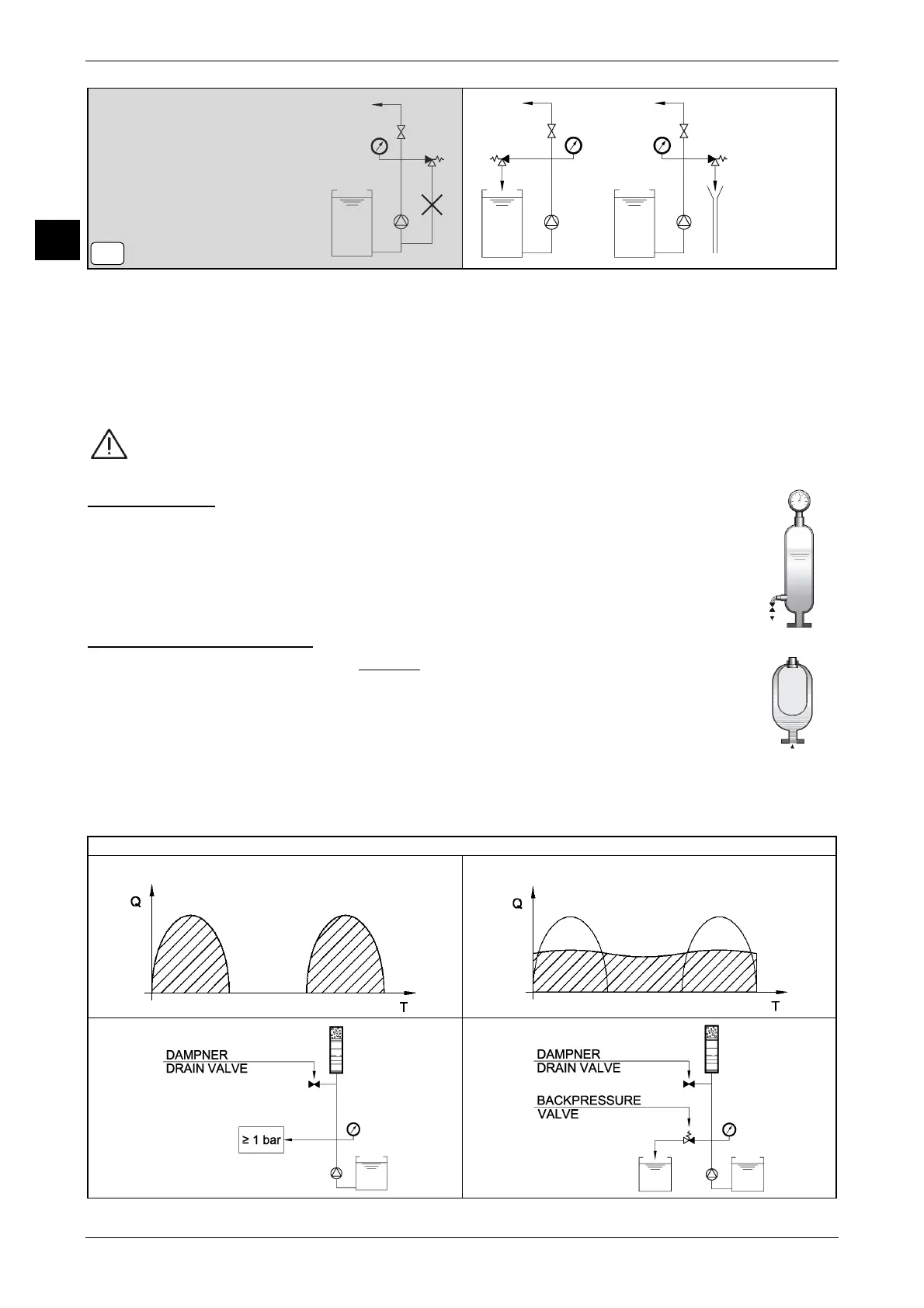

NOTE: If the process require a continuous type flow rate, is essential to install a pulsation dampener.

There are two types of pulsation dampeners on the market:

BOTTLE DAMPENER:

Fluids enters in the dampener and directly compresses the air inside it (without any means of separation).

Dampener volume is approximately 35 times the pump displacement.

Advantages: Less expensive than bladder type dampener. No need for precharge pressure as it self-adjusts.

Disadvantages:

Bulkier than the bladder type dampener. Must be installed “vertically” only. Requires periodic

maintenance. Must be regenerated periodically by discharging fluid and restoring the air inside.

BLADDER DAMPENER (precharged):

Fluids enters in the dampener and compresses a

separation bladder or diaphragm (distension chamber).

Dampener volume is approximately 8 times the pump displacement.

Advantages: More compact than

bottle type dampener. Can be installed vertically or horizontally. No need periodic

maintenance and not requires to be regenerated as the precharge gas always remains enclosed in the bladder.

Disadvantages: More expensive than the bottle type dampener. It

is necessary to know the pump actual operating

pressure beforehand to determine the correct bladder precharge pressure. The pump working pressure must always be

higher than the precharge pressure.

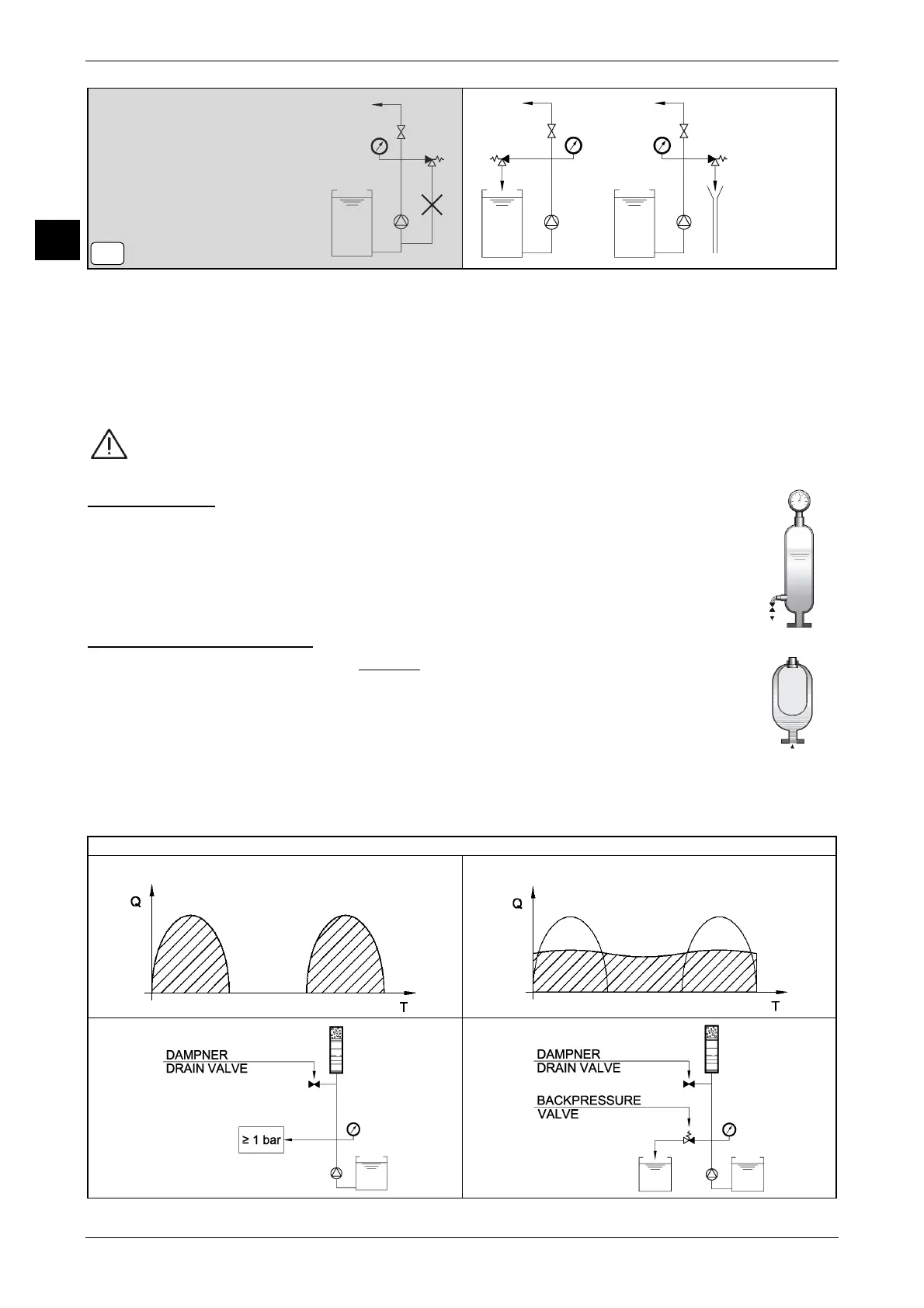

Figure 10 shows some pulsation dampener examples of installation.

Figure 10 PULSATION DAMPENER INSTALLATION

9-B

Recirculation on suction pipeline may

compromise pumps suction lift ability

PULSING flow rate (without pulsation dampener)

Loading...

Loading...