Operating manual X9 Series metering pumps

File: UT-4336 – Rev.0 Copyright © - OBL Metering pumps - All rights reserved Page 33

GB

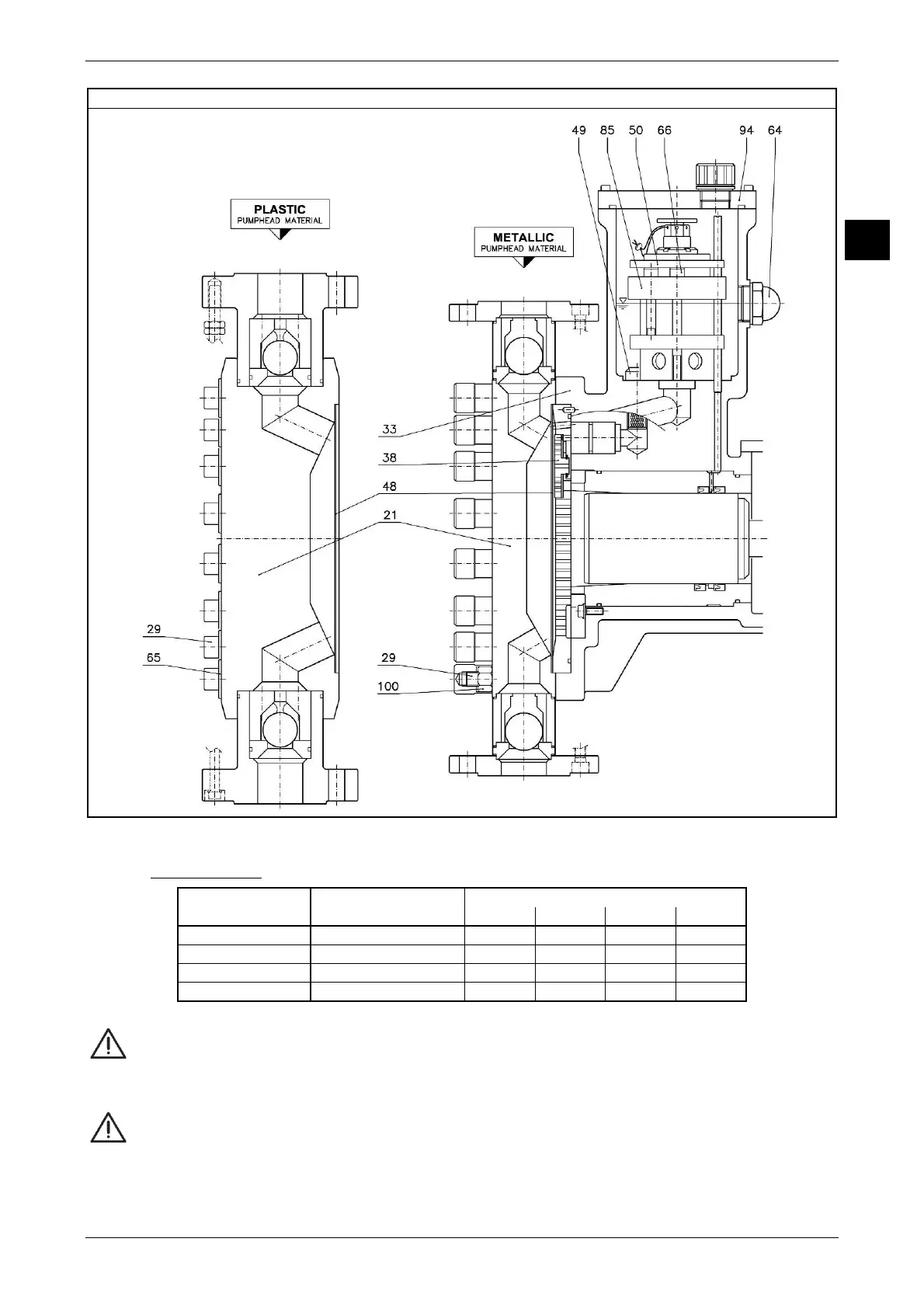

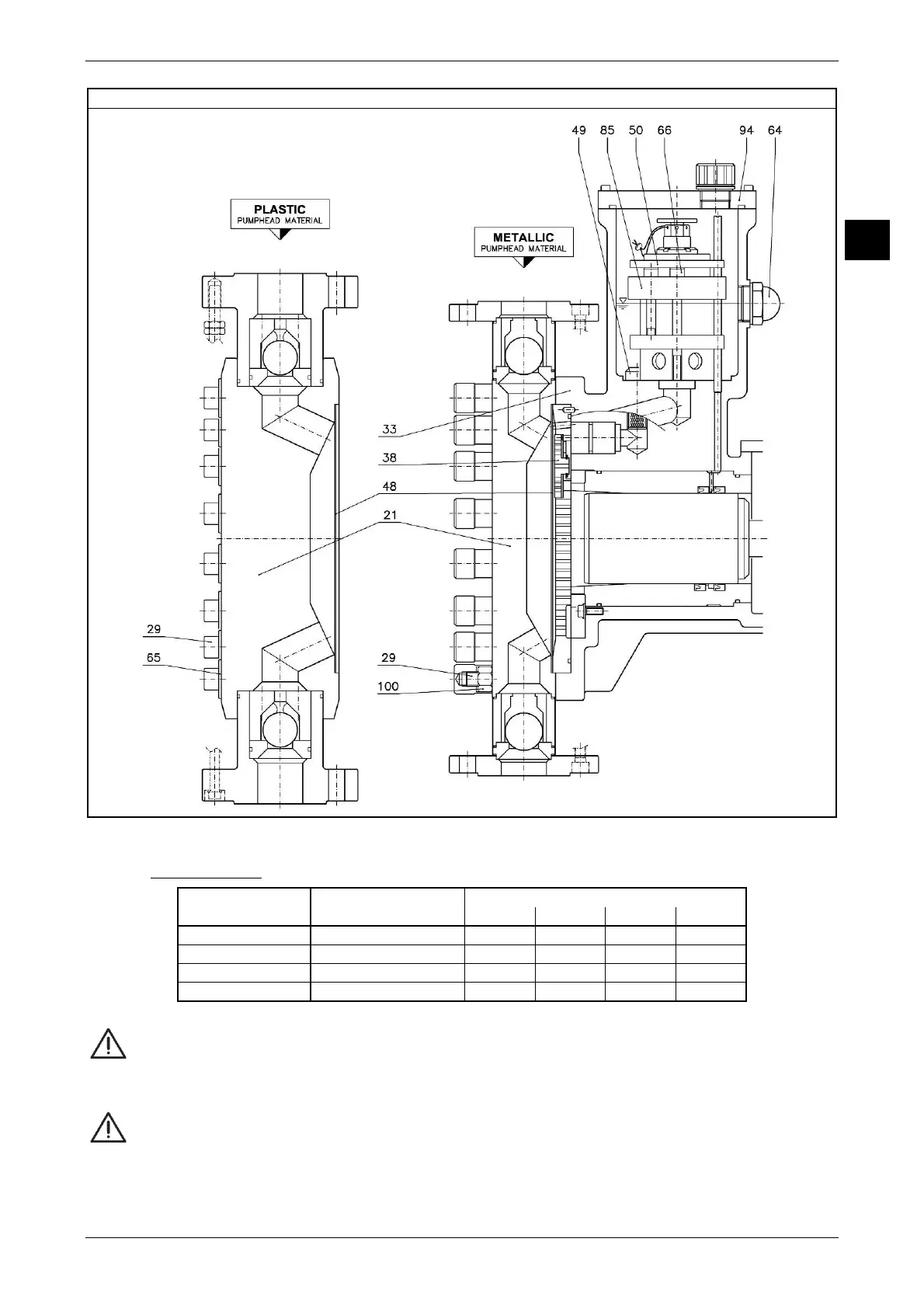

Figure 17 LN, LP PUMPS: PUMPHEAD

8.2.6

Pumphead tightening torque values

The table below shows the tightening torque for correct pinching the diaphragm and locking the pumphead.

The values are purely indicative and refer to temperatures indicated in "Ambient and design temperature".

Nut (pos.100) METALLIC PLASTIC pumphead material

Screw (pos.29) * pumphead material PVC (P) PVDF (S)

PTFE (T) PP (PP)

M 8 25 Nm 12 Nm 12 Nm 10 Nm 12 Nm

M 10 45 Nm 25 Nm 30 Nm 20 Nm 25 Nm

M 12 75 Nm 60 Nm 60 Nm 50 Nm 60 Nm

M 16 180 Nm 100 Nm 100 Nm 90 Nm 100 Nm

* (pos.29): For metallic pumpheads material is a 8.8 stud bolt, for plastic pumpheads material is a screw type TCCE in AISI-304.

NOTE: For pumps with plastic material pumphead (where applicable) always use the washer (pos.65) to

ensure appropriate load distribution, in order to avoid deformations or damage to the pumphead.

8.2.7

Pumps with plastic material pumphead: Recommendations

NOTE: The customer (user and/or installer) must implement these recommendations.

Pumps with plastic material pumphead, compared to the metallic material, require a higher level of attention because of the mechanical

characteristics of the material and the nature and/or danger of the chemical being pumped.

Define the most appropriate pumphead tightening torque value, considering also the following factors:

Loading...

Loading...