13

Publication No: US-ODY-TM-001 - April 2011

www.odysseybattery.com

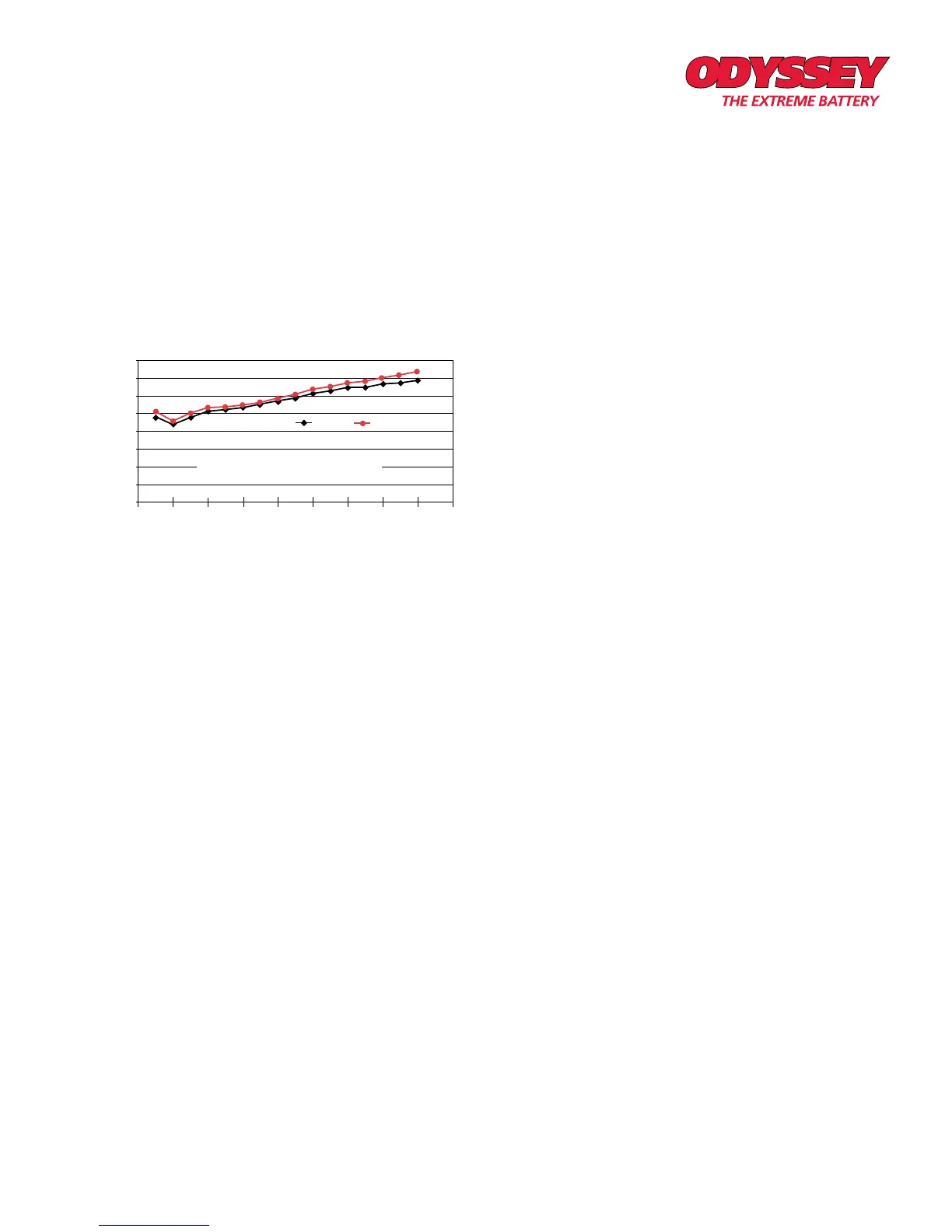

(2) High temperature discharged storage test

Two PC1200 samples were discharged in this test at the

1-hour rate to 9V per module, and then placed in storage at

50°C (122°F) in a discharged condition for 4 weeks.

At the end of 4 weeks, the two batteries were recharged

using a constant voltage (CV) charge at 14.7V per battery.

As Figure 4 below shows, both samples recovered from this

extreme case of abusive storage.

Figure 4: Recovery from high temperature discharged

storage

Deep Discharge Recovery Procedure

It is not unusual for batteries, particularly in automotive or

other engine starting applications to get over discharged

due to factors such as parasitic loads that drain batteries

in vehicles that are not used for extended periods of time.

Leaving a dome light on over a weekend can also have the

same effect on a battery.

This section will describe two separate procedures to

recover a deeply discharged ODYSSEY

®

battery. The first

procedure is for the average consumer who only has access

to a typical automotive charger for home use and sold in

auto parts stores.

Procedure #2 should be attempted by someone who has

access to more sophisticated charging equipment such as

regulated DC power supplies and has the capability to safely

discharge a battery using a controllable load bank.

Although over discharging a battery is not recommended,

ODYSSEY batteries have a much higher level of tolerance

for this kind of abuse than traditional starting, lighting and

ignition (SLI) batteries. Should an ODYSSEY battery be over

discharged and conventional charging techniques fail to

recover it, the following protocols may be used to recover

the battery. It is important to note that even if the battery

recovers following implementation of either protocol, it may

suffer some level of permanent damage.

Procedure #1

Since most typical automotive chargers for home use have

a built-in safety feature that prevents them from turning on

if the battery voltage is too low, this procedure may require

the user to “jump” the dead battery to a healthy battery by

connecting the positive of the dead battery to the positive

of the healthy battery; similarly the negative of the dead

battery must be connected to the negative of the healthy

battery.

Once the two batteries are connected as described above

the battery charger can be hooked up according to the

charger manufacturer’s procedure to the terminals of the

dead battery. The dead battery should now start accepting

a charge.

Continue charging for a while, then unplug the charger and

disconnect the healthy battery from the over discharged

battery. Then reconnect the charger to the discharged

battery and finish the charge.

Procedure #2

1. Bring the battery to room temperature—25°C (77°F)—if it

is not already there.

2. Measure the open circuit voltage (OCV). Continue to step

3 if it measures at least 6.00V.

3. Charge the battery for 24 hours using a constant current

charge that is 5% of the 20-hour capacity of the battery

(5A for a 100Ah battery). The charger should be able to

provide a driving voltage as high as 18.00V. Monitor the

battery temperature; discontinue charging if the battery

temperature rises by more than 20°C.

4. Allow the battery to stand for 18 hours after completion

of step 3.

5. Perform a capacity test on the battery and record the

amp-hours delivered. The longer the discharge the more

reliable the result. This is Cycle 1.

6. Repeat steps 3 through 5. The capacity noted in step 5

is the Cycle 2 capacity. Proceed to step 7 only if Cycle

2 capacity is greater than Cycle 1 capacity; otherwise

replace the battery.

7. Repeat steps 3 through 5 to get Cycle 3 capacity and

proceed to step 8 only if Cycle 3 capacity is equal to or

more than the capacity in Cycle 2. Replace the battery

if Cycle 3 capacity is less than Cycle 2 capacity. If the

capacity is greater than or equal to 80% of the rated

capacity of the battery it may be returned to service.

8. Recharge the battery and put back in service if Cycle 3

capacity is equal to or exceeds Cycle 2 capacity.

Cycle number

10

86 420

12

14 16 18

36

34

32

30

28

26

24

22

20

Sample 1

Sample 2

Capacity at the 1-hr rate

Constant voltage recharge at 14.7V per module

Current limit for cycles 1 & 2 : 0.125C10

Current limit for cycles 3 - 16 : 1C10

Loading...

Loading...