18

Publication No: US-ODY-TM-001 - April 2011

www.odysseybattery.com

4. Long Test: Discharge the battery using a resistor or other

suitable load until the voltage drops to 10.00V and record the

time taken to reach this voltage. Let the battery rest for an

hour and repeat Steps 1 through 4. If the time taken by the

battery to drop to 10.00V is longer in the second discharge

than in the first discharge, the battery may be returned to

service after a full recharge; if not the battery should be

rejected as having reached end of life.

5. ½CCA Test: Battery OCV must be at least 12.60V to proceed

with this test. Connect the load tester cables and the voltage

leads of a separate digital voltmeter (if the tester does not

have a built-in digital voltmeter) to the battery terminals.

6. Adjust the tester load current to lad the battery to half its

rated CCA and apply the load for 15 seconds. Table 7 shows

the ½CCA values for all ODYSSEY

®

battery models. Use

Table 8 to adjust the battery end of test voltage temperature.

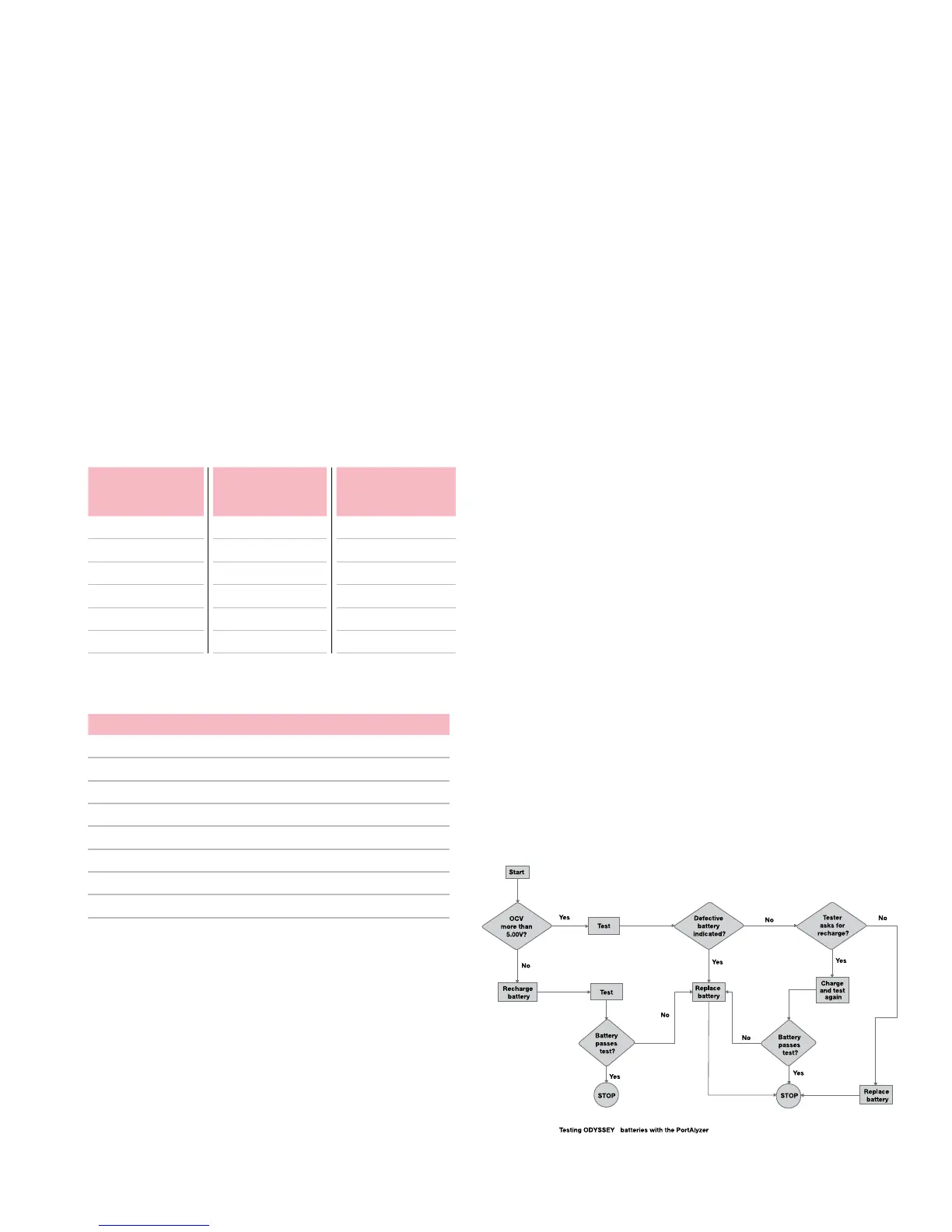

Table 7

ODYSSEY

®

Battery

Model

½CCA

Test

Value (A)

ODYSSEY

®

Battery

Model

½CCA

Test

Value (A)

ODYSSEY

®

Battery

Model

½CCA

Test

Value (A)

PC310 155 PC1200 275 PC1700 438

PC535 100 PC1220 340 PC1750 465

PC545 93 PC1230 365 PC1800 650

PC625 133 PC1350 480 PC2150 575

PC680 110 PC1400 410 PC2250 613

PC925 190 PC1500 440

Table 8

Temperature End of Test Voltage

70°F 9.60V

60°F 9.50V

50°F 9.40V

40°F 9.30V

30°F 9.10V

20°F 8.90V

10°F 8.70V

0°F 8.50V

7. At the end of 15 seconds note the battery voltage on the

voltmeter and discontinue the test. If the temperature is

70°F or warmer the battery voltage should be at or above

9.60V. If so the battery can be returned to service; if below

9.60V the battery should be rejected.

ODYSSEY

®

BATTERIES IN NO-IDLE

APPLICATIONS

Since these batteries are dual purpose in nature they can be

used for both engine starting and deep cycling applications.

This makes them particularly well suited for fleets such as

police vehicles that would like to power their computers

and communications equipment without having to idle their

engines. Auxiliary power units (APU) on trucks provide

another example of a no-idling application. All of these

require energy sources to power loads such as computers

and refrigerators with the engines shut off to reduce their

carbon footprints and lower gas consumption.

As discussed in a previous section, properly charged

ODYSSEY batteries are capable of delivering as many as 400

cycles to an 80% depth of discharge (DOD) at the 5-hour rate

of discharge. A shallower discharge will yield higher cycles,

as noted in the cycle life vs. DOD graph shown earlier.

This is the reason why ODYSSEY batteries are becoming

increasingly popular in APU and police fleet applications

that require batteries to have both high cycling and excellent

engine cranking capabilities in the same package.

ODYSSEY

®

PORTALYZER

TM

TESTER

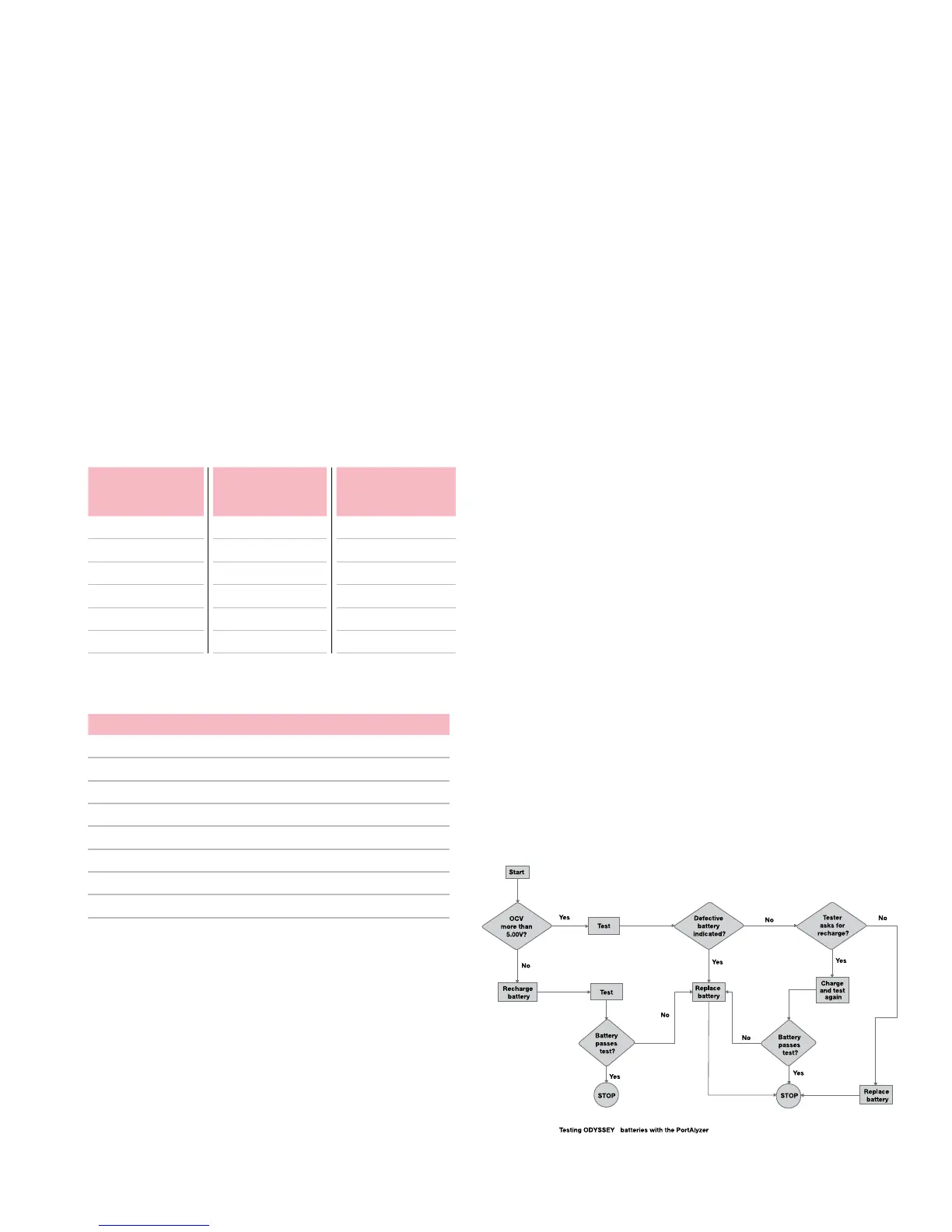

The ODYSSEY battery PortAlyzer™ Tester (PAT) is designed

to quickly assess the condition of ODYSSEY batteries

without applying a heavy load on them. It is portable and

shows test results in a matter of a few seconds.

The tester applies a series of micro loads and determines the

condition of the battery based on how its voltage rebounds

– the weaker the battery the more sluggish the voltage rise

when the load is removed. The test procedure using a PAT is

shown in the flowchart below.

Although the tester displays a cold cranking amp

(CCA) rating for the tested battery, it should be treated

with circumspection as the value is calculated using a

mathematical relationship and not based on a load test.

A true CCA test involves a 30-second load applied to the

battery at 0°F (-18°C), so a result based on a mathematical

formula is inherently not very accurate.

Loading...

Loading...