13

5 Fill Oil

Note!

This procedure requires Öhlins Filling Machine. See separate manual for

Öhlins Filling Machine for proper use.

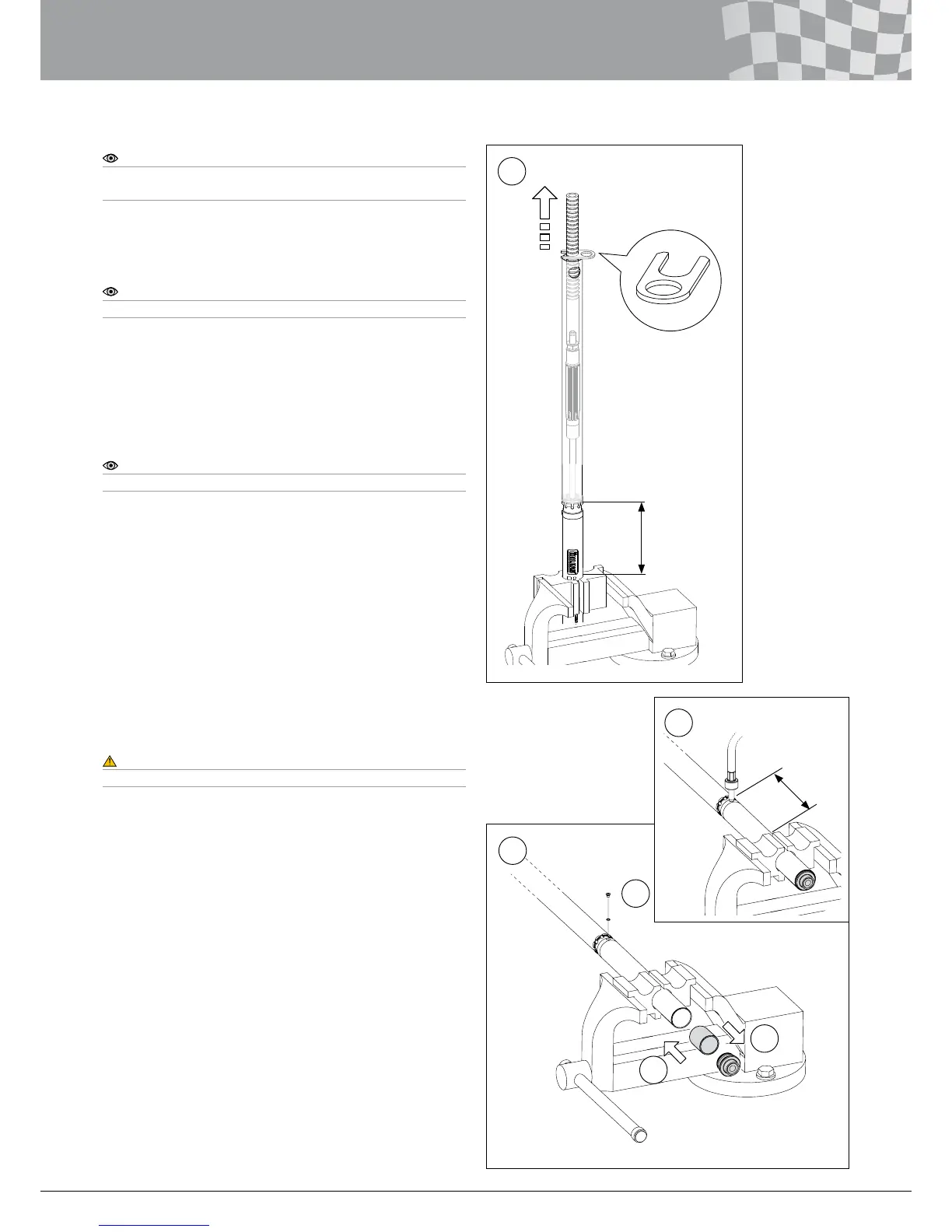

5.1

Use tool 01797-05 and tool 02810-01 to compress the Top out

spring with tool 01765-03. Keep the Top out spring compressed

during remaining steps of the lling procedure.

Note!

Ensure that the Top out spring is fully compressed.

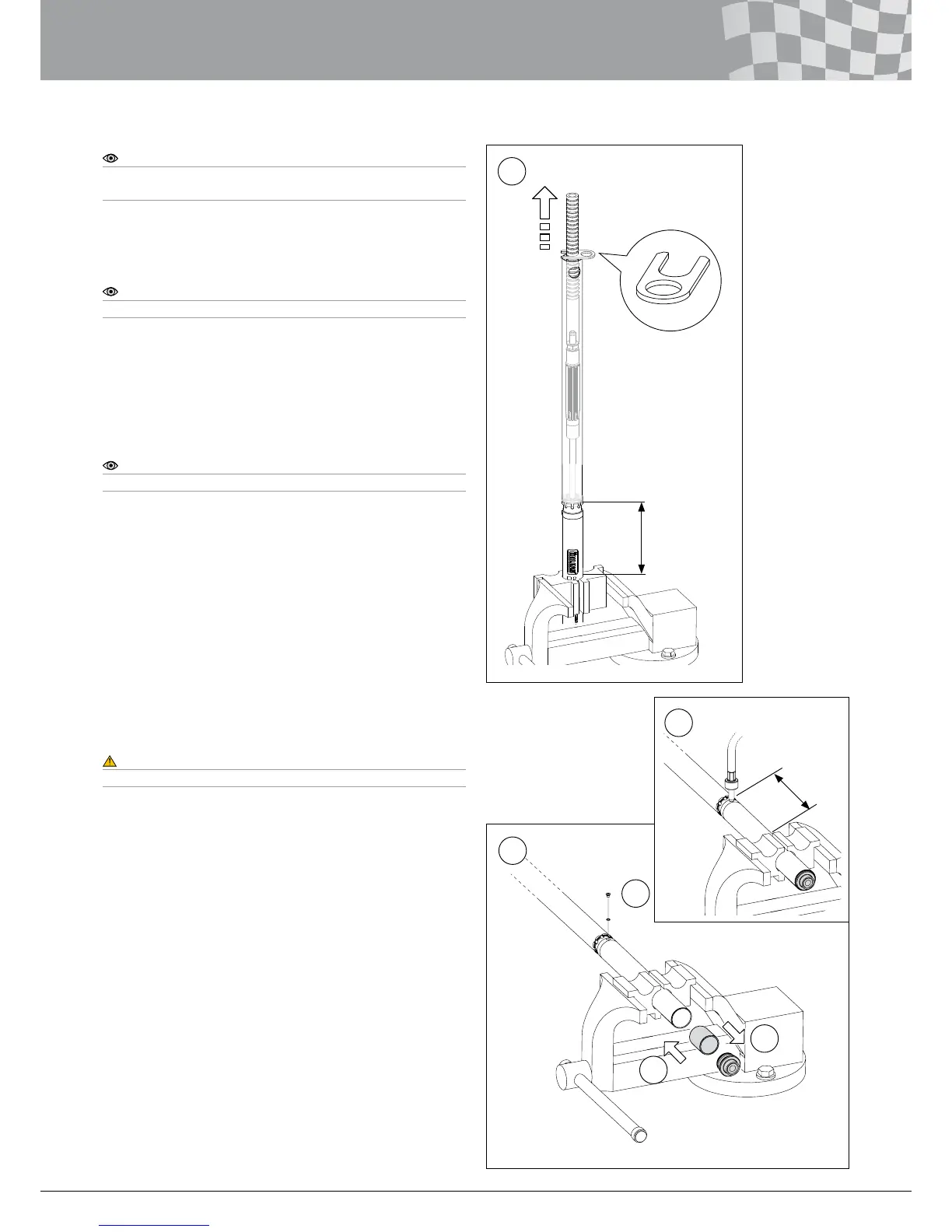

5.2

Turn the Shaft assembly to a horizontal position in the vice.

5.3

Use tool 01460-68 as a spacer in the cylinder tube to achieve

correct position for the Dividing piston. Use Adaptor without

O-ring as a stop by screwing it all the way into the Cylinder tube.

Handtighten only.

Note!

O-ring shall not be installed on the Adaptor.

5.4

Remove the Fill screw. Check the O-ring. Replace if damaged.

5.5

Use tool 01820-24 together with the lling machine and mount it in

the lling hole in the Cylinder tube extension. Fill the system (See

Öhlins Filling Machine Manual).

5.6

Disconnect lling machine and remove tool 01820-24.

5.7

Mount the Fill screw together with the O-ring. Tightening torque 3.5

Nm

5.8

Remove the Adaptor and tool 01460-68.

Warning!

It is important that you remove the Dividing piston positioning tool.

5 FILL OIL

5.1

5.2

5.3

5.4

5.5

5.8

approx 100 mm

approx

100 mm

Loading...

Loading...