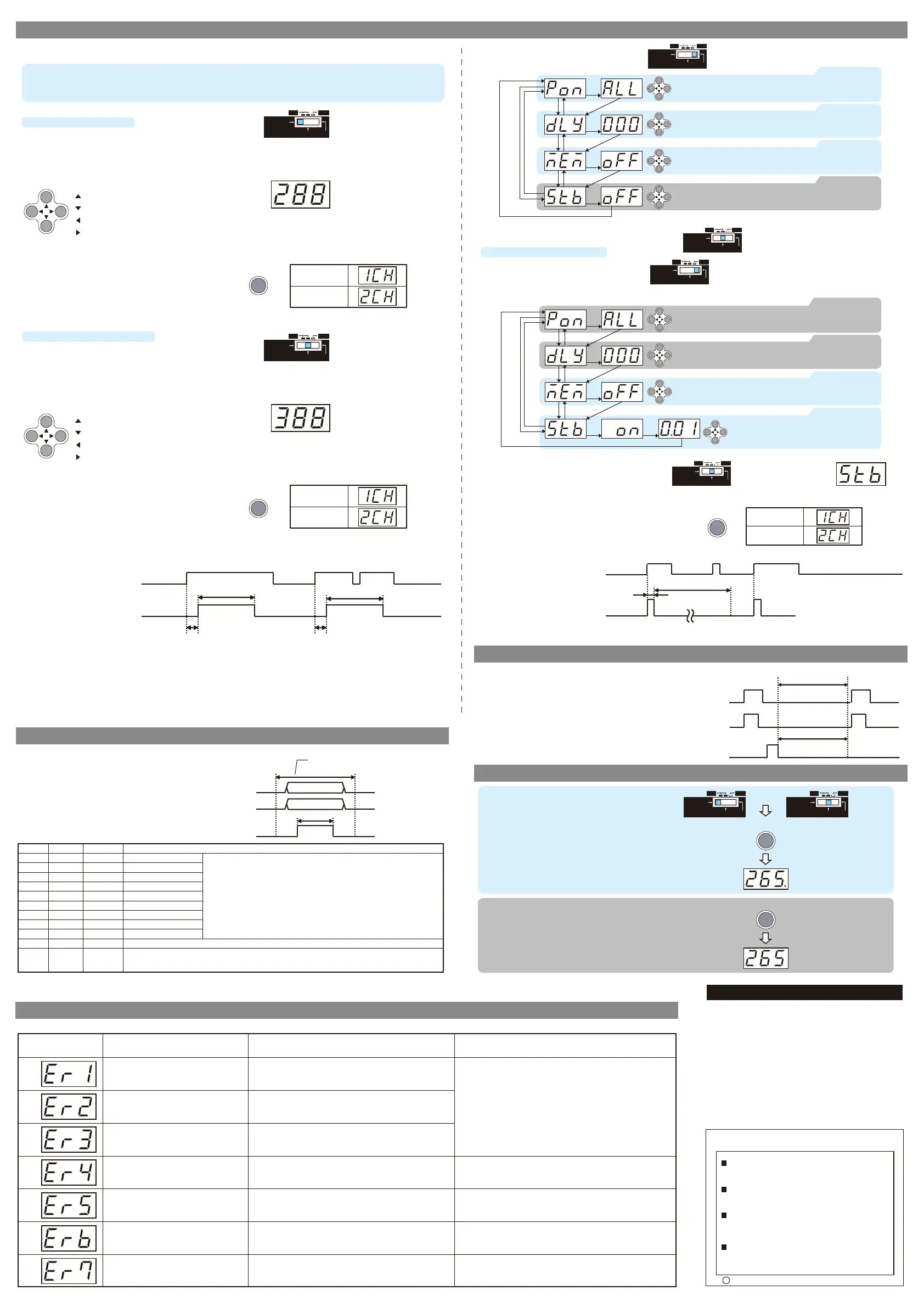

Er1

Er2

Er3

Er4

Er5

Er6

Er7

OvercurrentatCH1

OvercurrentatCH2

OvercurrentatCH1andCH2

Wrighterrorbyparallelinput

NolightconnectedinCH1

Nolightconnected

Overvoltagefrompowersupply

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Stoplightemission

-ErroroutputON(parallelDO1:ERR)

-Shutdownthecontroller(powersupply)andcheckthelightcondition

andwiring.Thenrestartcontroller.

*Ifeverythingiscorrectbuterrorhappens,theproduct

(lightorcontroller)wouldbedefected.

-InputErrorClear(parallelDI10:CLR)

*Aftererrorclear,tryagainwithcorrecttiming

-Shutdownthecontroller(powersupply)andcheckthelightcondition

andwiring.Thenrestartcontroller.

-Shutdownthecontroller(powersupply)andcheckthelightcondition

andwiring.Thenrestartcontroller.

-Shutdownthecontroller(powersupply)andcheckthelightcondition

andwiring.Thenrestartcontroller.

■Mode selection

3 mode for lighting. Use certain one you want.

(1) CONTINUOUS mode (CONT) : continuously lighting

(2) EXTERNAL TRIGGER mode (TRIG) : lighting by trigger input

(3) STROBE mode (STB) : lighting 2 times brighter by trigger input

■ Lighting condition setting for each mode

(1) CONTINUOUS mode(CONT)

- Mode change SW to “CONT”

- Lighting level setting

Set by cross key to change digital value. 400 steps from

1(MIN) -399 to ALL(MAX).

- Lighting level setting

Set by cross key to change digital value. 400 steps from

1(MIN) -399 to ALL(MAX).

- Changing CH

Setting CH changes when CH/ENT key is pushed CH1<>CH2.

After push CH/ENT key, CH number is displayed 1sec.

- Digital value changes by pushing operation key. This value is

synchronized with light intensity in real time. Adjust value

with checking light intensity.

- Digital value changes by pushing operation key. This value is

synchronized with light intensity in real time. Adjust value

with checking light intensity.

7.Setting

11.Error message

10.Key lock function

8.Memory function (MEM)

Attention

- After changing value, when 5 sec have passed with no

operation,the value is saved automatically.

Attention

- After changing value, when 5 sec have passed with no

operation,the value is saved automatically.

Attention

Do not look straigt to lightings when changing mode SW. The lightings flashes when the mode SW is changed CONT ⇒TRIG or SET ⇒TRIG.

Attention

Do not look straigt to lightings when changing mode SW. The lightings flashes when the mode SW is changed CONT ⇒TRIG or SET ⇒TRIG.

Important

Do not input TRIG1/2 during setting by parallel input. Make sure the timing is correct.

Important

With 2CH controller, each CH have to be same mode. If one CH is set to STB mode. The other CH is automatically set to STB mode.

Each signal have to be fixed before and

after “SAVE ON” timing

· Timing chart

1) Change Mode change SW to “SET”

2) Set according to the setting flow

- Emission delay : 0 – 999ms by 1ms (default 0ms) *

- Emission time : 0.1ms – 99.9ms by 0.1ms (default ALL)

ALL : light emitting as long as the trigger is ON

* Emission delay and Emission time can be set in SET mode.

TRIG1/TRIG2

ON

Pluse delay time(Tdelay) Pluse delay time(Tdelay)

Pluse ON time(Tpulse-on)

Pluse ON time(Tpulse-on)

OFF

Light ON

Light OFF

Lighting CH1/CH2

TRIG1/TRIG2

Strobe ON time(ms)

Invalid period of re-trigger input(ms)

ON

OFF

Light ON

Light OFF

Lighting CH1/CH2

・Timing chart

TRIG1/TRIG2

Lighting

CH1/CH2

SAVE

ONLIGHTING OFF

SETTRIG

CONT

(2)EXTERNAL TRIGGER mode (TRIG)

- Mode change SW to “TRIG”

(3)STROBE mode

- Change to STROBE mode by 1) to 3) process

ONLIGHTING OFF

SETTRIG

CONT

ONLIGHTING OFF

SETTRIG

CONT

1) Change Mode change SW to “SET”

2) Set according to the setting flow

ONLIGHTING OFF

SETTRIG

CONT

3) Change Mode change SW to “TRIG”

ONLIGHTING OFF

SETTRIG

CONT

ONLIGHTING OFF

SETTRIG

CONT

ONLIGHTING OFF

SETTRIG

CONT

· Operation key

(UP):Inclease value

(DOWN):Decrease value

(LEFT):Change setting colum to left

(RIGHT):Change setting colum to right

· Operation key

(UP):Inclease value

(DOWN):Decrease value

(LEFT):Change setting colum to left

(RIGHT):Change setting colum to right

CH/ENT

CH/ENT

- Timing chart (TRIG mode)

The light is emitting by external trigger as the chart.

- Strobe time : 0.01 – 5.00ms by 0.01ms

- Invalidation time : Strobe time x 12

The pulse is ignored when the light is emitting.

Keep push 5sec

or

Keep push 5sec

Key lock ON

The dot displayed lower right

- Timing chart (STB mode)

The light is emitting with external trigger as the chart.

■ Key lock function setting

Whole settings are locked by pushing CH/ENT key 5

sec at CONT or TRIG mode

In Key lock condition, only the the Light intensity

value display for each CH can be changed by

CH/ENT key.

■Release Key lock

Push CH/ENT 5 sec

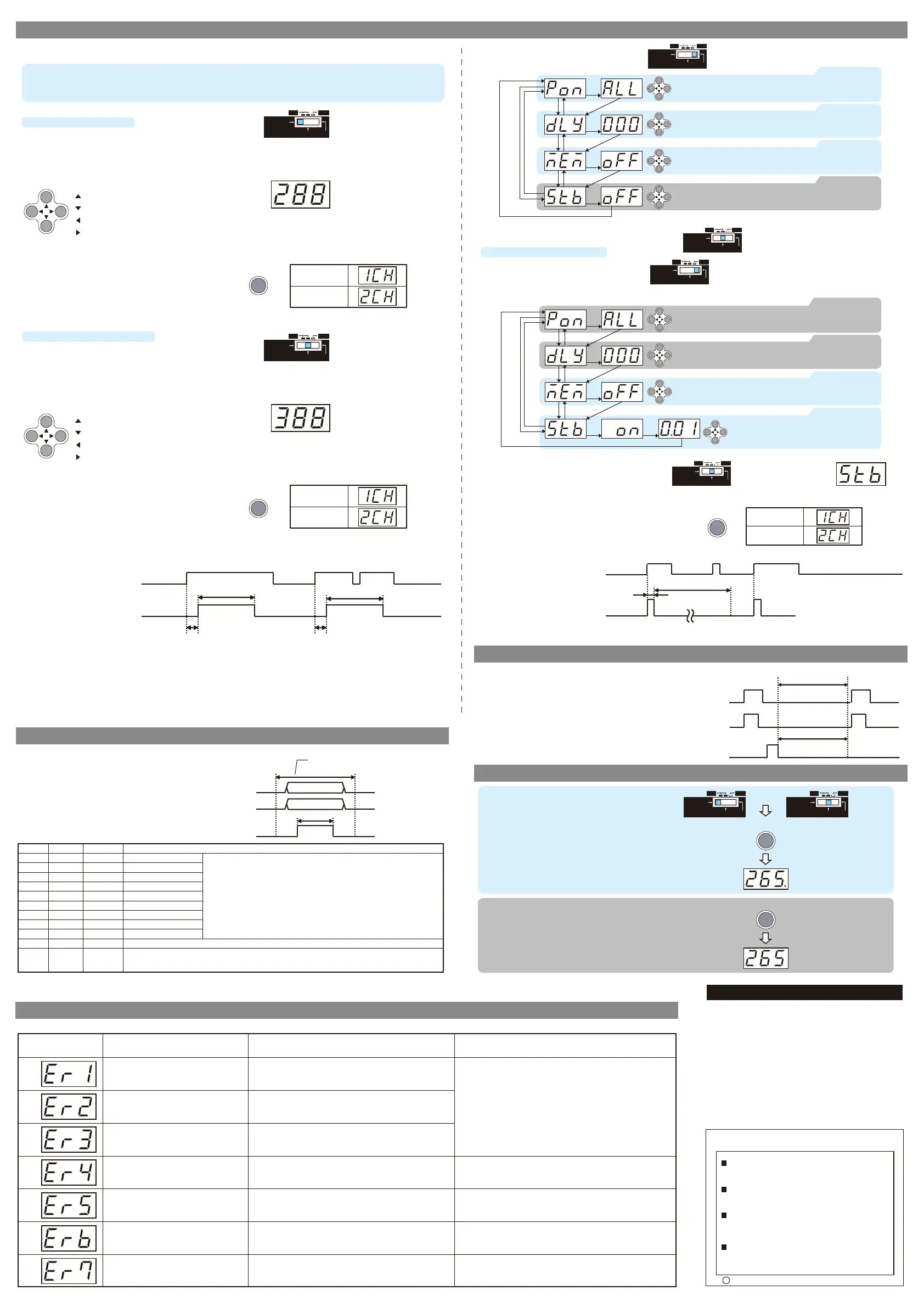

9.Lighting level setting by parallel input

PIN No.

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DI11

DI12

Signal

D1

D2

D3

D4

D5

D6

D7

D8

D9

SEL

SAVE

I/O

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Fanction

Data 1bit(low)

Data 2bit

Data 3bit

Data 4bit

Data 5bit

Data 6bit

Data 7bit

Data 8bit

Data 9bit(High)

CH select(OFF:CH1,ON:CH2)

Memory function “ON”: The data stored in FLASH memory .

Memory function “OFF” : The data stored in RAM memory .

For more information please refer to “7. Setting ”

1) CONT/TRIG mode

Set Luminance value by D9 – D1, 9bit binary data.

Range 1 – 400 (binary 000000001 – 110010000)

2) STB mode

Set Strobe Lighting time by D9 – D1, 9bit binary data.

Range 0.01 – 5.00ms (1 – 500 binary 000000001 – 111110100)

The following setting is possible by parallel input.

1)

CONT mode and TRIG mode : light intensity value change

2) STB mode : Strobe emission time

Process of parallel input

- Input D1 – D9 binary data

↓

- Select CH by SEL input

↓

- The value will be fixed by SAVE input.

- Changing CH

Setting CH changes when CH/ENT key is pushed CH1<>CH2.

After push CH/ENT key, CH number is displayed 1sec.

- Changing CH

Setting CH changes when CH/ENT key is pushed CH1<>CH2.

After push CH/ENT key, CH number is displayed 1sec.

Display changing

2CH → 1CH

Display changing

1CH → 2CH

CH/ENT

CH/ENT

Display changing

2CH → 1CH

Display changing

1CH → 2CH

Display changing

2CH → 1CH

Display changing

1CH → 2CH

3) Change Mode change SW to “TRIG”,“Stb” is displayed

if succeeded.

ONLIGHTING OFF

SETTRIG

CONT

SAVE

SEL

D1-D9

ON

0.5ms or more

OFF

Key lock OFF

The dot disappeared

CH/ENT

Display Reasonoferror

Errormassagelistandwaytorecover

Behavior Waytorecover

(*)stbisdisplayedatthe

TIRGSW.

▲ Key

▲ Key

▼ Key

▲ Key▼ Key

▼ Key

▲ Key

CH/ENT Key

CH/ENT Key

CH/ENT Key

CH/ENT Key:fix value

CH/ENT Key:fix value

CH/ENT Key:fix value

▼ Key

Pluse ON time setting

Pluse Delay time setting

Memory function setting

Change by cross key. Default value “ALL”

range: · 0.1ms-99.9ms(time)

· ALL(Lightings ON during TRIG1,2 ON)

Change by cross key. Default value “0ms”

range: · 0ms-999ms(time)

Memory Setting for value change by parallel input.

Default value "OFF"

▲ Key

CH/ENT Key

CH/ENT Key:fix value

▼ Key

Confirm STB off

Check if the value is “OFF”. Default value “OFF”

If it is “ON”, change to “OFF”

CH/ENT Key:fix value

CH/ENT Key:fix value

CH/ENT Key:fix value

Change by cross key. Default value “ALL”

range: · 0.1ms-99.9ms(time)

· ALL(Lightings ON during TRIG1,2 ON)

Change by cross key. Default value “0ms”

range: · 0ms-999ms(time)

▲ Key

▲ Key

▼ Key

▼ Key

▼ Key

▲ Key

CH/ENT Key CH/ENT Key

CH/ENT Key

CH/ENT Key

▼ Key

No setting needed

No setting needed

Strobe setting

Change by cross key.

Default value “0.01ms”

range:0.01ms-5.00ms(time)

CH/ENT Key:fix value

▲ Key▼ Key

CH/ENT Key

▲ Key

Memory function setting

Memory Setting for value change by parallel input.

Default value "OFF"

Data saving(2s)

Invalid period of trigger input

ON

OFF

ON

OFF

Light ON

Light OFF

This function applies only when using the external control.

“ON” : The data stored in FLASH(nonvolatile) memory.

Keep data even when the power turned off. 2 sec

required for data saving.

Make interval at least 2 sec between “SAVE” signal

and next “TRIG” signal.

“OFF”: The data stored in RAM(volatile) memory.

Return to the last saving data when the power is

turned off.

Suitability for Use

s

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

Oct, 2014

D

OMRON Corporation

Industrial Automation Company

Contact: www.ia.omron.com

Tokyo, JAPAN

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

Regional Headquarters

Loading...

Loading...