5-9

5-7 Emergency Messages

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

5

EtherCAT Communications

5-7 Emergency Messages

When an error or warning occurs in a OMNUC G5-series Servo Drive, an emergency message

is sent to the master using mailbox communications. An emergency message is not sent for a

communications error.

You can select whether to send emergency messages setting Diagnosis history (10F3 hex).

The default setting is to not send emergency messages. (10F3 hex, Sub: 05 hex (Flags) = 0)

Set the sub-index 05 hex (Flags) in object 10F3 hex to 1 every time the power is turned ON to

send emergency messages.

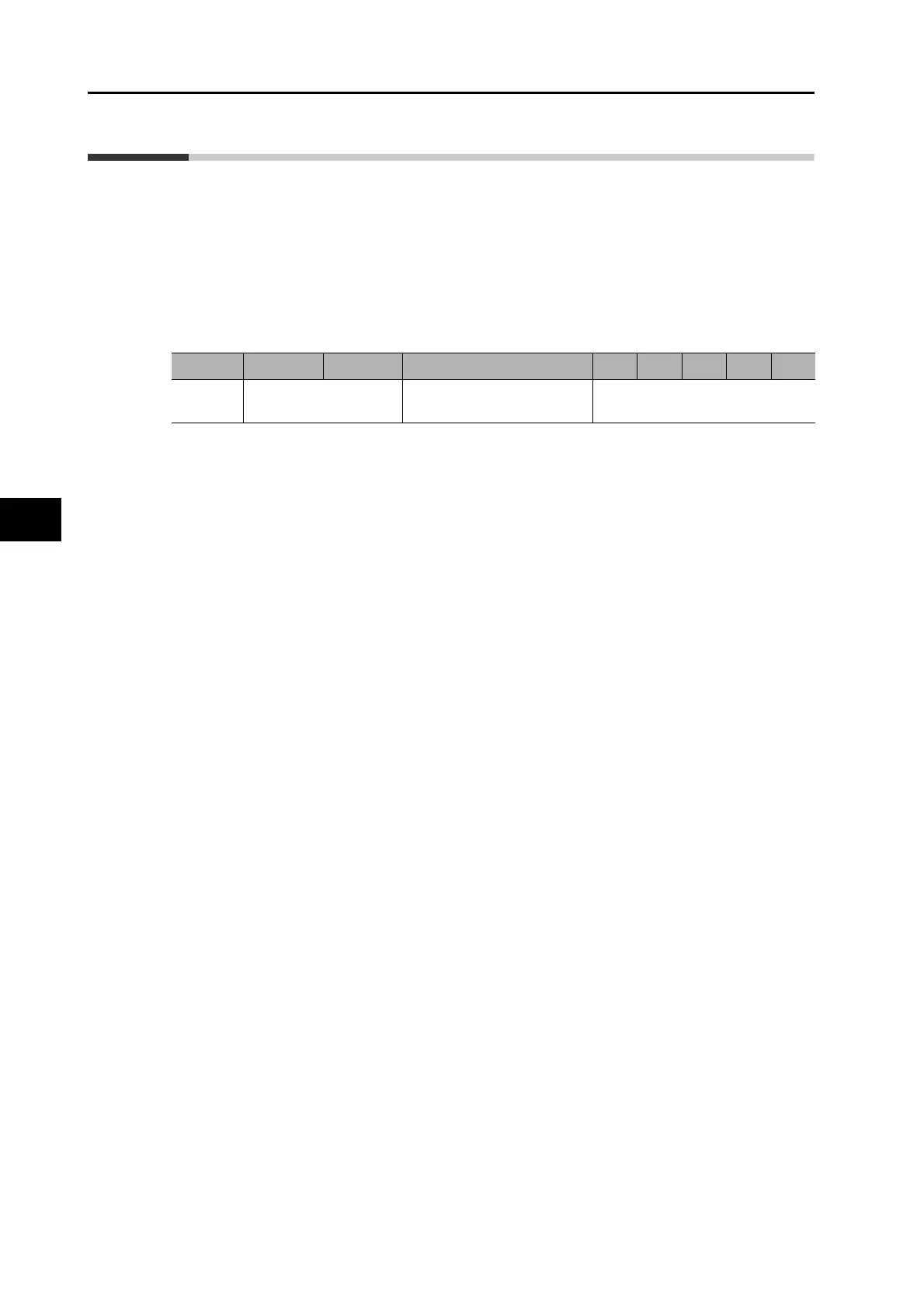

Emergency messages consist of 8 bytes of data.

*1 Error codes (FF00 hex to FFFF hex) in the manufacturer-specific area are used.

Note: For details on errors and warnings of the Servo Drive, refer to Chapter 12 Troubleshooting and

Maintenance.

Byte 0 1 2 3 4 5 6 7

Contents

Emergency Error

Code

*1

Error register (1001 hex)

Manufacturer Specific Error Field

(reserved)