12 - 33

12 Troubleshooting and Maintenance

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

12-4 Troubleshooting

12

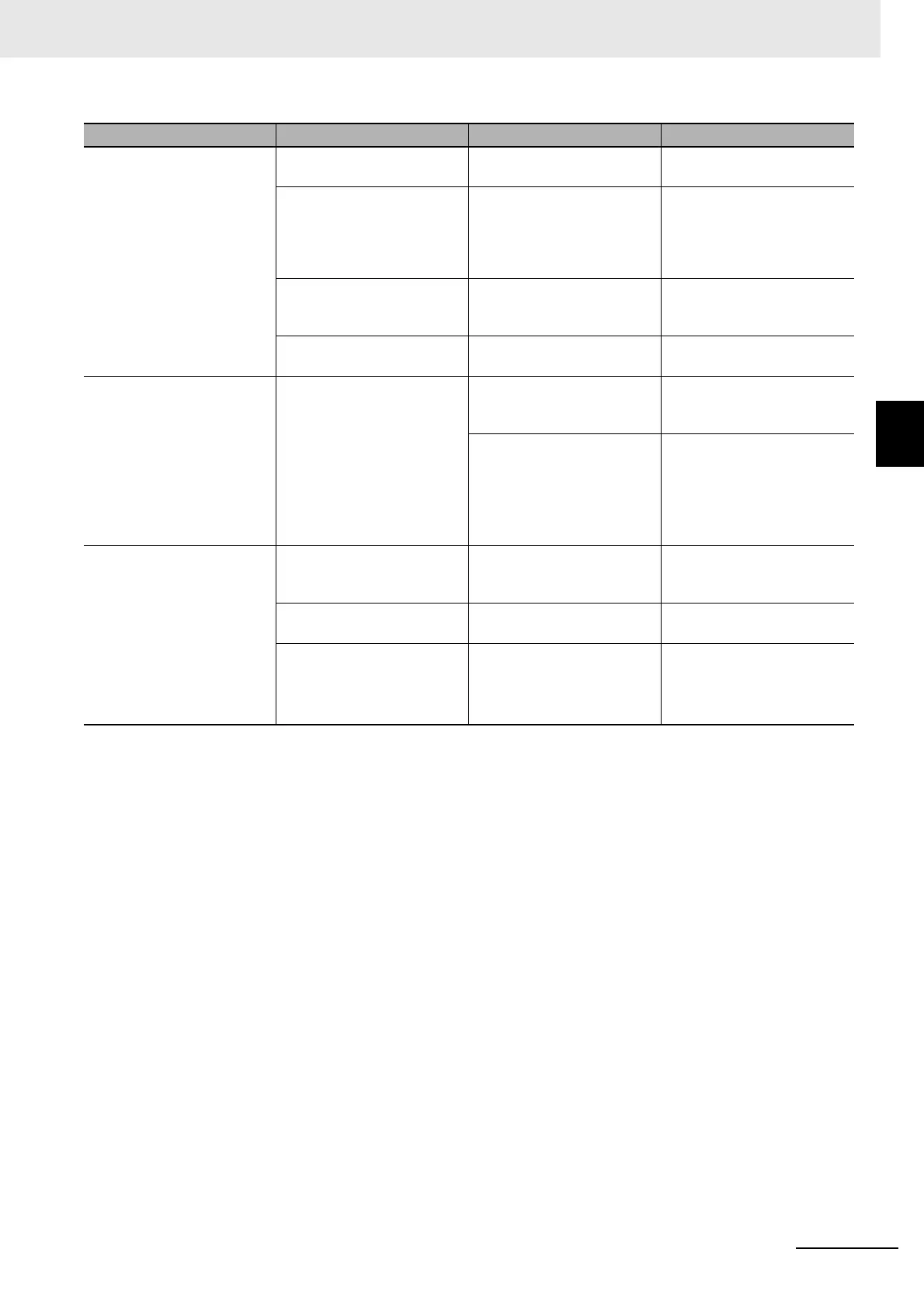

12-4-3 Troubleshooting Using the Operation State

Overshooting at startup or

when stopping

The Position Loop Gain 1

(3100 hex) is too large.

Review the setting of object

3100 hex.

Adjust the gain to prevent

overshooting.

The Speed Loop Gain 1

(3101 hex) and the Speed

Loop Integral Time Constant

1 (3102 hex) are balanced

incorrectly.

Review the set values of

objects 3101 hex and

3102 hex.

Use the CX-Drive or the

analog monitor to measure

the response and adjust the

gain.

The machine rigidity set by

realtime autotuning is

incorrect.

Review the setting of the

machine rigidity.

Match the machine rigidity

setting to the load rigidity.

The set mass ratio differs

from the load.

Review the set value of the

Mass Ratio (3004 hex).

Adjust the set value of object

3004 hex with the load.

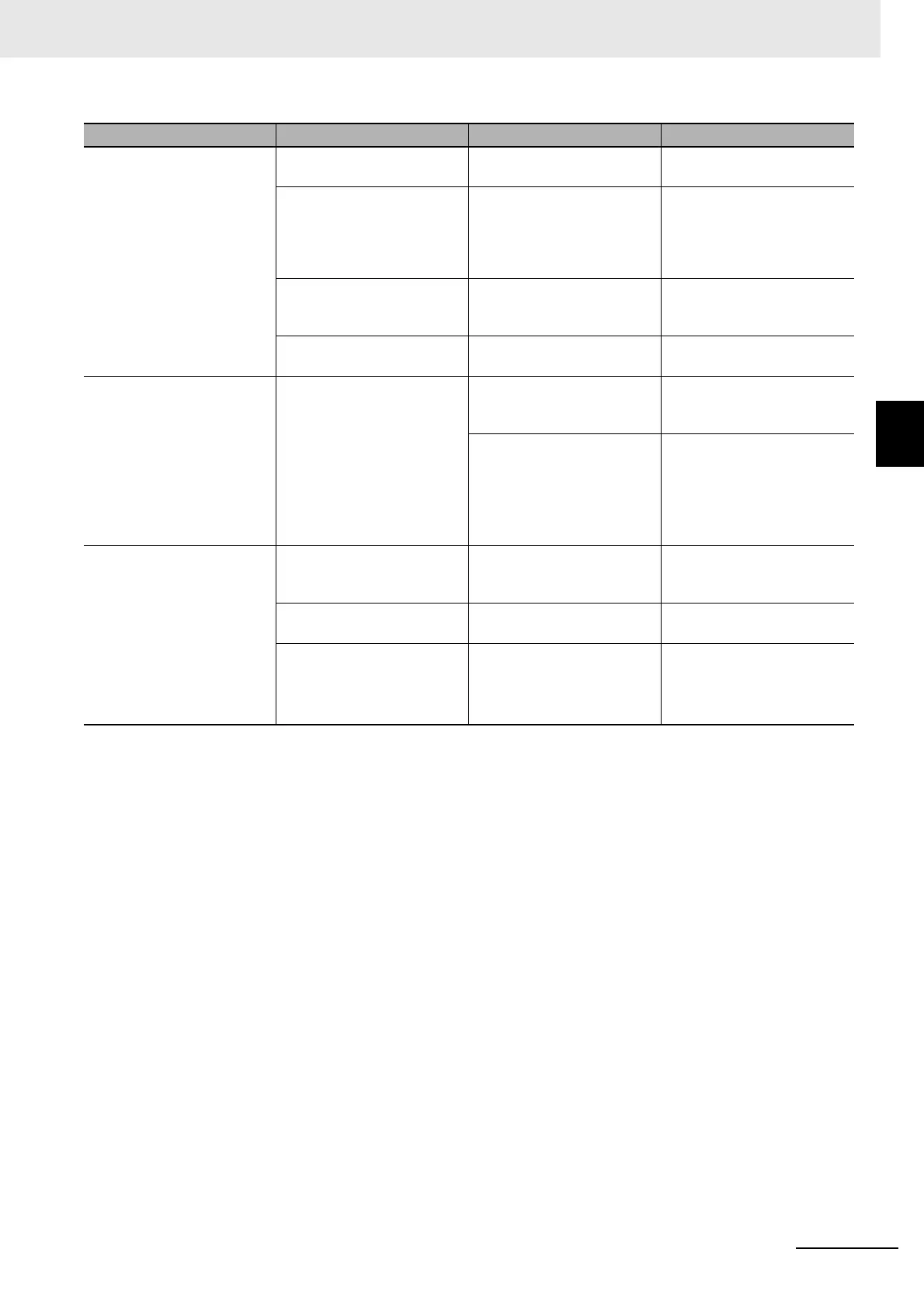

Vibration is occurring at the

same frequency as the

power supply.

Inductive noise is occurring. Check to see if the drive

control signal lines are too

long.

Shorten the control signal

lines.

Check to see if the control

signal lines and power

supply lines are bound

together.

• Separate control signal

lines from power supply

lines.

• Use a low-impedance

power supply for control

signals.

The position is misaligned.

(Position misalignment

occurs without an error being

output.)

The coupling of the

mechanical system is

insufficient.

Check to see if the

mechanical system is

misaligned.

Correct the coupling of the

mechanical system.

The gain is wrong. – Check if manual tuning can

achieve proper adjustment.

The load mass is too large. • Check the load mass.

• Check the motor speed.

• The dynamic brake

resistance is disconnected.

• Review the load mass.

• Replace the motor and

Servo Drive with proper

ones.

Symptom Probable cause Items to check Measures

Loading...

Loading...