T

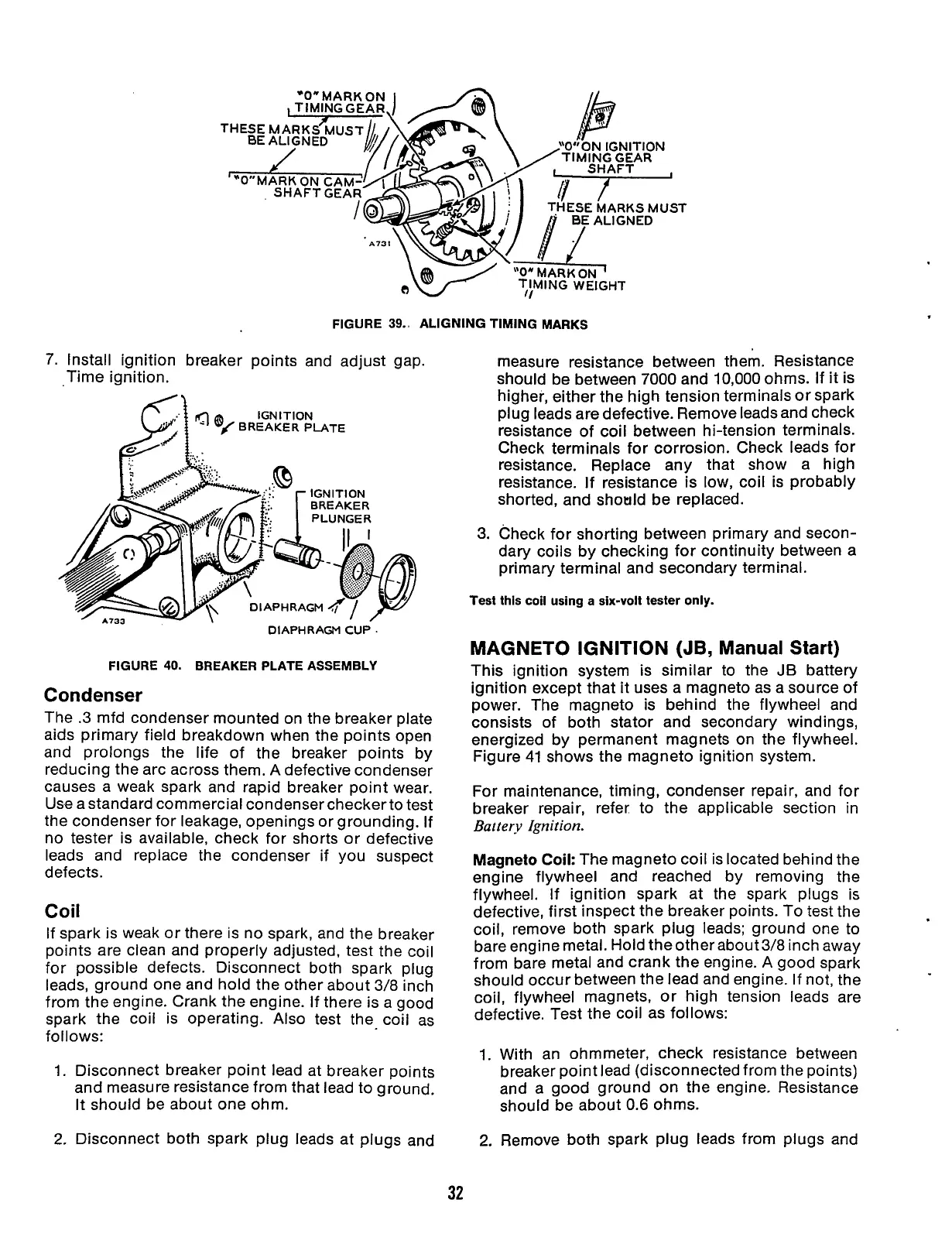

FIGURE 39.. ALIGNING TIMING MARKS

7.

Install ignition breaker points and adjust gap.

Time ignition.

-,

-"

DIAPHRAGM

CUP

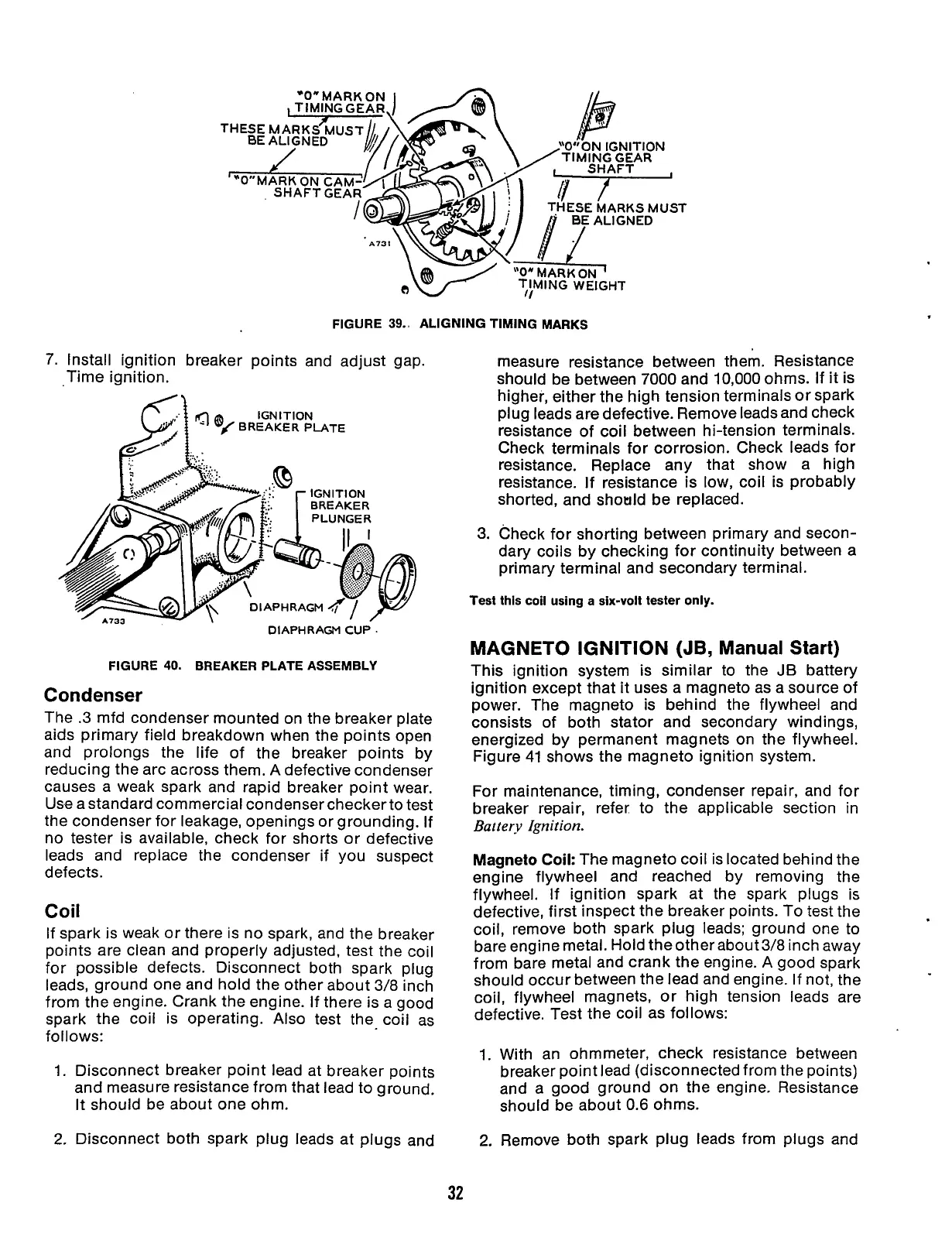

FIGURE

40.

BREAKER PLATE ASSEMBLY

Condenser

The .3 mfd condenser mounted on the breaker plate

aids primary field breakdown when the points open

and prolongs the life of the breaker points by

reducing the arc across them. A defective condenser

causes a weak spark and rapid breaker point wear.

Use a standard commercial condenser checker to test

the condenser for leakage, openings or grounding. If

no tester is available, check for shorts or defective

leads and replace the condenser if you suspect

defects.

Coil

If spark is weak or there is no spark, and the breaker

points are clean and properly adjusted, test the coil

for possible defects. Disconnect both spark plug

leads, ground one and hold the other about 3/8 inch

from the engine. Crank the engine.

If

there is a good

spark the coil is operating. Also test the coil as

follows:

1.

2.

Disconnect breaker point lead at breaker points

and measure resistance from that lead to ground.

It should be about one ohm.

Disconnect both spark plug leads at plugs and

measure resistance between them. Resistance

should be between

7000

and

10,000

ohms. If it is

higher, either the high tension terminals or spark

plug leads are defective. Remove leads and check

resistance of coil between hi-tension terminals.

Check terminals for corrosion. Check leads for

resistance. Replace any that show a high

resistance. If resistance

is

low, coil is probably

shorted, and should be replaced.

3.

Check for shorting between primary and secon-

dary coils by checking for continuity between a

primary terminal and secondary terminal.

Test this coil

using

a

six-volt tester

only.

MAGNETO IGNITION

(JB,

Manual Start)

This ignition system is similar to the

JB

battery

ignition except that it uses a magneto as a source of

power. The magneto is behind the flywheel and

consists of both stator and secondary windings,

energized by permanent magnets on the flywheel.

Figure

41

shows the magneto ignition system.

For maintenance, timing, condenser repair, and for

breaker repair, refer to the applicable section in

Battery Ignition.

Magneto Coil:

The magneto coil is located behind the

engine flywheel and reached by removing the

flywheel. If ignition spark at the spark plugs is

defective, first inspect the breaker points.

To

test the

coil, remove both spark plug leads; ground one to

bare engine metal. Hold theotherabout3/8 inch away

from bare metal and crank the engine. A good spark

should occur between the lead and engine. If not, the

coil, flywheel magnets,

or

high tension leads are

defective. Test the coil as follows:

1.

2.

With an ohmmeter, check resistance between

breaker point lead (disconnected from the points)

and a good ground on the engine. Resistance

should be about

0.6

ohms.

Remove both spark plug leads from plugs and

32

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...