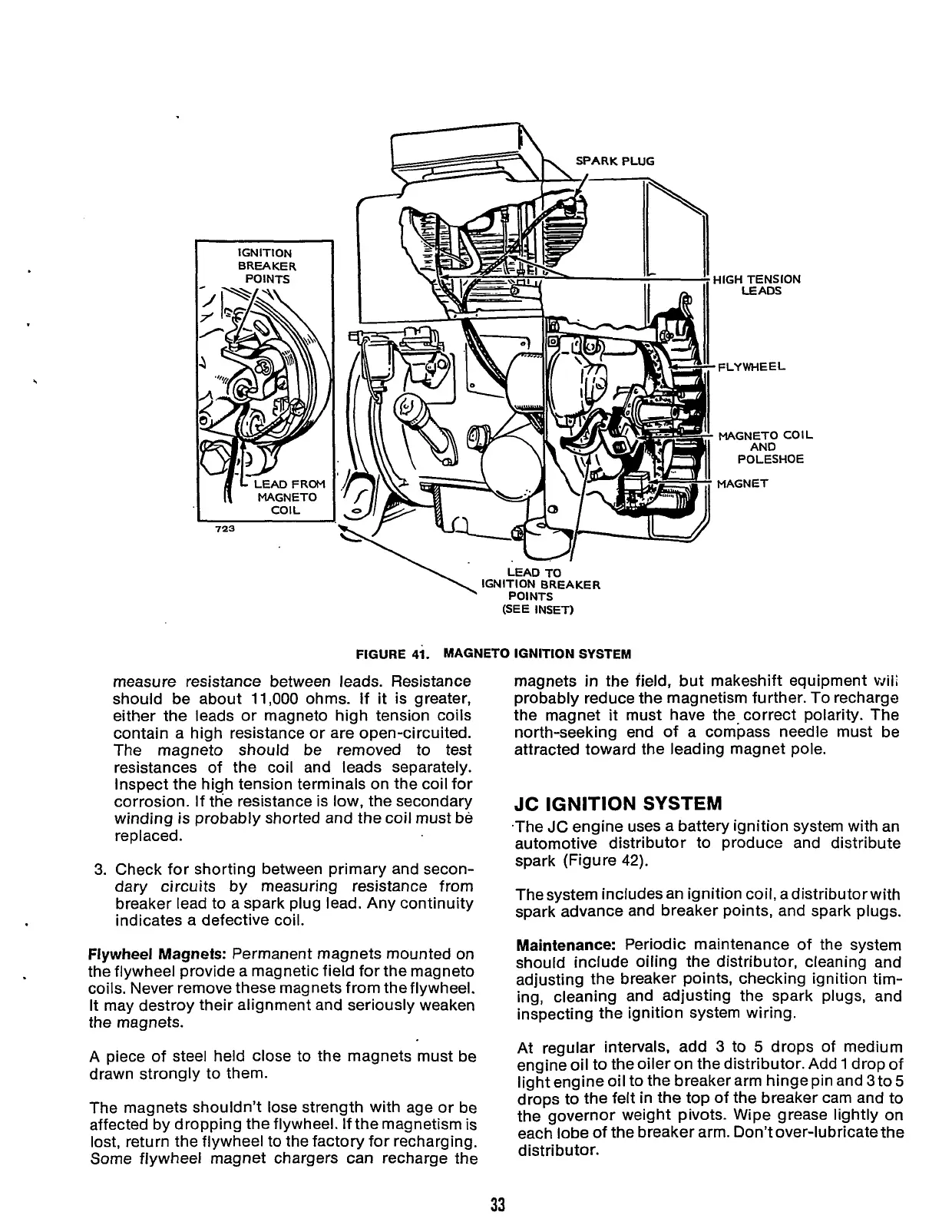

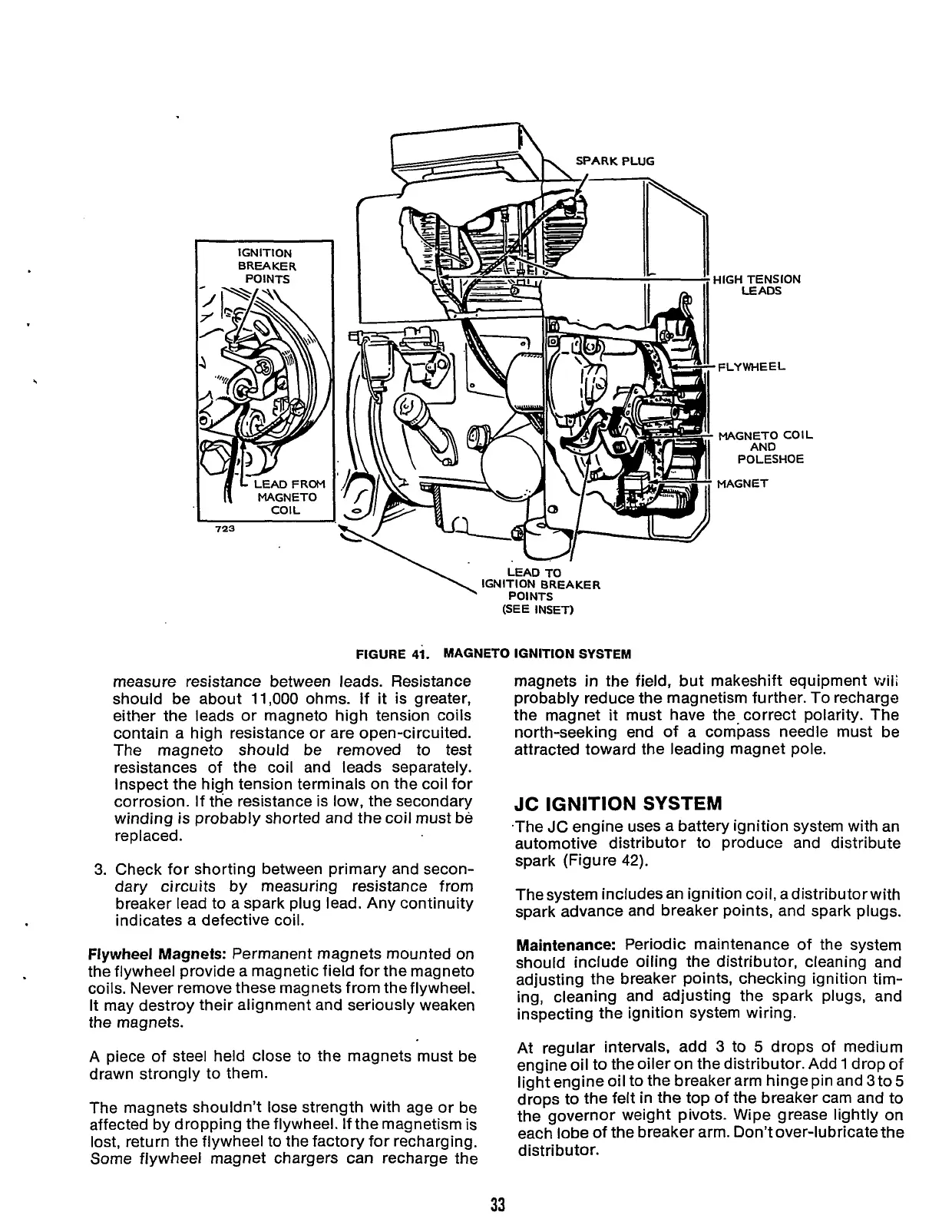

BREAKER

POINTS

3.

(SEE INSET)

FIGURE

41.

MAGNETO IGNITION SYSTEM

measure resistance between leads. Resistance

should be about

11,000

ohms. If it is greater,

either the leads

or

magneto high tension coils

contain a high resistance or are open-circuited.

The magneto should be removed to test

resistances of the coil and leads separately.

Inspect the high tension terminals on the coil for

corrosion. If the resistance is low, the secondary

winding is probably shorted and the coil must be

replaced.

Check for shorting between primary and secon-

dary circuits by measuring resistance from

breaker lead to a spark plug lead. Any continuity

indicates a defective coil.

Flywheel

Magnets:

Permanent magnets mounted on

the flywheel provide a magnetic field for the magneto

coils. Never remove these magnets from the flywheel.

It may destroy their alignment and seriously weaken

the magnets.

A

piece of steel held close to the magnets must be

drawn strongly to them.

The magnets shouldn't lose strength with age

or

be

affected by dropping the flywheel.

If

the magnetism is

lost, return the flywheel to the factory for recharging.

Some flywheel magnet chargers can recharge the

magnets

in

the field, but makeshift equipment

wili

probably reduce the magnetism further.

To

recharge

the magnet

it

must have the-correct polarity. The

north-seeking end of a compass needle must be

attracted toward the leading magnet pole.

JC

IGNITION

SYSTEM

.The

JC

engine uses a battery ignition system with an

automotive distributor to produce and distribute

spark (Figure

42).

The system includes an ignition coil, adistributorwith

spark advance and breaker points, and spark plugs.

Maintenance:

Periodic maintenance of the system

should include oiling the distributor, cleaning and

adjusting the breaker points, checking ignition tim-

ing, cleaning and adjusting the spark plugs, and

inspecting the ignition system wiring.

At regular intervals, add

3

to

5

drops of medium

engine oil to the oiler on the distributor. Add

1

drop of

light engine oil to the breaker arm hinge pin and

3

to

5

drops to the felt in the top of the breaker cam and to

the governor weight pivots. Wipe grease lightly on

each lobe of the breaker arm. Don't over-lubricate the

distributor.

33

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...