17

1’

.

io

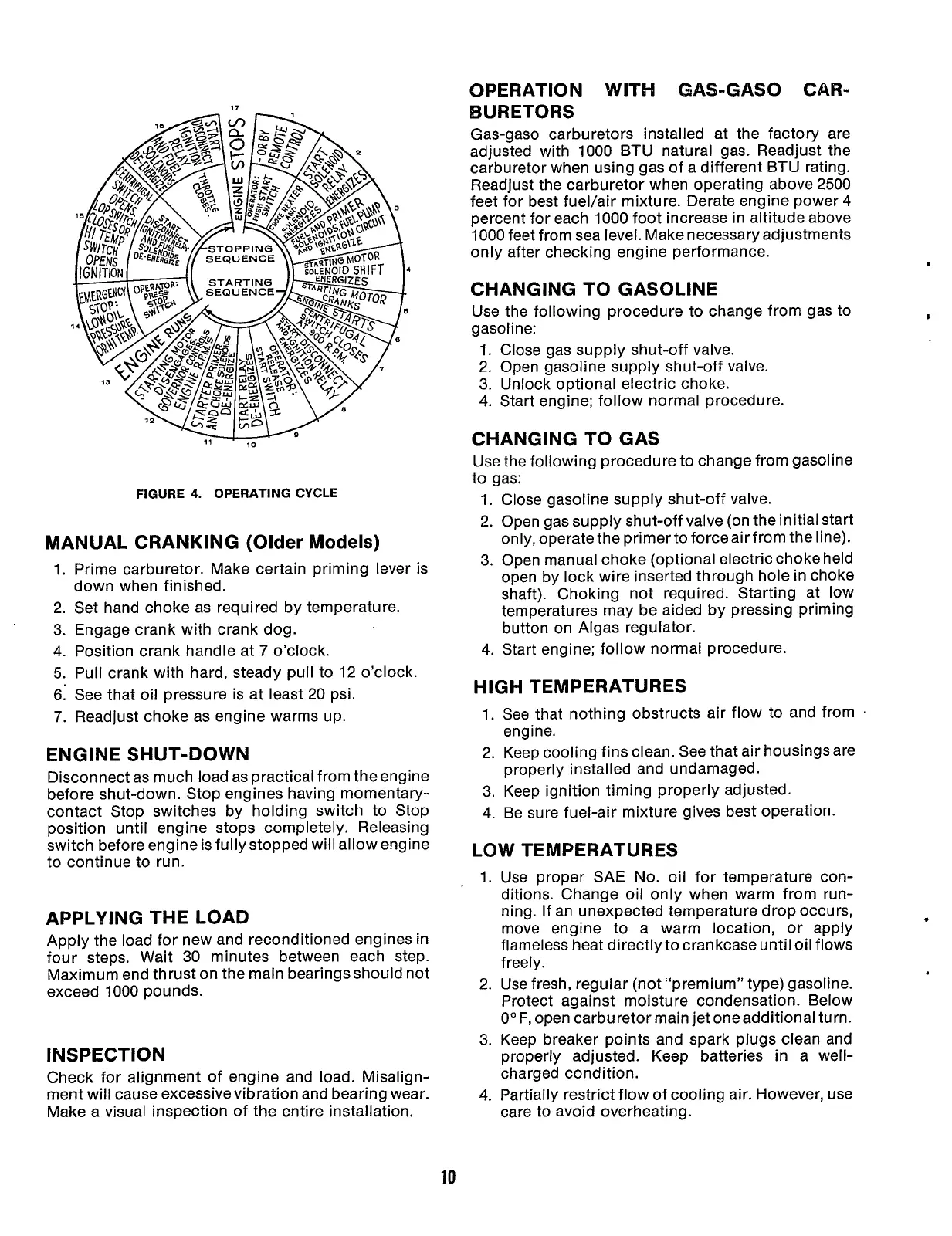

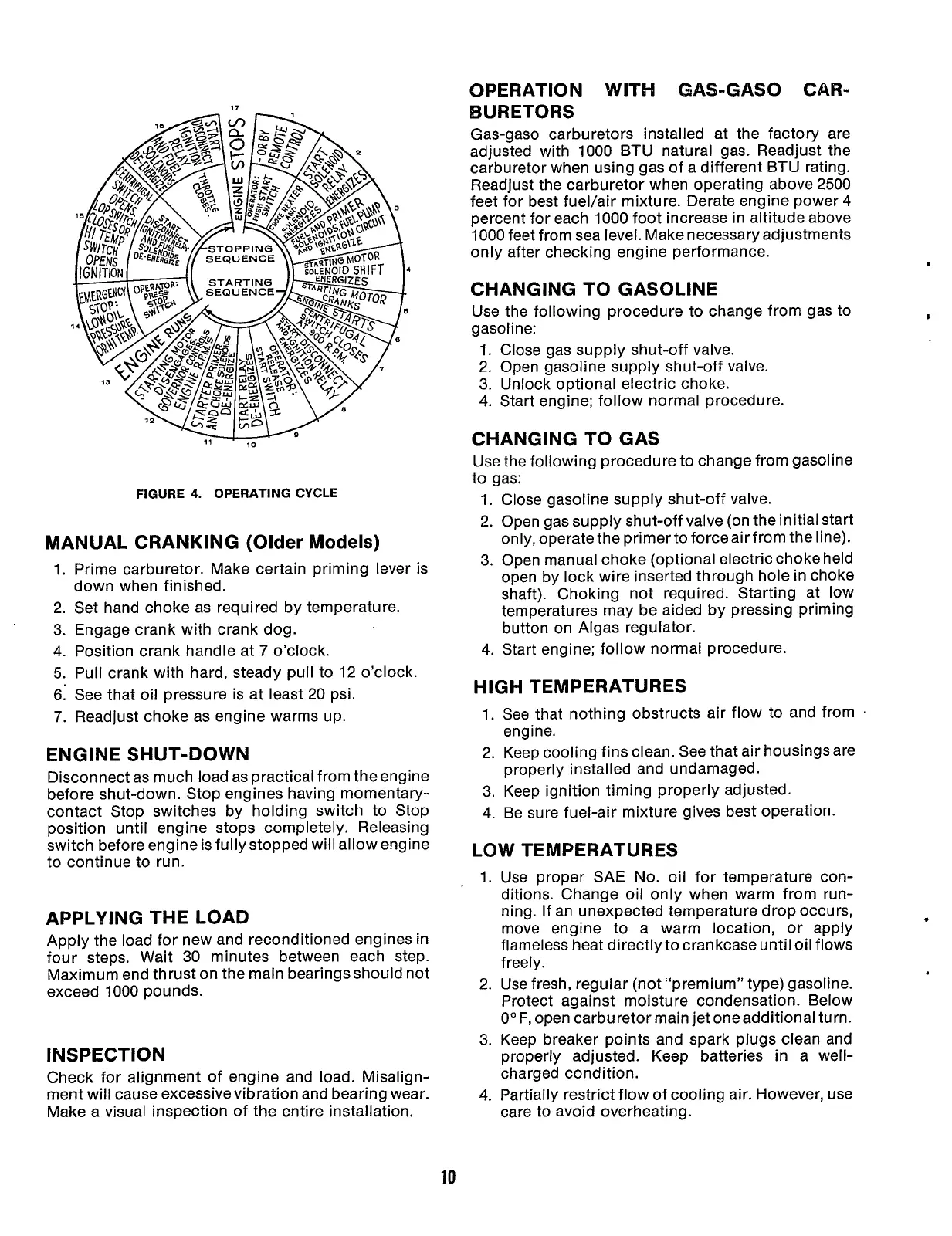

FIGURE

4.

OPERATING CYCLE

MANUAL CRANKING (Older Models)

1.

2.

’

3.

4.

5.

6.

7.

Prime carburetor. Make certain priming lever is

down when finished.

Set hand choke as required by temperature.

Engage crank with crank dog.

Position crank handle at

7

o’clock.

Pull crank with hard, steady pull to

12

o’clock.

See that oil pressure is at least

20

psi.

Readjust choke as engine warms up.

ENGINE SHUT-DOWN

Disconnect as much load as practical from the engine

before shut-down. Stop engines having momentary-

contact Stop switches by holding switch to Stop

position until engine stops completely. Releasing

switch before engine isfullystopped will allow engine

to continue to run.

APPLYING THE LOAD

Apply the load for new and reconditioned engines in

four steps. Wait

30

minutes between each step.

Maximum end thrust on the main bearingsshould not

exceed

1000

pounds.

INSPECTION

Check for alignment of engine and load. Misalign-

ment will cause excessive vibration and bearing wear.

Make

a

visual inspection of the entire installation.

OPERATION WITH

GAS-GAS0

CAR-

BURETORS

Gas-gas0 carburetors installed at the factory are

adjusted with

1000

BTU natural gas. Readjust the

carburetor when using gas of a different BTU rating.

Readjust the carburetor when operating above

2500

feet for best fuel/air mixture. Derate engine power

4

percent for each

1000

foot increase in altitude above

1000

feet from sea level. Make necessary adjustments

only after checking engine performance.

CHANGING TO GASOLINE

Use the following procedure to change from gas to

gasoline:

1.

Close gas supply shut-off valve.

2.

Open gasoline supply shut-off valve.

3.

Unlock optional electric choke.

4. Start engine; follow normal procedure.

CHANGING TO GAS

Use the following procedure to change from gasoline

to gas:

1.

Close gasoline supply shut-off valve.

2.

Open gas supply shut-off valve (on the initial start

only, operatethe primerto forceair from the line).

3.

Open manual choke (optional electric choke held

open by lock wire inserted through hole in choke

shaft). Choking not required. Starting at low

temperatures may be aided by pressing priming

button on Algas regulator.

4.

Start engine; follow normal procedure.

HIGH TEMPERATURES

1.

See that nothing obstructs air flow to and from

engine.

2.

Keep cooling fins clean. See that air housingsare

properly installed and undamaged.

3.

Keep ignition timing properly adjusted.

4.

Be sure fuel-air mixture gives best operation.

LOW TEMPERATURES

1.

2.

3.

4.

Use proper SAE

No.

oil for temperature con-

ditions. Change oil only when warm from run-

ning. If an unexpected temperature drop occurs,

move engine to a warm location, or apply

flameless heat directly to cran kcase until oil flows

freely.

Use fresh, regular (not “premium” type) gasoline.

Protect against moisture condensation. Below

0”

F,

open carburetor main jet oneadditional turn.

Keep breaker points and spark plugs clean and

properly adjusted. Keep batteries

in

a well-

charged condition.

Partially restrict flow of cooling air. However, use

care to avoid overheating.

10

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...