STARTING

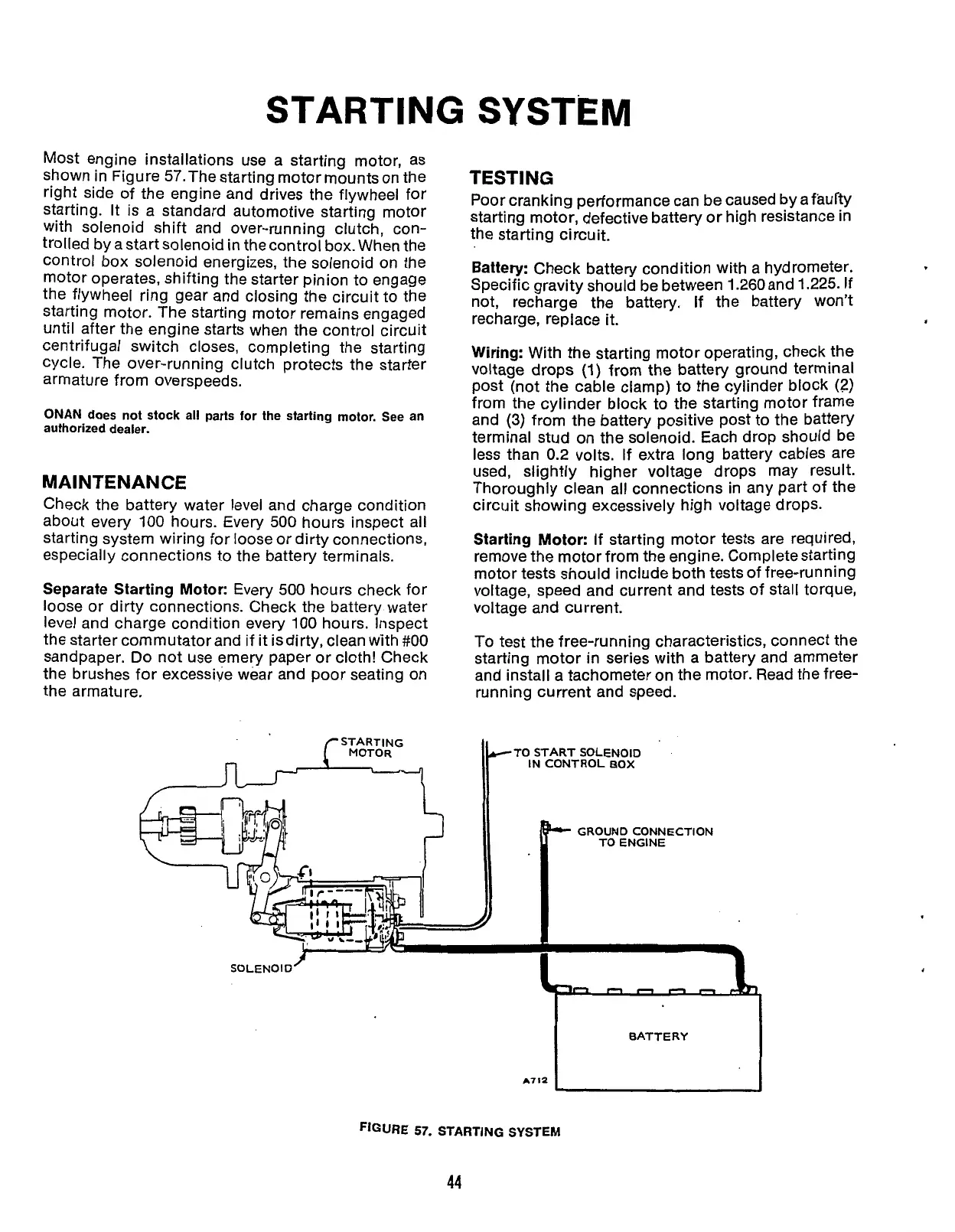

Most engine installations use a starting motor, as

shown in Figure 57.The starting motor mounts on the

right side of the engine and drives the flywheel for

starting. It is a standard automotive starting motor

with solenoid shift and over-running clutch, con-

trolled by a start solenoid

in

the control box. When the

control box solenoid energizes, the solenoid on the

motor operates, shifting the starter pinion to engage

the flywheel ring gear and closing the circuit to the

starting motor. The starting motor remains engaged

until after the engine starts when the control circuit

centrifugal switch closes, completing the starting

cycle. The over-running clutch protects the starter

armature from overspeeds.

ONAN does not stock all parts for the starting motor. See an

authorized dealer.

MAINTENANCE

Check the battery water level and charge condition

about every 100 hours. Every

500

hours inspect all

starting system wiring for loose or dirty connections,

especially connections to the battery terminals.

Separate Starting Motor:

Every

500

hours check for

loose or dirty connections. Check the battery water

level and charge condition every

100

hours. Inspect

the starter commutator and if it isdirty, clean with

#00

sandpaper.

Do

not use emery paper or cloth! Check

the brushes for excessive wear and poor seating on

the armature.

START

I

NG

MOTOR

TESTING

Poor cranking performance can be caused byafaurty

starting motor, defective battery or high resistance in

the starting circuit.

Battery:

Check battery condition with a hydrometer.

Specific gravity should be between 1.260 and 1.225. If

not, recharge the battery. If the battery won't

recharge, replace

it.

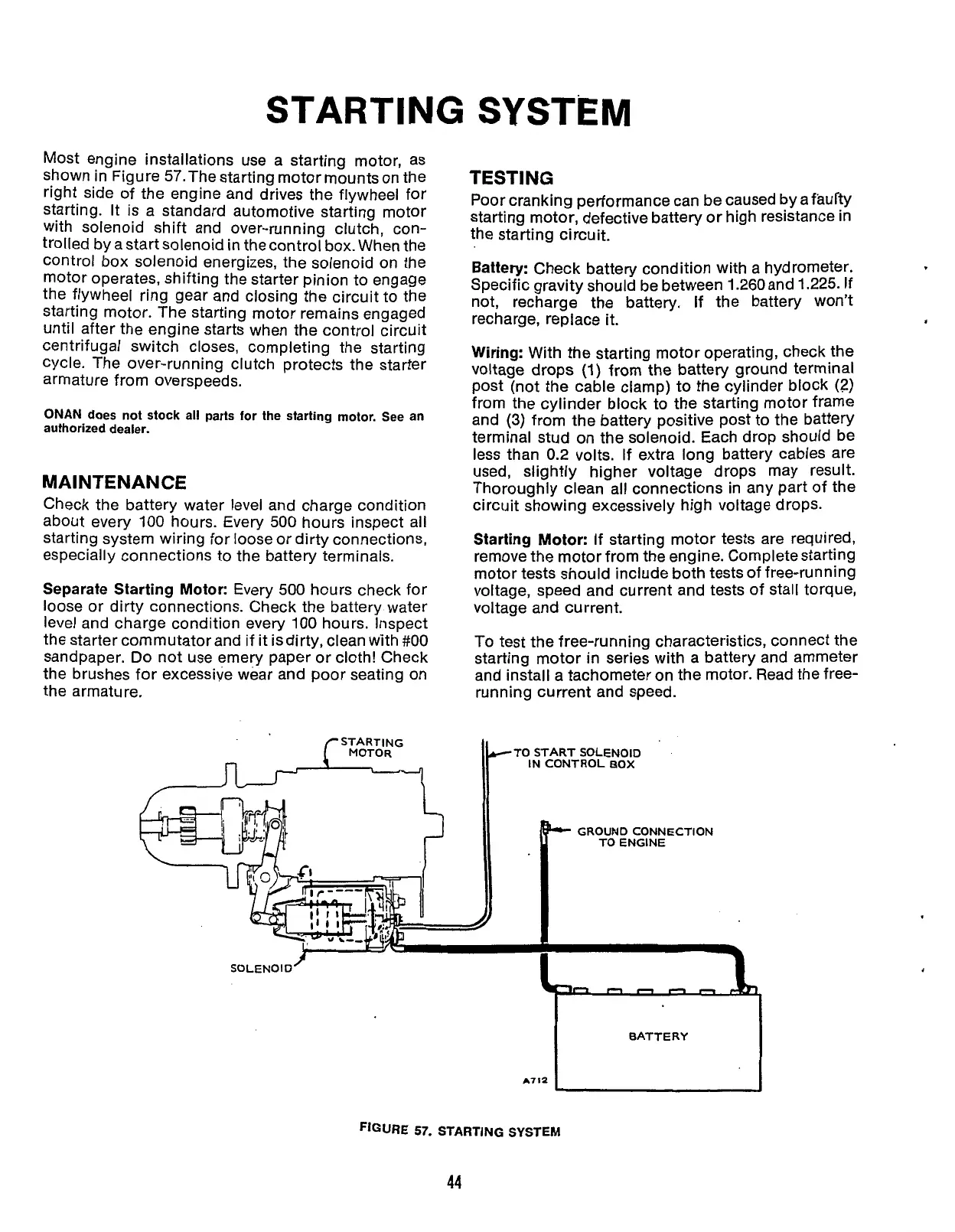

Wiring:

With the starting motor operating, check the

voltage drops

(1)

from the battery ground terminal

post (not the cable clamp) to the cylinder block

(2)

from the cylinder block to the starting motor frame

and

(3)

from the battery positive post to the battery

terminal stud on the solenoid. Each drop should be

less than

0.2

volts. If extra long battery cables are

used, slightly higher voltage drops may result.

Thoroughly clean all connections in any part of the

circuit showing excessively high voltage drops.

Starting Motor:

If starting motor tests are required,

remove the motor from the engine. Complete starting

motor tests should include both tests of free-running

voltage, speed and current and tests of stall torque,

voltage and current.

To

test the free-running characteristics, connect the

starting motor

in

series with a battery and ammeter

and install a tachometer on the motor. Read the free-

running current and speed.

TO

START

SOLENOID

IN

CONTROL

BOX

t

,

FIGURE

57.

STARTING

SYSTEM

44

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...