NS ION

TANK

ENGINE

EXHAUST

MAN

I

FO

LD

EXHAlJST

LINE

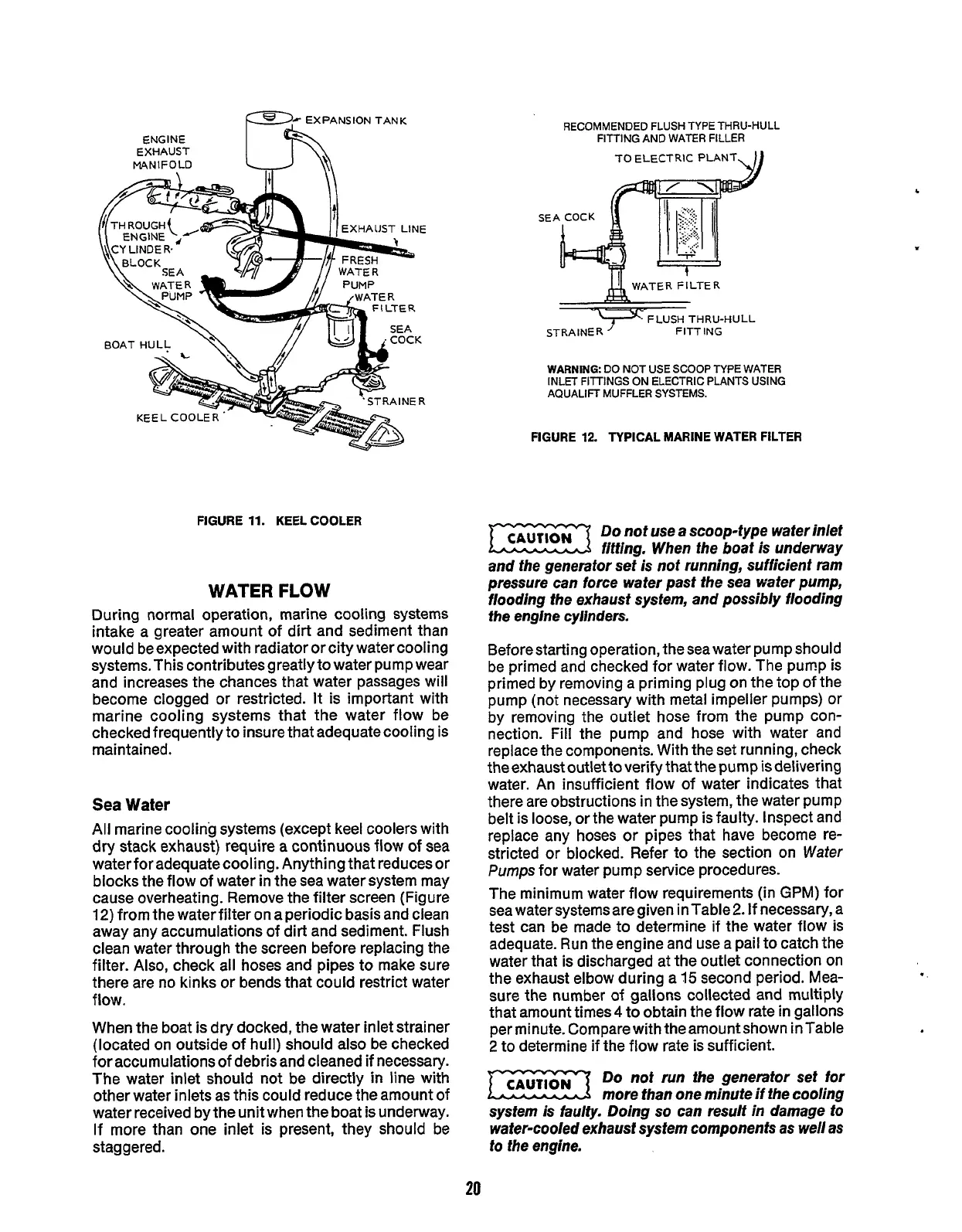

FIGURE

11.

KEEL COOLER

WATER

FLOW

During normal operation, marine cooling systems

intake a greater amount of dirt and sediment than

would beexpected with radiator or city water cooling

systems. This contributes greatly to water pump wear

and increases the chances that water passages will

become clogged or restricted.

It

is important with

marine cooling systems that the water flow be

checked frequently to insure that adequatecooling is

maintained.

Sea

Water

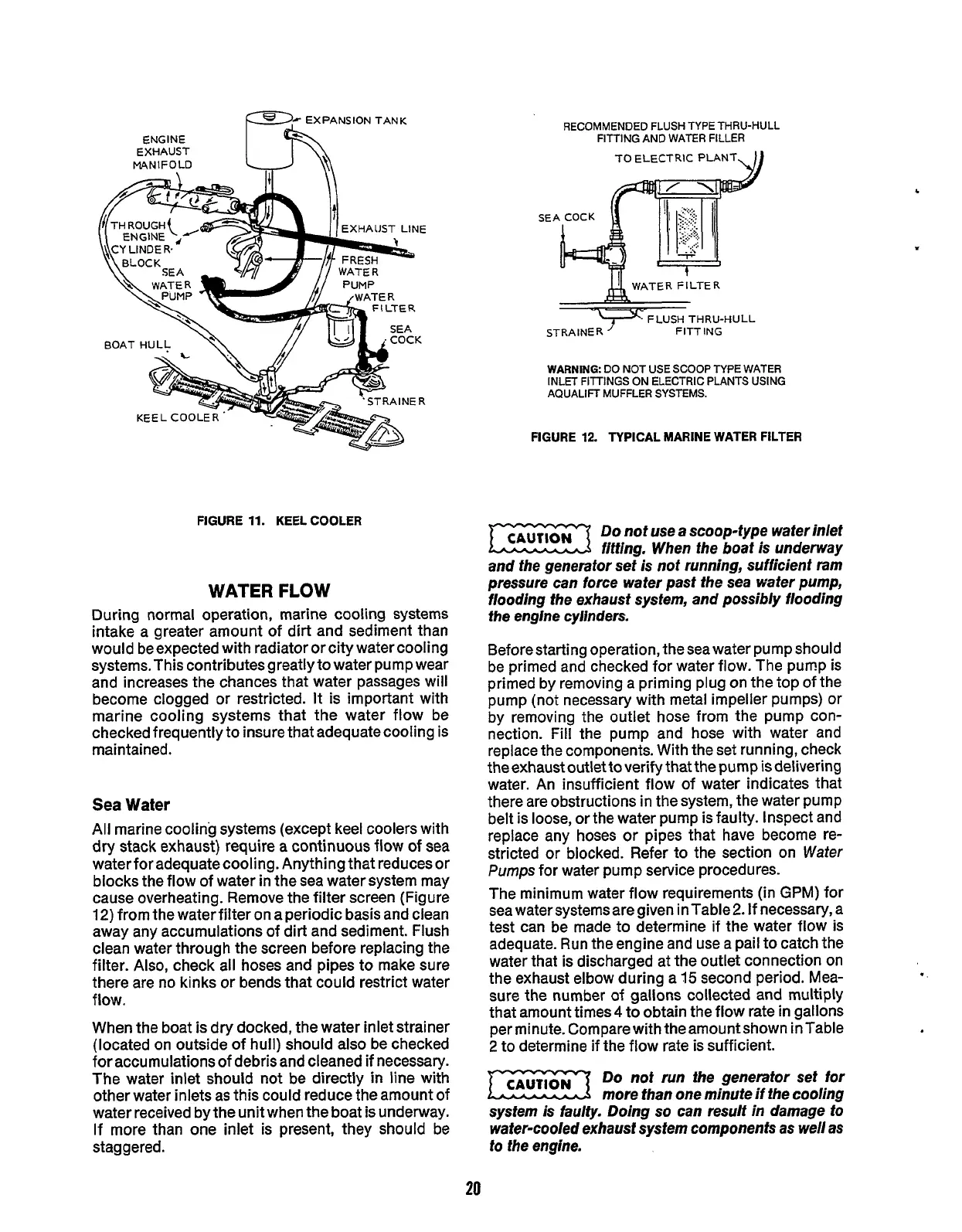

All marine cooling systems (except keel coolers with

dry stack exhaust) require a continuous flow of

sea

water for adequate cooling. Anything that reduces or

blocks the flow of water in the sea water system may

cause overheating. Remove the filter screen (Figure

12)

from the water filter on a periodic basis and clean

away any accumulations of dirt and sediment. Flush

clean water through the screen before replacing the

filter. Also, check all hoses and pipes to make sure

there are no kinks or bends that could restrict water

flow.

When the boat is dry docked, the water inlet strainer

(located on outside of hull) should also be checked

for accumulations of debris and cleaned if necessary.

The water inlet should not be directly

in

line with

other water inlets as this could reduce the amount of

water received bythe unit when the boat is underway.

If

more than one inlet is present, they should

be

staggered.

RECOMMENDED FLUSH TYPE THRU-HULL

FITTING AND WATER FILLER

TO

ELECTRIC PLANT

FLUSH THRU-HULL

FlTT ING

WARNING.

DO

NOT USE SCOOP TYPE WATER

INLET FITTINGS ON ELECTRIC PLANTS USING

AQUALIFT MUFFLER SYSTEMS.

FIGURE

12.

TYPICAL MARINE WATER FILTER

DO

not use a scoop-type wafer inlet

lzz3

fiffing. When the boat

is

underway

and fhe generafor sef

is

not running, sufficienf ram

pressure can force wafer past the sea wafer pump,

flooding the exhaust system, and possibly flooding

the

engine cylinders.

Beforestarting operation, theseawater pump should

be primed and checked for water flow. The punp is

primed by removing a priming plug on the top of the

pump (not necessary with metal impeller pumps) or

by removing the outlet hose from the pump con-

nection. Fill the pump and hose with water and

replace the components. With the set running, check

theexhaust outlet to verify that the pump is delivering

water. An insufficient flow

of

water indicates that

there are obstructions in the system, the water pump

belt is loose, or the water pump is faulty. Inspect and

replace any hoses or pipes that have become

re-

stricted or blocked. Refer to the section on

Water

Pumps

for water pump service procedures.

The minimum water flow requirements (in

GPM)

for

sea water systems are given inTable2. If necessary, a

test can be made to determine if the water flow is

adequate. Run the engine and use a pail to catch the

water that is discharged at the outlet connection on

the exhaust elbow during a

15

second period. Mea-

sure the number

of

gallons collected and multiply

that amount times

4

to obtain the flow rate in gallons

per minute. Compare with theamount shown inTable

2

to determine if the flow rate is sufficient.

Do nof run the generator set for

Ex3

more fhan one minute if the cooling

sysfem

is

fauify. Doing

so

can resuif in damage

to

water-cooled exhaust sysfem componenfs

as

well as

to the engine.

CAUT,ON

L

20

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...