WATER

PUMPS

#132-0110

and

#132-0074

Pumps #132-0110 and #132-0074 are centrifugal

pumps with metal impellers (Figure 19).

Disassembly

1.

2.

3.

4.

Remove the water inlet fitting, drive belt pulley,

cover screws, and pump cover gasket.

Unscrew the threaded impeller from the pump

shaft by turning the impeller

in

a counterclock-

wise direction (when facing impeller).

Slide the seal seat, wear face, and bellows

assembly

off

the shaft. Loosen the clamp screw

and slide the pump body

off

the pedestal.

Remove the bearing lock ring and drive the shaft

and bearing assembly out of the pedestal. The

bearing is press fit on the shaft and comes

off

in

one integral part. The bearing is packed with

a

lifelong lubricant and is sealed at each end.

Assembly

i

Replace all worn components such as bearings,

seals, wear face, and impeller and use a new cover

gasket. Assembly sequence is the reverse of the dis-

assembly procedure.

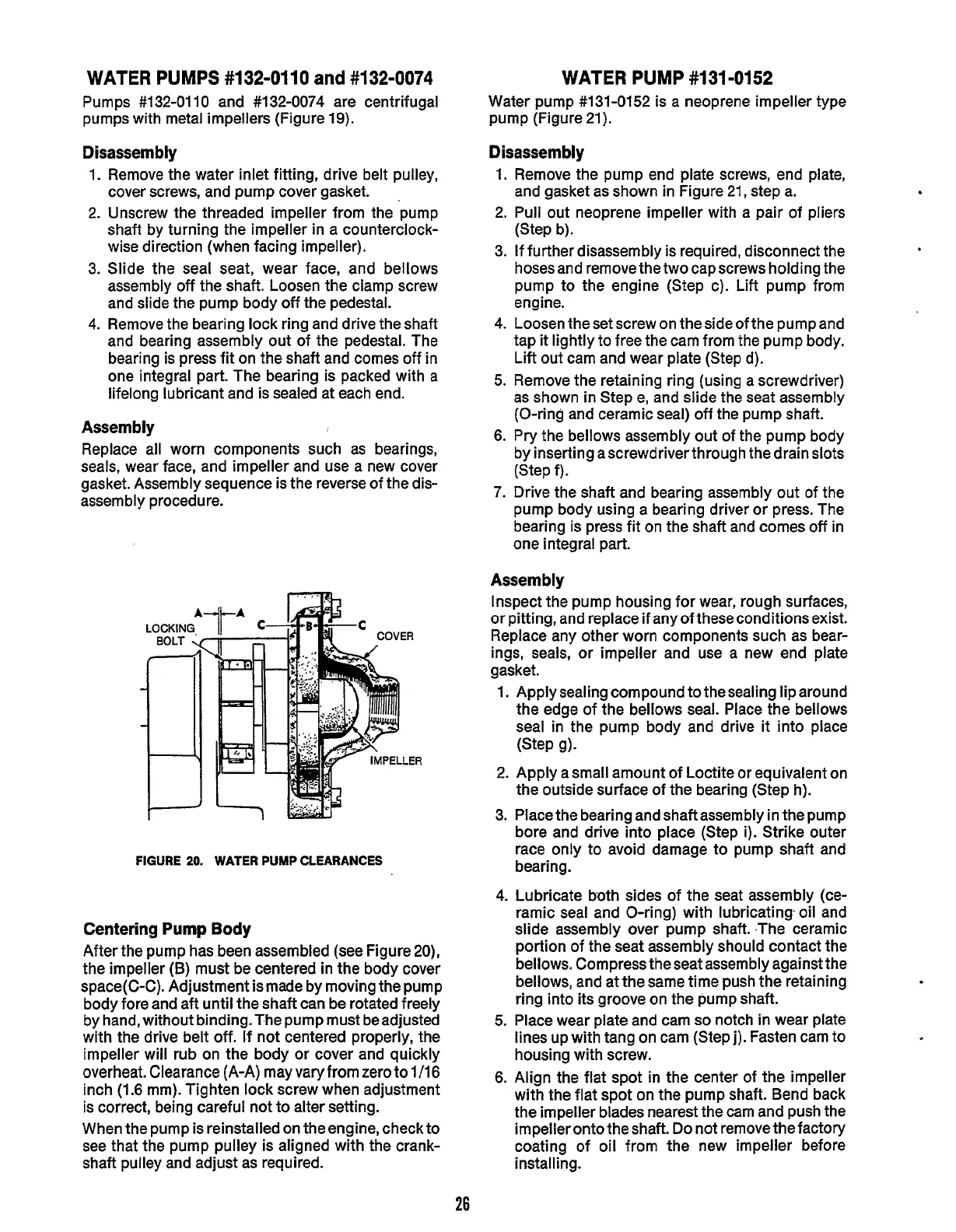

FIGURE

20.

WATER

PUMP

CLEARANCES

Centering

Pump

Body

After the pump has been assembled (see Figure

20),

the impeller

(B)

must be centered in

the

body cover

space(C-C). Adjustment ismade by moving the pump

body fore and aft until the shaft can be rotated freely

by hand, without binding.The pump must beadjusted

with the drive belt

off.

If not centered properly, the

impeller

will

rub on the body or cover and quickly

overheat. Clearance (A-A) may vary from zero

to

1/16

inch (1.6 mm). Tighten lock screw when adjustment

is correct, being careful not to alter setting.

When the pump is reinstalled on the engine, checkto

see that the pump pulley is aligned with the crank-

shaft pulley and adjust as required.

WATER

PUMP

#131-0152

Water pump #131-0152 is a neoprene impeller type

pump (Figure 21).

Disassembly

1.

2.

3.

4.

5.

6.

7.

Remove the pump end plate screws, end plate,

and gasket as shown in Figure

21,

step a.

Pull out neoprene impeller with a pair of pliers

(Step b).

If further disassembly is required, disconnect the

hoses and remove the two cap screws holding the

pump to the engine (Step c). Lift pump from

engine.

Loosen the set screw on the side of

the

pump and

tap

it

lightly to free the cam from the pump body.

Lift

out cam and wear plate (Step d).

Remove the retaining ring (using a screwdriver)

as shown in Step e, and slide the seat assembly

(O-ring and ceramic seal)

off

the pump shaft.

Pry the bellows assembly out of the pump body

by inserting ascrewdriver through the drain slots

(Step f).

Drive the shaft and bearing assembly out of the

pump body using a bearing driver or press. The

bearing is press fit on the shaft and comes

off

in

one integral part.

Assembly

Inspect the pump housing for wear, rough surfaces,

or pitting, and replace if any of theseconditionsexist.

Replace any other worn components such as bear-

ings, seals, or impeller and use a new end plate

gasket.

1.

Apply sealing compound to the sealing lip around

the edge of the bellows seal. Place the bellows

seal in the pump body and drive

it

into place

2. Apply a small amount of Loctite or equivalent on

the outside surface

of

the bearing (Step h).

3. Place the bearing and shaft assembly in the pump

bore and drive into place (Step i). Strike outer

race only to avoid damage to pump shaft and

bearing.

4. Lubricate both sides of the seat assembly (ce-

ramic seal and O-ring) with lubricating oil and

slide assembly over pump shaft. ,The ceramic

portion of the seat assembly should contact the

bellows. Compress the seat assembly against the

bellows, and at the same time push the retaining

ring into its groove on the pump shaft.

5.

Place wear plate and cam

so

notch

in

wear plate

lines up with tang on cam (Step j). Fasten cam to

housing with screw.

6. Align

the

flat spot in the center of the impeller

with the flat spot on the pump shaft. Bend back

the impeller blades nearest the cam and push the

impeller onto the shaft.

Do

not remove the factory

coating of oil from the new impeller before

installing.

(Step 9)-

26

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...