OIL LINES

At overhaul time the rocker box oil line should be

flushed with fuel and a fine wire used to clean the

small holes, Figure

77.

Clean standpipe breather on

four cylinder engines.

Clean out all other oil lines and drillings with com-

pressed air whenever the engine is disassembled or

overhauled. The oil gauge passage may be reached

by removing the oil filter mounting plate.

External oil lines, the rocker box oil line, and the

internal oil line to the rear bearing are replaceable.

Restriction orifices are placed

in

theexternal oil lines

to regulate the quantity of oil delivered to the injec-

tion pump gearing and tappet and to the rocker arm

and valve train areas. Two orifices are located

in

the

Tee fitting at the injection pump, and one orifice is

located in the inlet fitting to each cylinder head.

To

prevenf injection pump or valve

train damage from lack of iubrica-

fion,

ensure fhaf ail restriction orifices are kept open.

Cleaning can be done using

a

fine wire or drill bit and

compressed air.

0.028 inch size at heads

(0.71

mm)

0.046

inch size at Tee

(1

.I

7

mm)

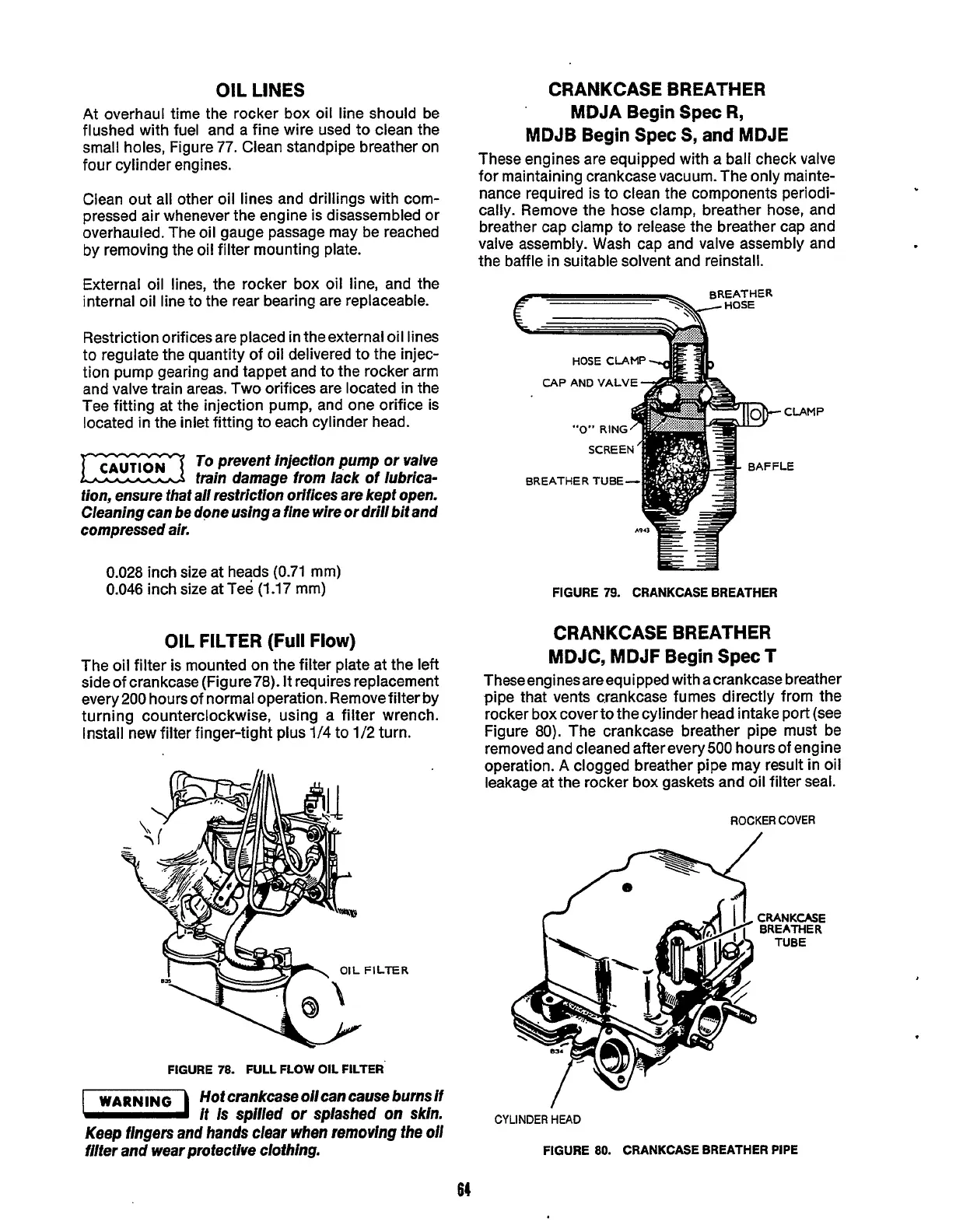

OIL FILTER (Full Flow)

The oil filter is mounted on the filter plate at the left

side of crankcase (Figure78). It requires replacement

every 200 hours of normal operation. Remove filter by

turning counterclockwise, using a filter wrench.

Install new filter finger-tight plus

1/4

to

1/2

turn.

FILTER

FIGURE

78.

FULL FLOW OIL FILTER

Hot crankcase

011

can cause burns if

if is spilled

or

splashed on skin.

Keep flngers and hands clear when removing

fhe

oil

filter and wear profecfive clothing.

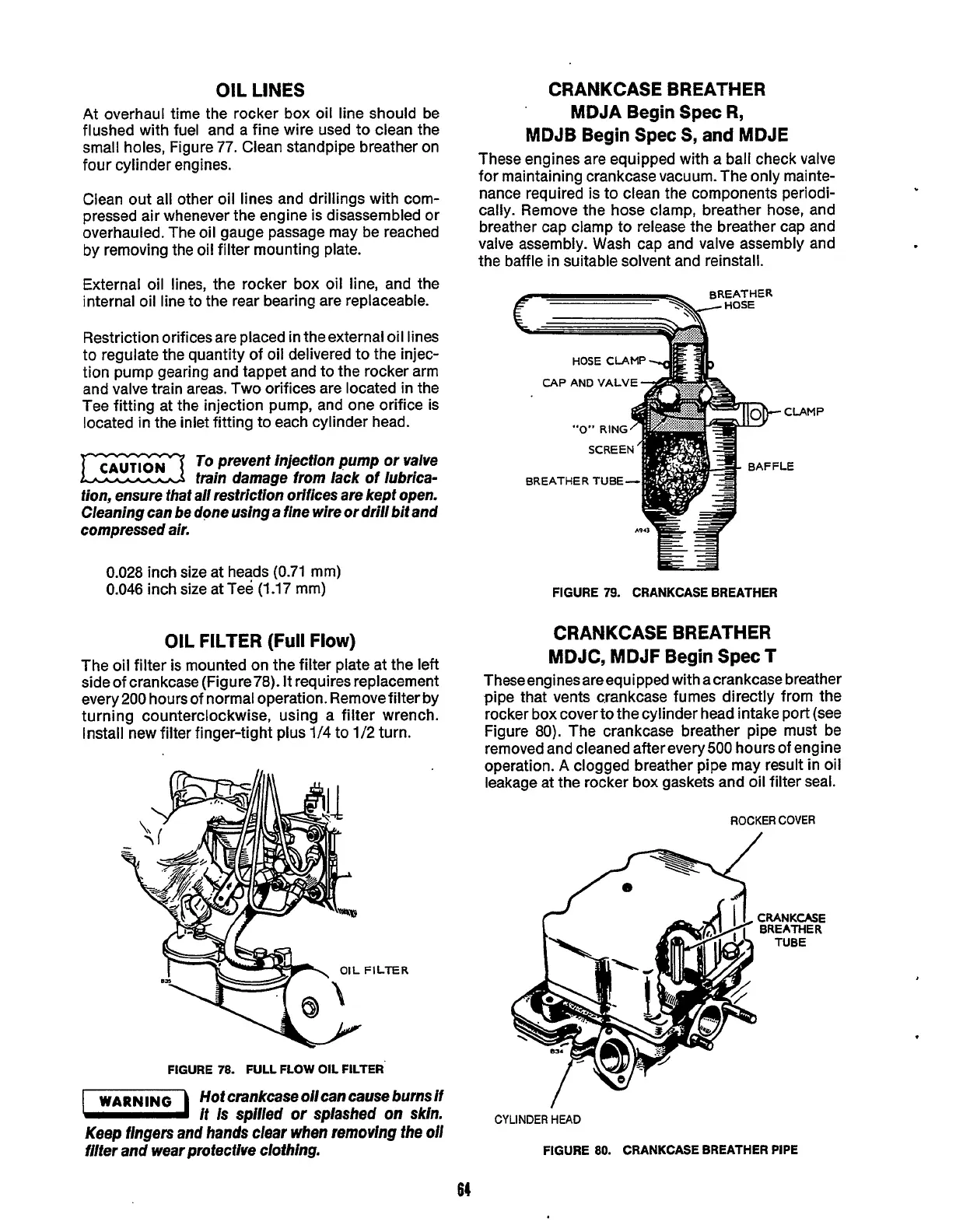

CRANKCASEBREATHER

'

MDJA Begin Spec

R,

MDJB Begin Spec

S,

and

MDJE

These engines are equipped with a ball check valve

for maintaining crankcase vacuum. The only mainte-

nance required is to clean the components periodi-

cally. Remove the hose clamp, breather hose, and

breather cap clamp to release the breather cap and

valve assembly. Wash cap and valve assembly and

the baffle in suitable solvent and reinstall.

CAP

AND

VALVE

BREATHER TUBE

FIGURE

79.

CRANKCASE BREATHER

AMP

CRANKCASEBREATHER

MDJC, MDJF Begin Spec

T

These eng

i

nes are equ

i

pped with a crankcase breather

pipe that vents c,rankcase fumes directly from the

rocker box coverto the cylinder head intake port (see

Figure 80). The crankcase breather pipe must be

removed and cleaned after every500 hours of engine

operation.

A

clogged breather pipe may result in oil

leakage at the rocker box gaskets and oil filter seal.

ROCKER

COVER

CYLINDER HEAD

FIGURE

80.

CRANKCASE BREATHER PIPE

64

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...