FRONT SUSPENSION

3A- 11

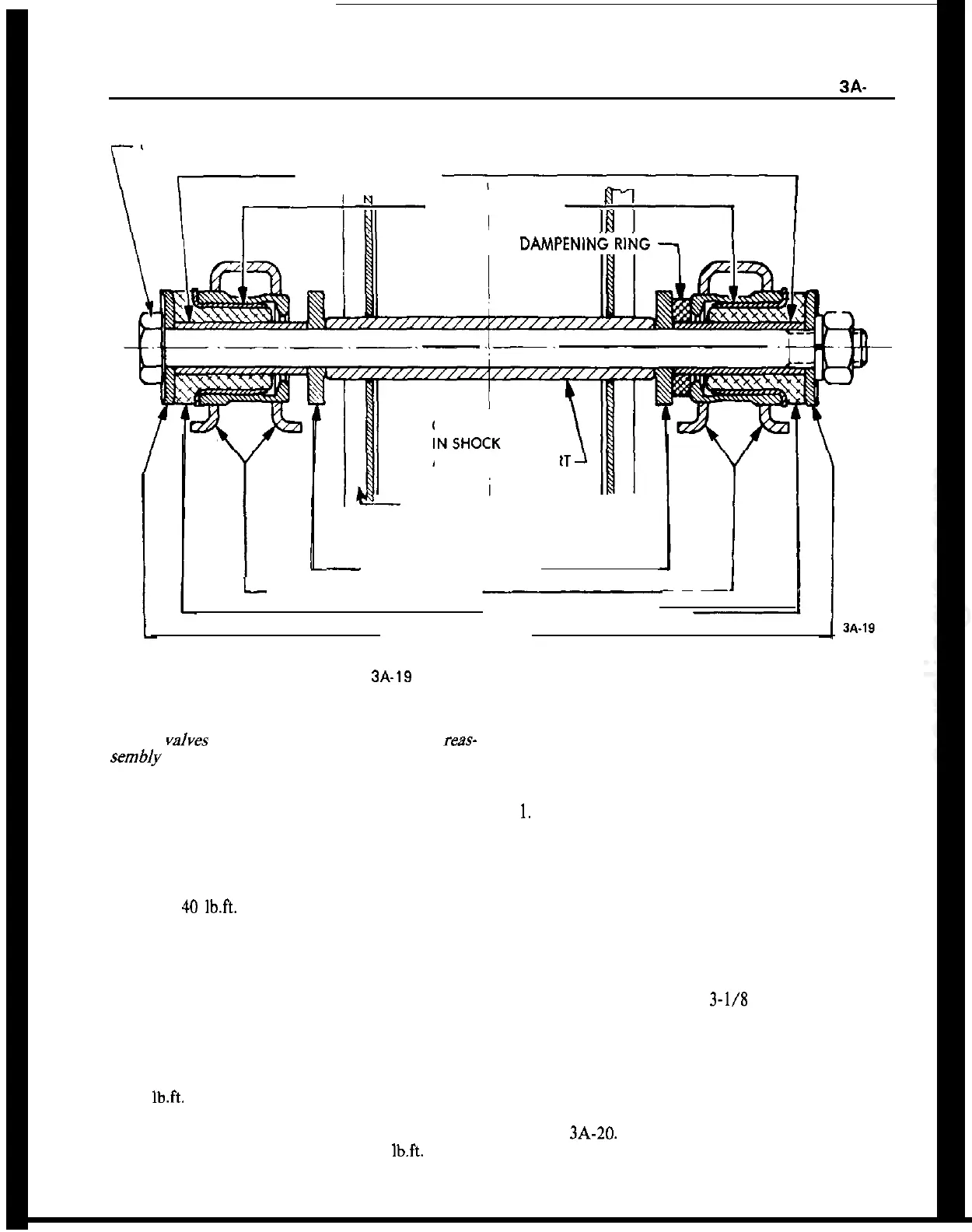

UPPER CONTROL ARM SHAFT

INNER SLEEVE

OUTER SLEEVE

RUBBER DAMPENIN

GUIDE SLEEVE

ABSORBER SUPPOR

SHOCK ABSORBER SUPPORT

ON FRONT SUSPENSION

CROSS MEMBER

-

TOOTHED WASHER

l-

UPPER CONTROL ARM

RUBBER BUSHINGS

PLATE WASHER

Figure

3A-19

Upper Control Arm Shaft and Bushings

placement part of lesser quality or substitute design.

Torque

valves

must be used as specified during

reas-

semb/y to assure proper retention of these parts.

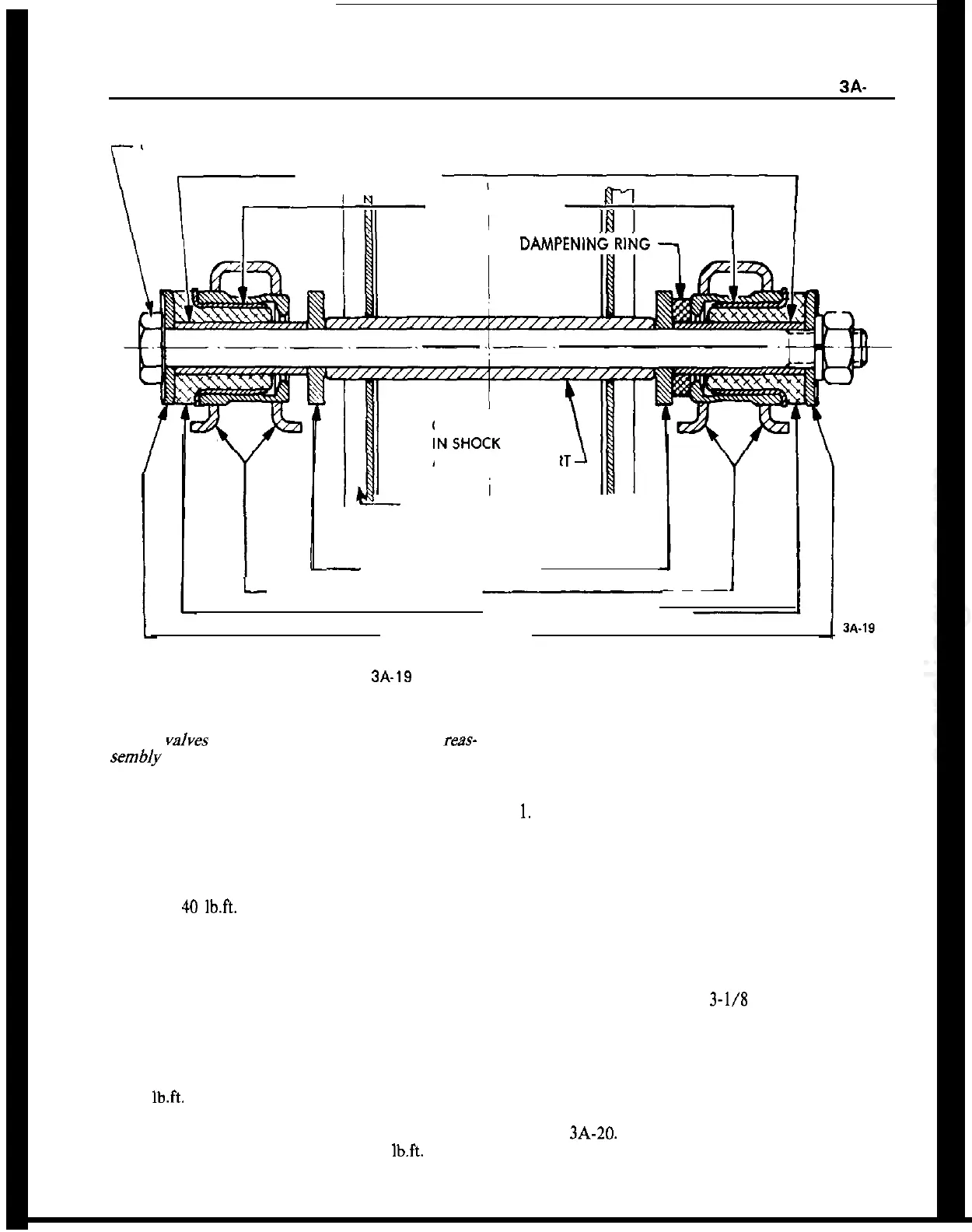

1. On installation of the upper control arm, make

sure that damper bushing with the rubber shoulder

on both sides is always located in the rear.

2. Attach upper control arm to cross member and

torque to

40

lb.ft.

Always use new self-locking hex

nut. The upper control arm must be tightened in

horizontal position only. This applies also to all other

attaching joints in connection with rubber damper

bushings in the control arms of the front suspension

so that the rubber parts under load are in an almost

twist-free condition. This position exists, if the hooks

J-23697 are used.

3. Attach ball joint to upper control arm and torque

to 29

lb.ft.

4. Install wheel and torque nuts to 65

lb.ft.

Lower

car.

LOWER CONTROL ARM REMOVAL AND

INSTALLATION

Removal GT

1.

Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. Remove cotter pin from castle nut on ball joint

stud and back off castle nut two (2) turns. Hit ball

stud a sharp blow to break it loose. DO NOT

REMOVE NUT.

4. Install spring compressor (J-21689) and compress

spring until a distance of

3-l/8

inches is achieved

between spring compressor and lower spring leaf.

5. Disconnect and compress shock absorber.

6. Support rail of spring compressor with a jack.

Remove lower control arm from frame cross mem-

ber. Nuts may have to be removed with a punch. See

Figure 3A-20. Discard the lock nuts.

7. Remove lower ball joint stud nut. Slightly lower

Loading...

Loading...