ENGINE MECHANICAL AND MOUNTS

6A- 15

New inlet valves must not be refaced or lapped with

grinding compound. The correct angle for the intake

and exhaust valve head is 44 degrees.

10. Install cylinder head.

11. Adjust valve clearance. See MAINTENANCE

AND ADJUSTMENTS.

7. Inspect valve guides. Worn or pitted guides can be

reamed to accept valves with oversize stems. Over-

size valves are occasionally used in production.

Oversize valves are marked

’

1

u

“2” or “A” and are

stamped into the valve stem end and also stamped

near spark plug hole. See Figure 6A-22.

Replacing Rocker Arm Studs

1. When replacing rocker arm studs become

neces-

sary,

remove air cleaner, rocker arm cover and

rocker arm.

8. Reseat valve seats in cylinder head in the following

sequence:

Intake

NOTE:

The rocker arm studs are screwed into the

cylinder head. A tapered part of the stem serves to

a void stud loosening.

With 45 degrees cutter, remove burnt structure until

a metallic bright seat is obtained. Lightly coat valve

head with red lead, insert it into guide and turn it

under light pressure several times back and forth.

Thereby a contact pattern is obtained and the seat

width can be measured. If valve does not seat per-

fectly all around, lightly recut valve seat to the estab-

lished seat width of

,049”

-

.059”

with 30 degrees

correction cutter.

Exhaust

The directions for reconditioning intake valve seats

apply in principle also to exhaust valve seat recondi-

tioning with the exception that the valve seat width

should be

.063-,073

in. and different cutters are em-

ployed.

NOTE:

:

OTse

new

valve

seals

whenever

valves are reconditioned.

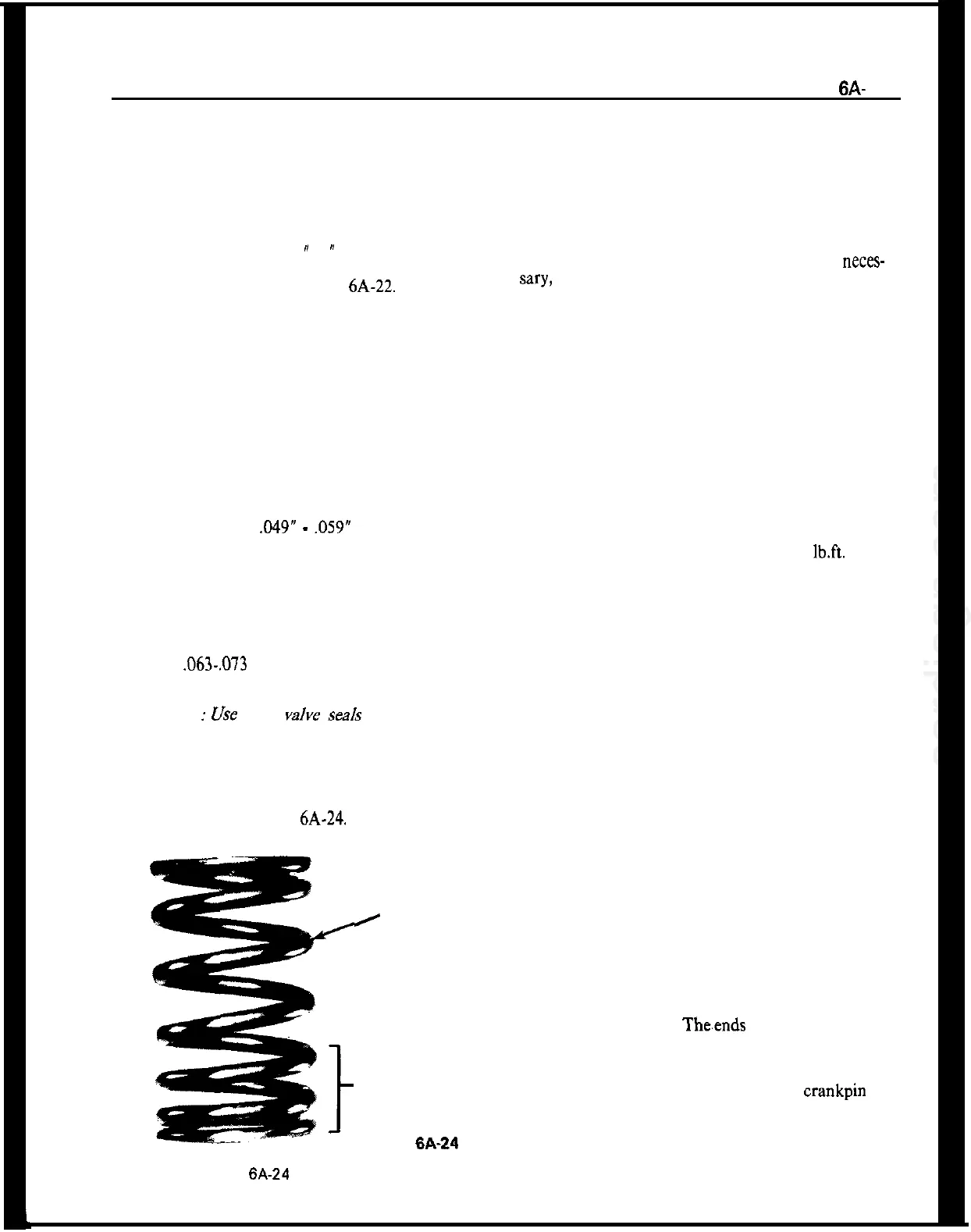

9. Lube valves with engine oil and reinstall valves,

valve springs, caps and cap retainers using J-8062.

Install valve spring with closely wound coils toward

cylinder head. See Figure

6A-24.

2. Attach vise grip pliers to stud being removed and

remove from cylinder head.

3. Screw in new stud. Seat tapered part of stud by

striking stud end with a rubber hammer.

4. Place two turned down rocker arm nuts on

threaded part of stud.

5. Torque stud into cylinder head to 29

lb.ft.

Valve Lifter Service

The valve lifters can be removed after removing

rocker arm cover and rocker arms.

No oversize lifters have been released due to the

insignificant wear of the valve lifters and cylinder

head guides.

Amply oil respective parts and install in reverse se-

quence to removal.

Carry out hydraulic valve lifter adjustment as ou-

tlined in MAINTENANCE AND ADJUST-

MENTS.

VALVE

I

SPRING

CLOSE

WOUND

COILS

TOWARD

HEAD

6A-24

Figure 6A-24 Valve Spring

CONNECTING ROD BEARINGS

A connecting rod bearing consists of two halves or

shells which are alike and interchangeable in rod and

cap. When the shells are placed in rod and cap the

ends extend slightly beyond the parting surfaces so

that when rod bolts are tightened the shells will be

clamped tightly in place to insure positive seating

and to prevent turning. Theends of shells must never

be tiled flush with parting surface of rod or cap.

If a precision type connecting rod bearing becomes

noisy or is worn so that clearance on crankpin is

excessive, a new bearing of proper size must be se-

lected and installed since no provision is made for

adjustment. Under no circumstances should the con-

necting rod or cap be filed to adjust the bearing

clearance.

Loading...

Loading...