ENGINE MECHANICAL AND MOUNTS 6A- 19

sion.

When replacing flywheel use new bolts and

torque to 43 lb.ft.

PISTON, RINGS AND CONNECTING RODS

Removal and Disassembly of Piston

and Rod Assemblies

1. Drain oil.

2. Remove oil pan.

3. Remove cylinder head.

4. Examine the cylinder bores above the ring travel.

If bores are worn so a ridge exists, remove the ridges

with a ridge reamer to avoid damaging rings or

cracking ring lands in pistons during removal.

5. Mark the cylinder number on all pistons, connect-

ing rods and caps. Starting at the front end of the

crankcase, the cylinders are numbered l-2-3-4,

6. Remove cap and bearing shell from number 1

connecting rod.

7. Push the piston and

rod assembly up and out of

top cylinder. Then reinstall cap and bearing shell on

rod.

0

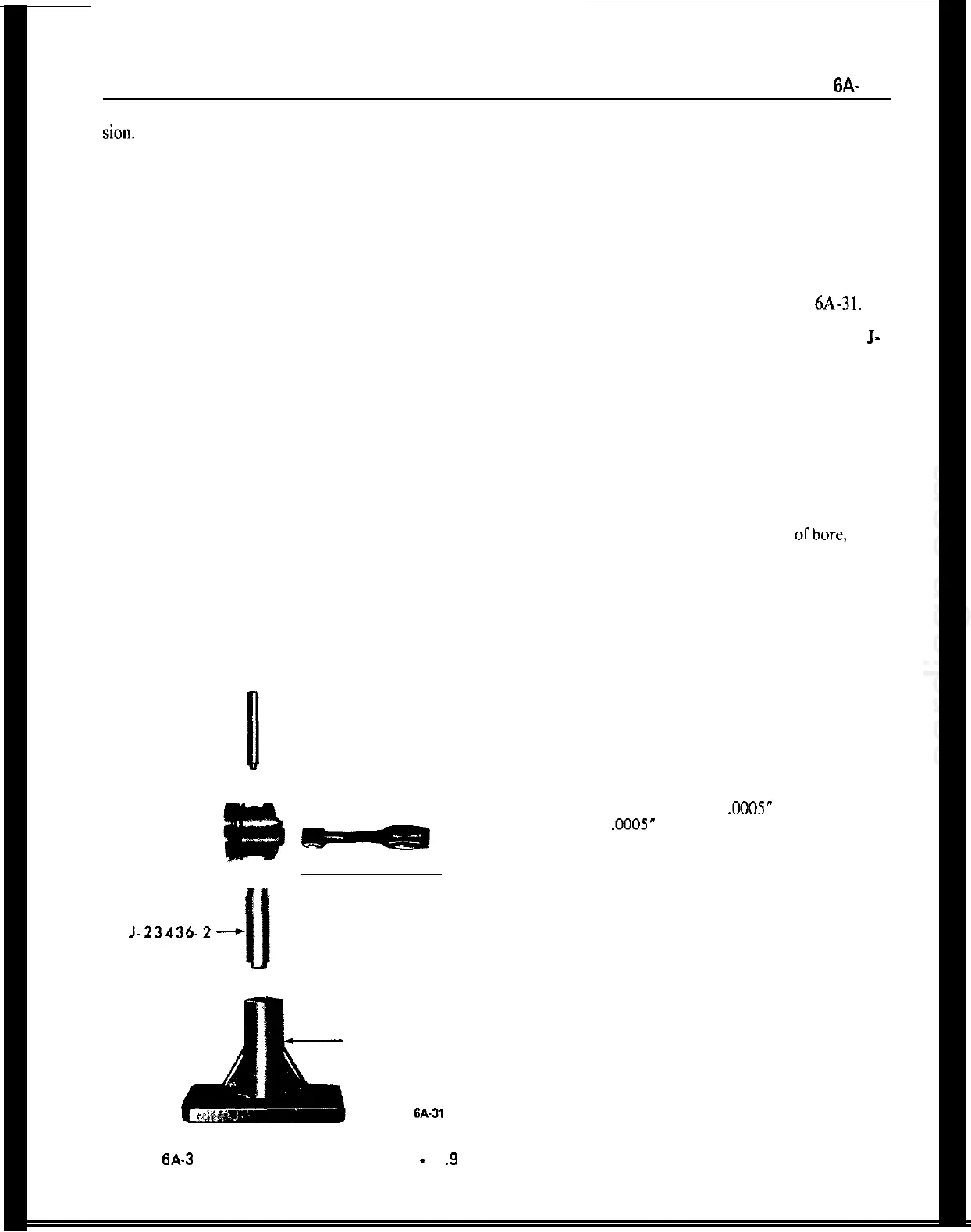

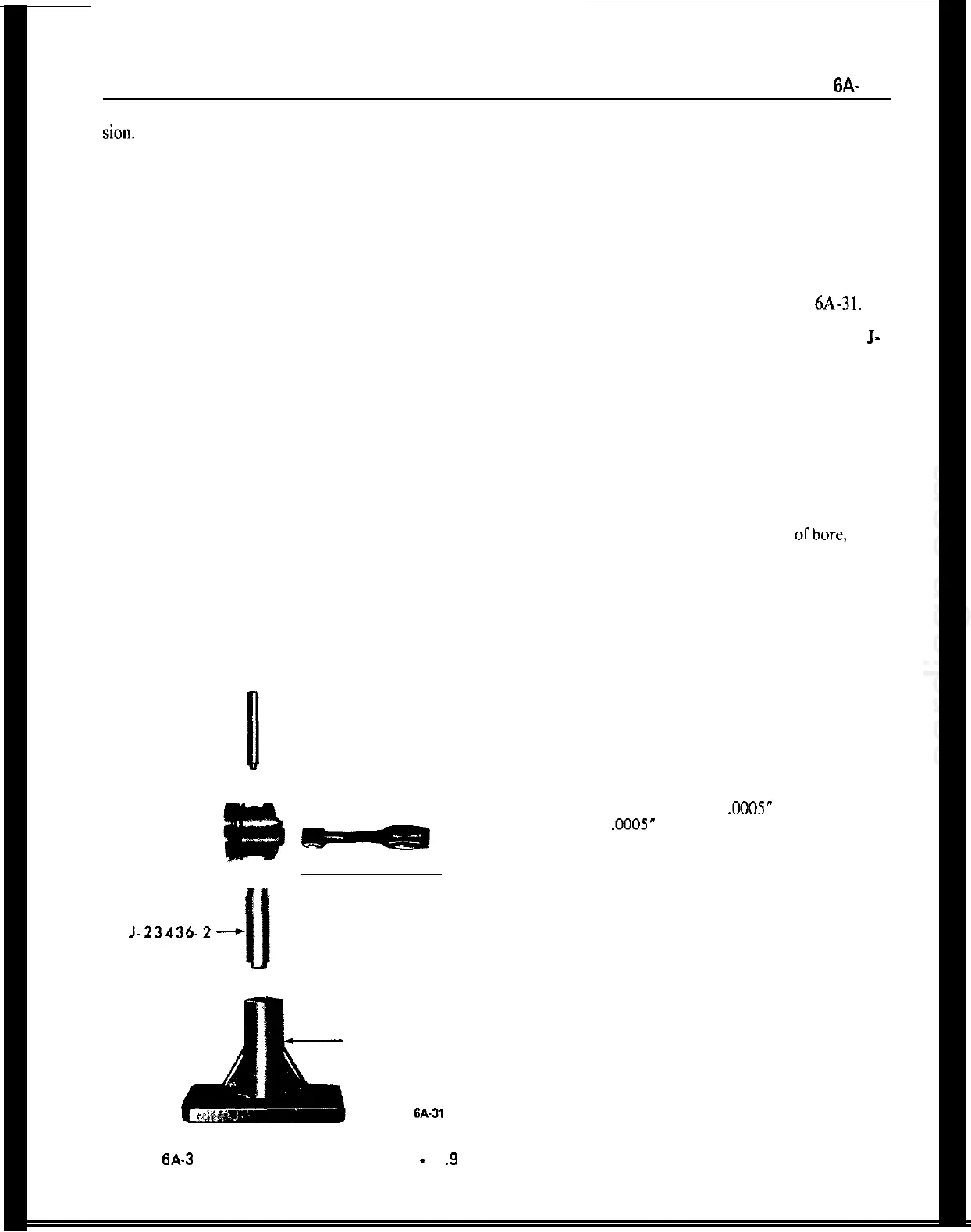

-J-23436-4

J-23436-2+

J-6047

Figure

6A-3

1 Piston Pin Removal Tool Layout - 1

.S

Engine

8. Remove other rod and piston assemblies in the

same manner.

9. Remove compression rings and oil rings.

10. Remove piston pin in following manner:

a. Position base support J-6047 on hydraulic press.

b. Place tool J-23436-2 in base support with large

diameter bore facing upward. See Figure

6A-31.

c. Position piston and rod assembly on tool

J-

23436-2 making certain the pin is aligned on tool.

d. Position tool J-23436-4 in opposite end of piston

pin and press pin out.

Inspection of Cylinder Bores

Inspect cylinder walls for scoring, roughness, or

ridges which indicate excessive wear. Check cylinder

bores for taper and out-of-round with an accurate

cylinder gage at top, middle and bottom

ofbore, both

parallel and at right angles to the centerline of the

engine. The diameter of the cylinder bores at any

point may be measured with an inside micrometer or

by setting the cylinder gauge dial at “0” and measur-

ing across the gauge contact points with outside mi-

crometer while the gauge is at the same “0” setting.

If a cylinder bore is moderately rough or slightly

scored but is not out-of-round or tapered, it is possi-

ble to repair the bore by honing to accept a standard

service piston. If cylinder bore is very rough or

deeply scored, it may be necessary to rebore the cyl-

inder to fit an oversize piston in order to insure satis-

factory results.

If a cylinder bore is tapered

.ooO5”

or more, or is

out-of-round

.0005”

or more, it is advisable to hone

or rebore for the smallest possible oversize piston and

rings.

Visual Inspection of Pistons, Rings, and Pins

Clean carbon from piston surfaces and under side of

piston heads. Clean carbon from ring grooves with a

suitable tool and remove any gum or varnish from

piston skirts with suitable solvent.

Carefully examine pistons for rough or scored bear-

ing surfaces, cracks in skirt, head cracked or broken

ring lands, and chipping or uneven wear which

would cause rings to seat improperly or have exces-

sive clearance in ring grooves. Damaged or faulty

pistons should be replaced.

Fitting Pistons to Cylinders

The pistons are cam ground, which means that the

Loading...

Loading...